Center deviation measuring device and method based on liquid lens

A liquid lens, deviation measurement technology, applied in measurement devices, optical devices, instruments, etc., can solve the problems of limiting measurement range, affecting measurement accuracy, and low measurement efficiency, avoiding mechanical vibration, ensuring measurement accuracy, and improving measurement. The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

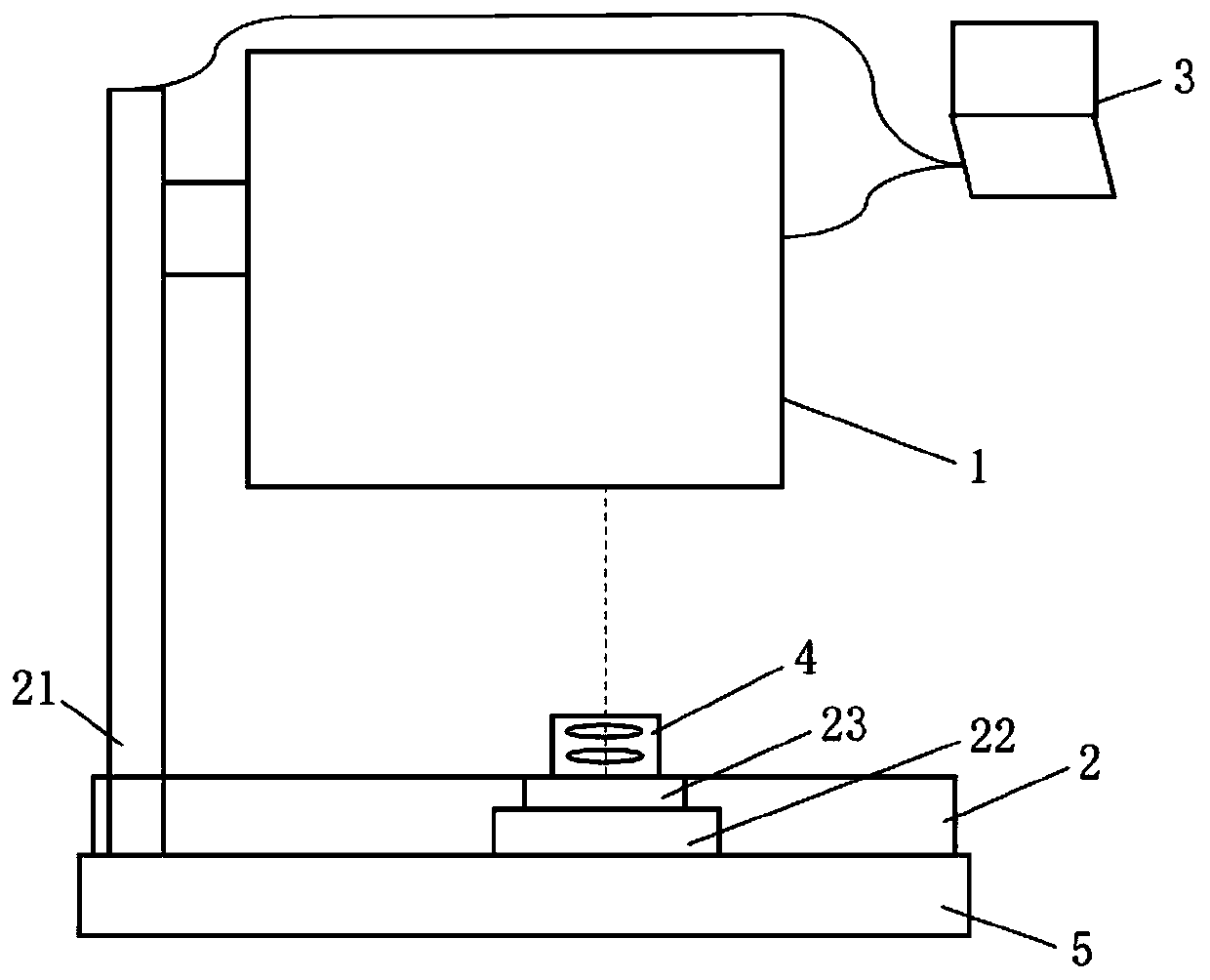

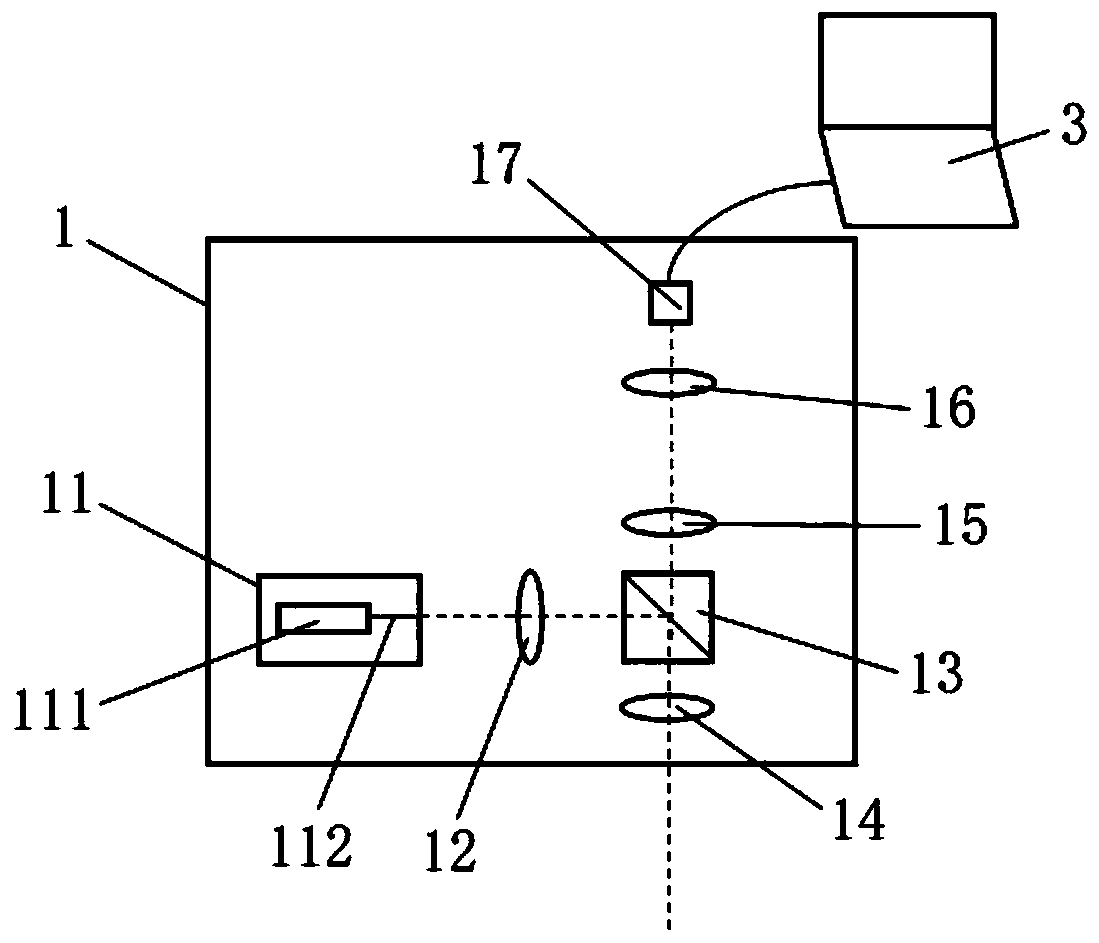

[0034] Such as figure 1 As shown, a center deviation measurement device based on a liquid lens in the present invention includes an optical measurement module 1 , a mechanical adjustment module 2 , a main control computer 3 and an optical platform 5 . The mechanical adjustment module 2 is installed on the optical table 5; the optical measurement module 1 is installed in combination with the mechanical adjustment module 2, and the mechanical adjustment module 2 drives the optical measurement module 1 along a direction perpendicular to the horizontal plane Move; the optical lens 4 to be measured is placed on the mechanical adjustment module 2, and the optical lens 4 is adjusted in orientation by the mechanical adjustment module 2, and is aligned with the optical measurement module 1 in a direction perpendicular to the horizontal plane; the main control The computer 3 is electrically connected to the optical measurement module 1 and the mechanical adjustment module 2, and the mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com