Self-aligning roller visual inspection machine

A self-aligning roller and detection machine technology, applied in sorting and other directions, can solve problems such as insufficient detection, and achieve the effects of convenient blanking, improved detection quality and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

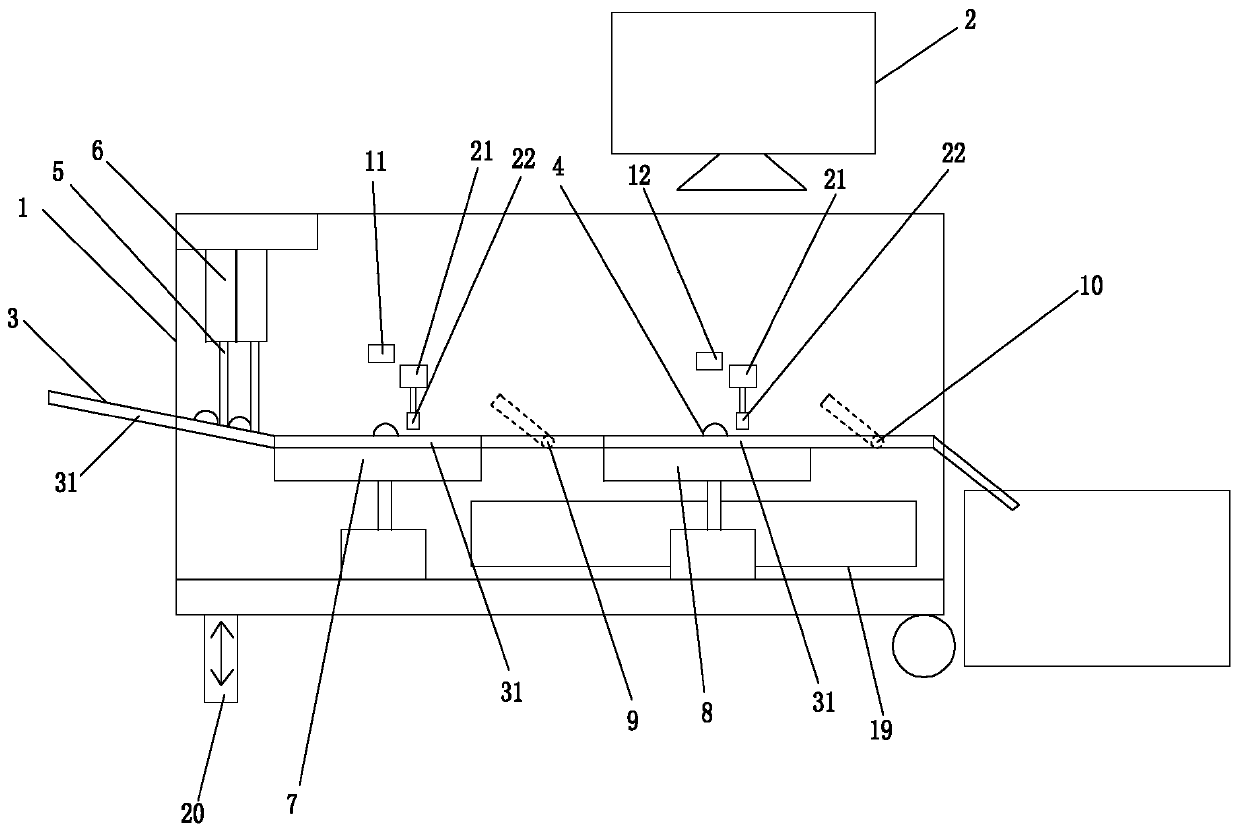

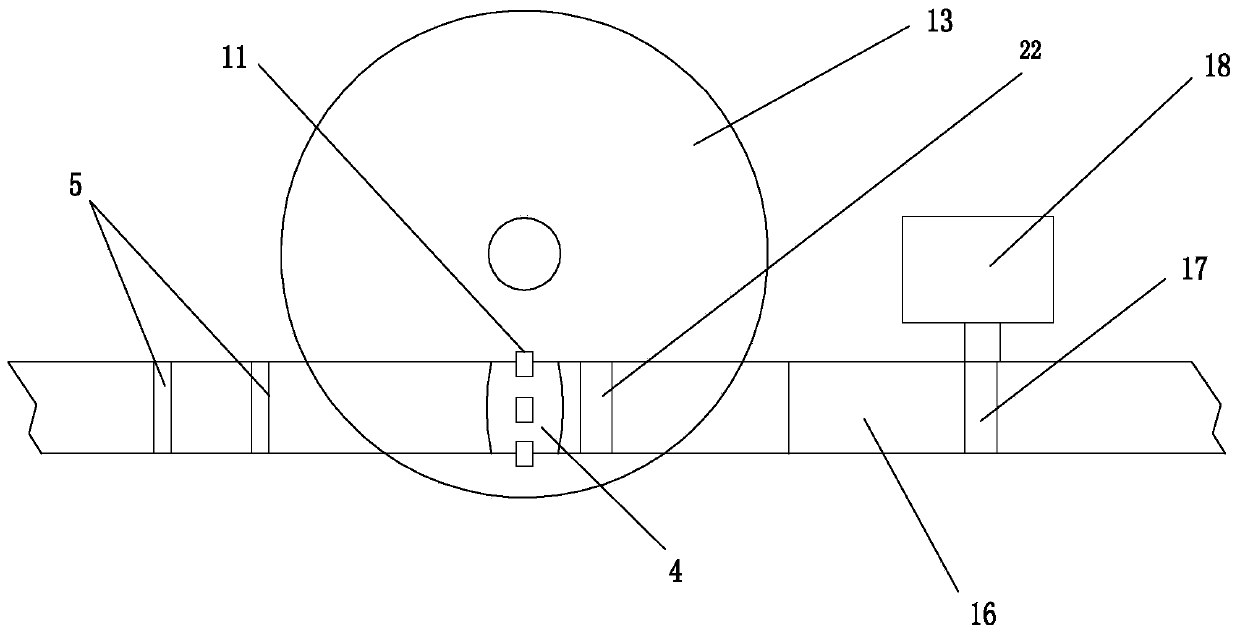

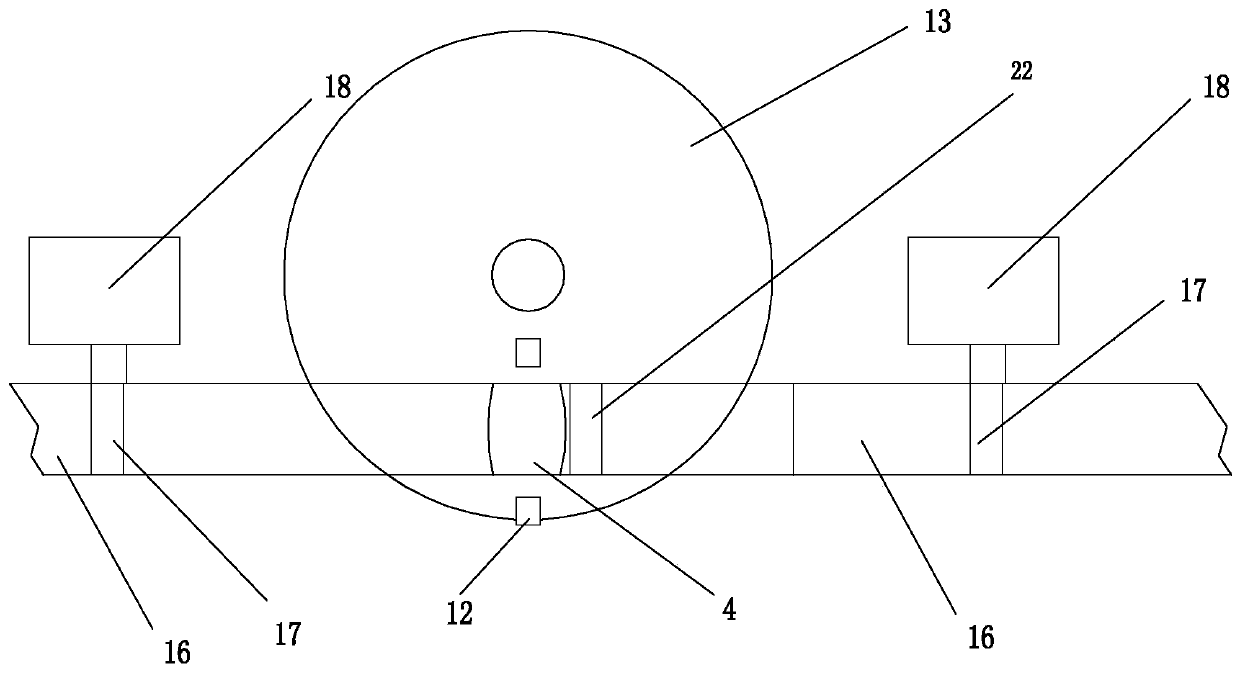

[0021] Such as Figure 1-Figure 4 As shown, the self-aligning roller visual inspection machine of the present invention includes a frame 1, a PC machine 2 filled with visual inspection software, a feeding channel 3, a quantitative delivery mechanism, a first roller rotation drive device 7, a second roller The rotary driving device 8, the first rejecting mechanism 9, the second rejecting mechanism 10, the roller surface detection camera group 11 and the roller end face camera group 12, the feeding channel 3 is arranged obliquely downward at the head of the frame 1, and the feeding The channel includes a base plate and side plates 31 arranged on both sides of the base plate. The base plate and the two side plates form the unloading area of the self-aligning roller 4, and the quantitative conveying mechanism is arranged in the second half of th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap