Implants suitable for soft tissue repair

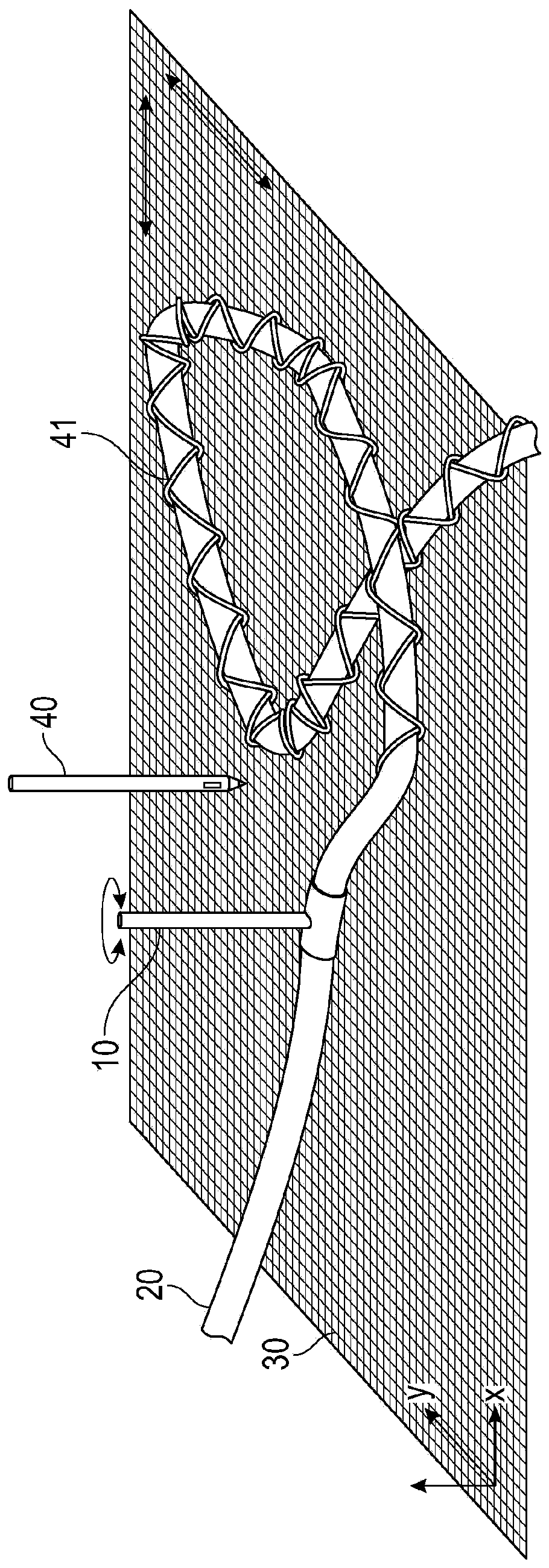

A yarn and helix technology, applied in the field of implants, can solve the problems of patients with postoperative pain, the inability of the patch to maintain enhanced function, and recurrence of prolapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

