Environmental chamber temperature uniformity testing method and sample containing device

A technology for holding devices and testing methods, which is applied to measuring devices, thermometers, and parts of thermometers, etc., and can solve problems such as unsafe conditions and heavy human loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A method for testing the temperature uniformity of an environmental chamber, comprising the following steps:

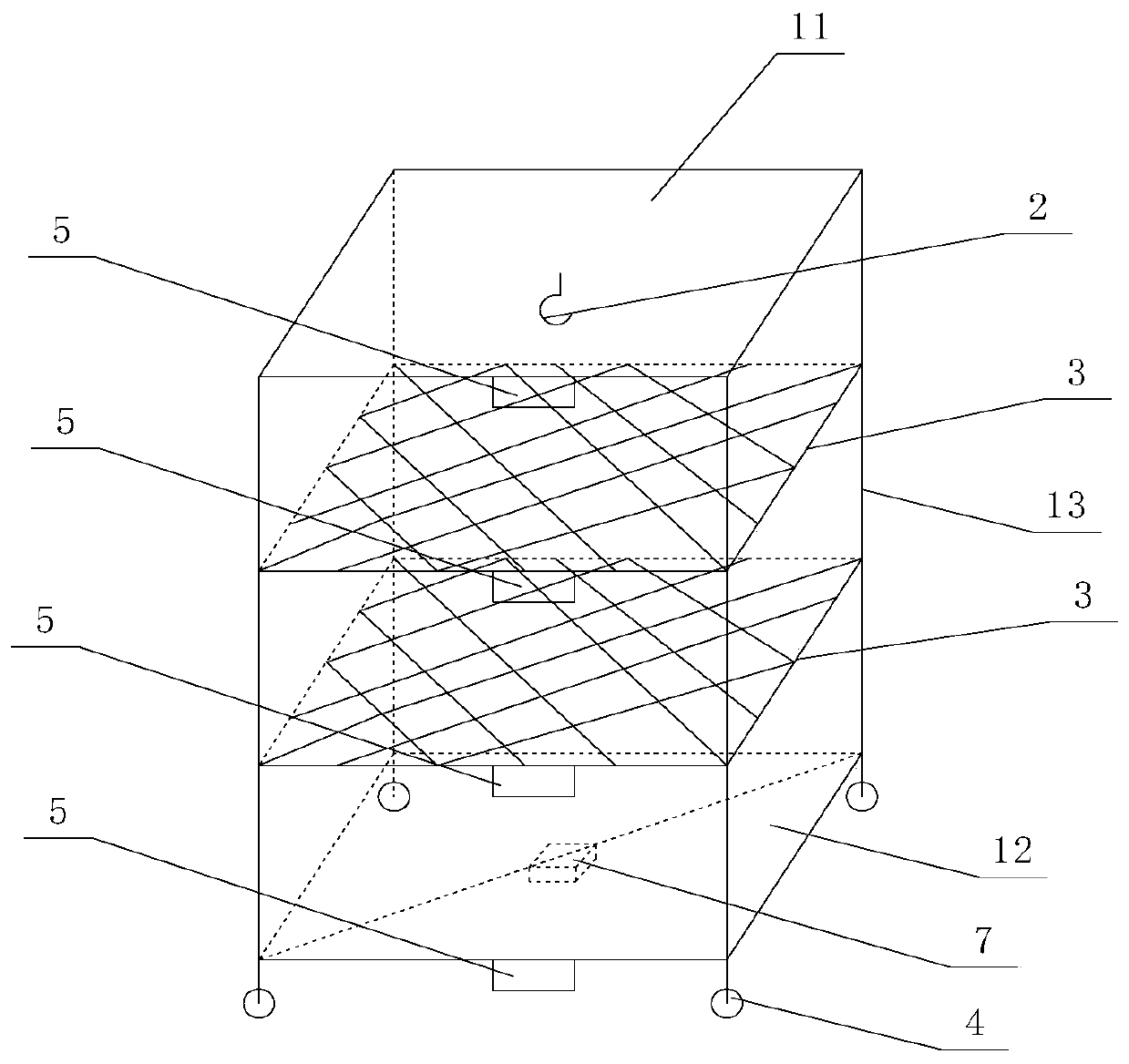

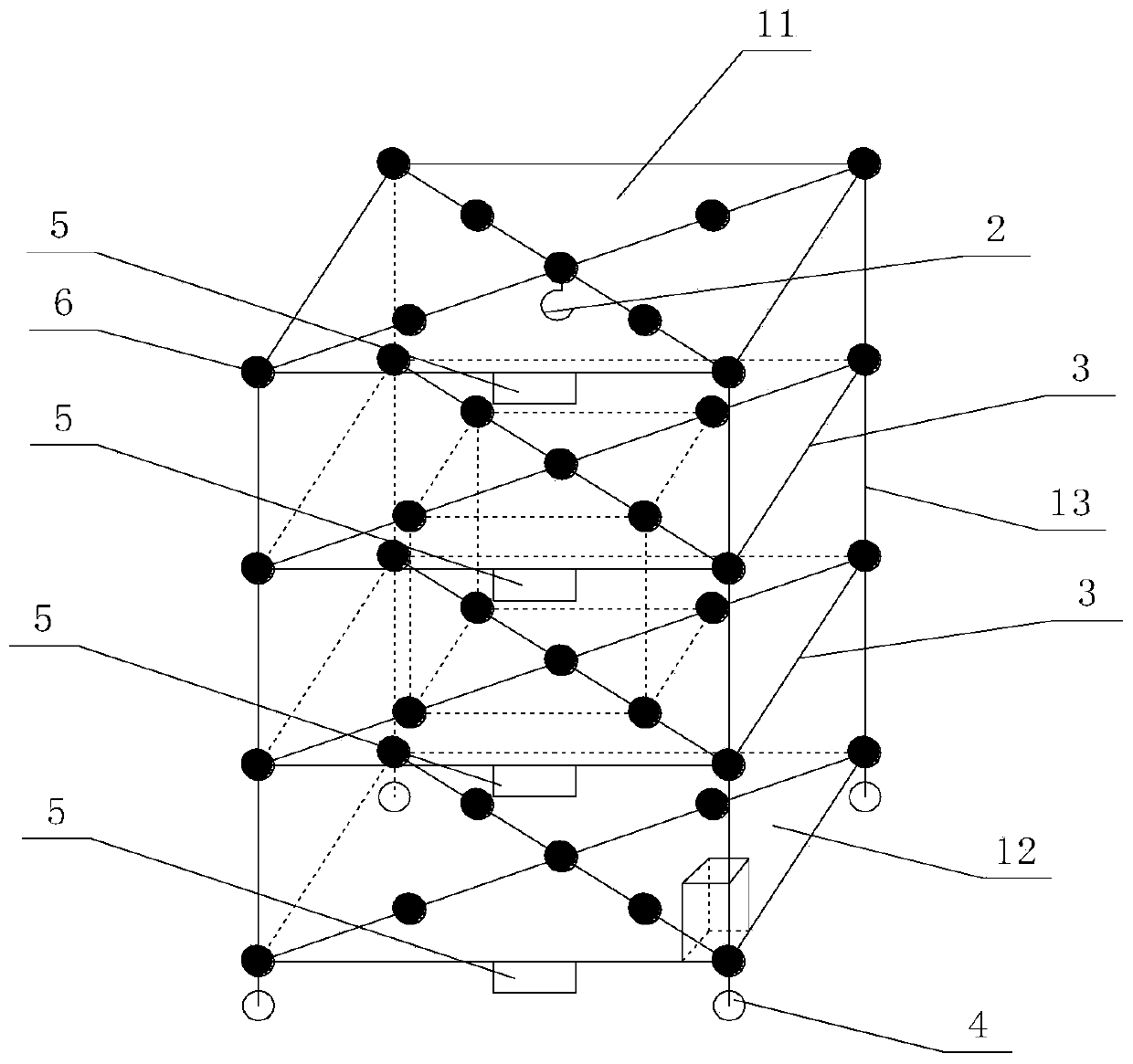