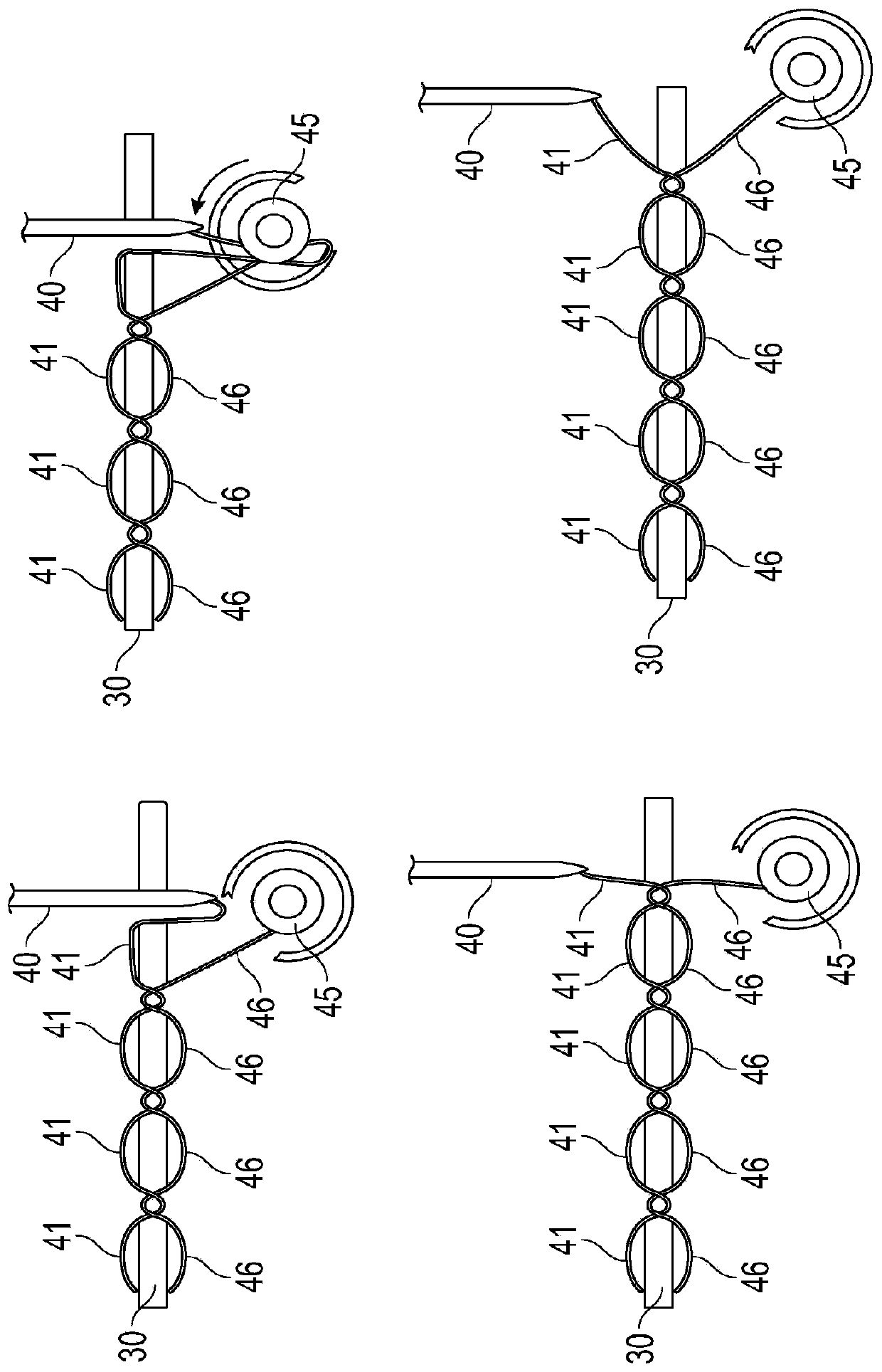

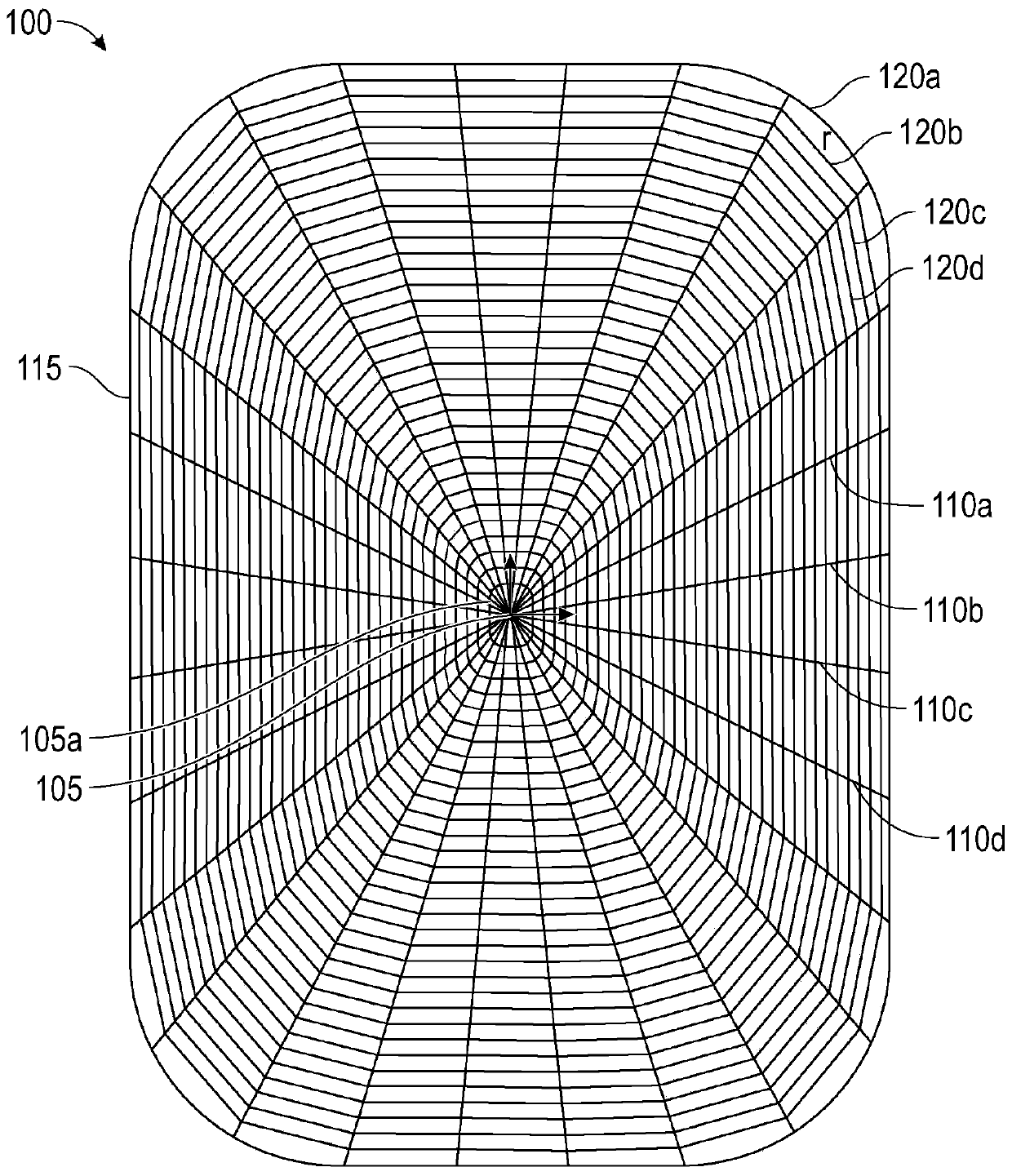

Method used

Image

Examples

example 1

[0261] Implantable meshes were prepared using TFP technology as described herein to combine monofilament radial yarns, monofilament helical yarns and Monofilament axial yarns are placed and secured on a dissolvable ground yarn. The radial monofilament yarn and the axial monofilament yarn were made of a copolymer of polytetrahydrofuran and polybutylene terephthalate (TPC), with a diameter of 210 μm, respectively. The helical monofilament yarn is made of polypropylene (PP) and has a diameter of 300 μm. The first threading multifilament yarn and the second threading multifilament yarn were made of 30Tex polyethylene terephthalate (PET). The soluble base yarn is made of non-woven water-soluble polyvinyl alcohol (PVA).

example 2

[0263] Implantable meshes were prepared using TFP technology as described herein to combine monofilament radial yarns, monofilament helical yarns and Monofilament axial yarns are placed and secured on a dissolvable ground yarn. The radial monofilament yarn and the axial monofilament yarn are made of a copolymer of polytetrahydrofuran and polybutylene terephthalate (TPC), with a diameter of 400 μm, respectively. The helical monofilament yarn is made of polypropylene (PP) and has a diameter of 300 μm. The first threading multifilament yarn and the second threading multifilament yarn were made of 30Tex polyethylene terephthalate (PET). The soluble base yarn is made of non-woven water-soluble polyvinyl alcohol (PVA).

example 3

[0265] Implantable meshes are prepared using TFP technology as described herein to combine monofilament vertical yarns, monofilament horizontal yarns, monofilament Filament diagonal yarns and monofilament helical yarns are placed and fixed on a dissolvable ground yarn. Horizontal monofilament yarns, vertical monofilament yarns, and diagonal monofilament yarns were made from copolymers of polytetrahydrofuran and polybutylene terephthalate (TPC), each with a diameter of 210 μm. The helical monofilament yarn is made of polypropylene (PP) and has a diameter of 300 μm. The first threading multifilament yarn and the second threading multifilament yarn were made of 30Tex polyethylene terephthalate (PET). The soluble base yarn is made of non-woven water-soluble polyvinyl alcohol (PVA).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com