[0036] S1, make a sample rack, the sample rack includes a frame structure and a panel wrapping the frame structure, the top of the frame structure is used as a mounting layer 11, and the mounting layer 11 is provided with a hook 2 inside the frame, and the bottom plate 12 is used for Equipped with testing equipment and necessary to hold heavy samples, the base plate 12 and the mounting layer 11 are connected by a vertical support column 13, and several load-bearing layers 3 parallel to the base plate 12 are also arranged on the vertical support column 13;

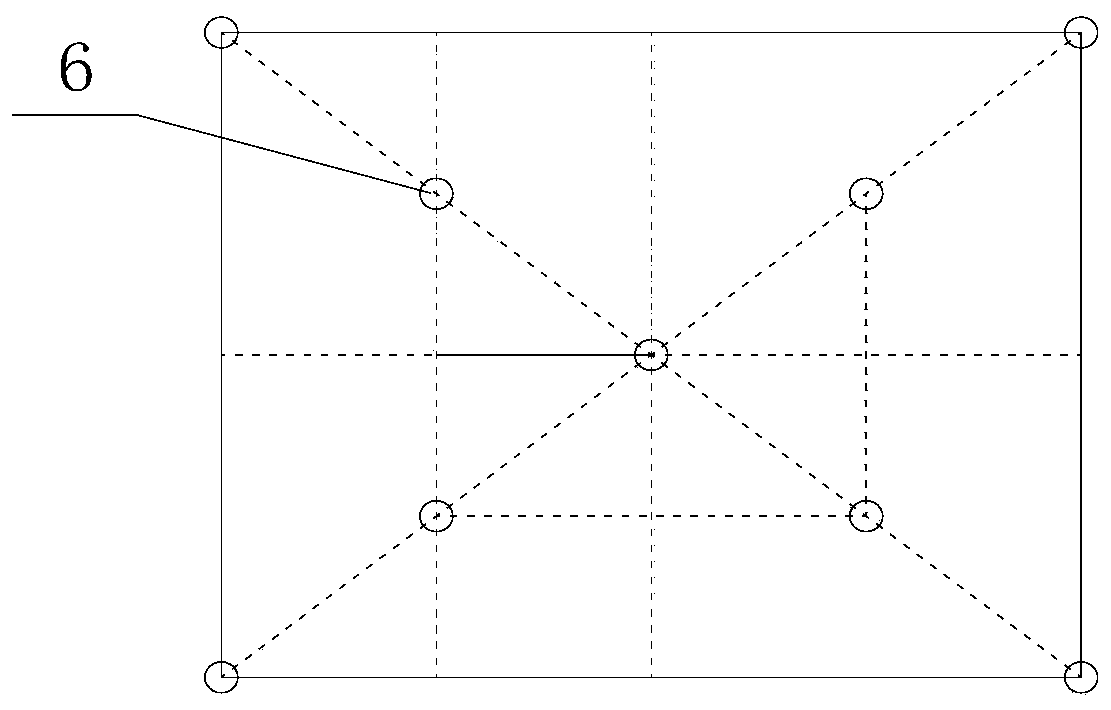

[0037] S2, a temperature sensor 6 is set at each corner and the bearing layer 3 in the frame structure of the sample holder;

[0038] S3. Move the position of the sample rack in the environmental chamber, obtain the values of all temperature sensors on the sample rack in each position, and calculate the st...

Embodiment 2

[0043] The sample holding device made according to embodiment 1, such as figure 1 As shown, a sample rack is included, and the sample rack includes a frame structure and a panel that wraps the frame structure, and the panel is transparent, so that the state in the environmental chamber can be obtained. The size specification of the frame structure is 1650*1300*850mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap