Large diameter polarized wire grid winding device

A technology of polarized wire grid and winding device, which is used in transportation and packaging, thin material handling, transportation of filamentous materials, etc., can solve personal and equipment safety accidents, imprints on the surface of materials, and cannot meet multiple windings, etc. problems, to prevent wire breakage or wire slack, improve control accuracy and speed, and improve reliability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] Embodiments of the present invention are described in detail below, and the embodiments are exemplary and intended to explain the present invention, but should not be construed as limiting the present invention.

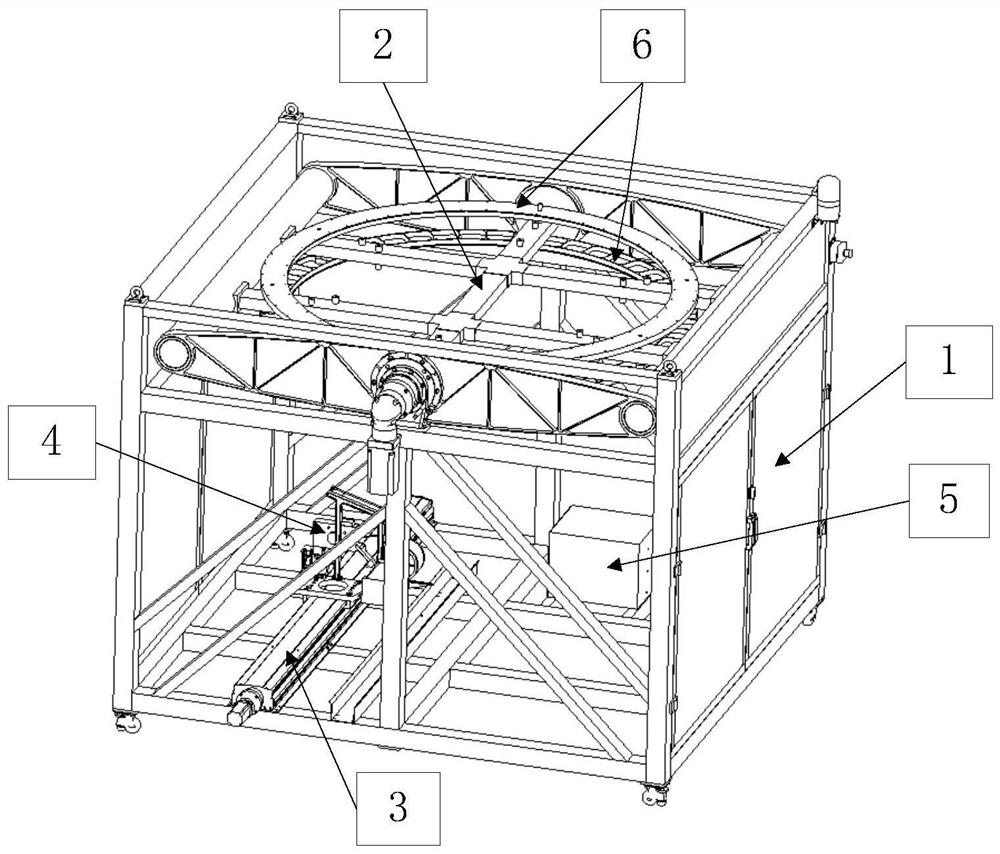

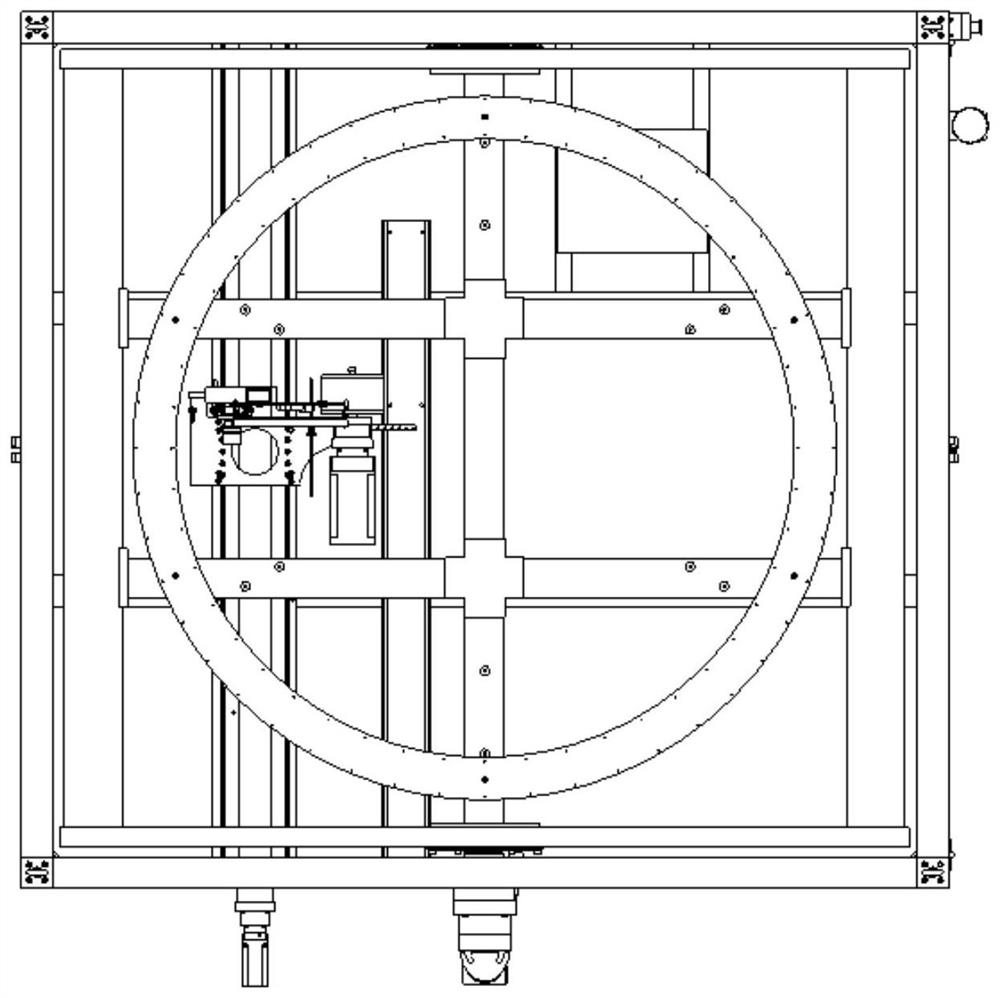

[0062] The structural schematic diagram of the polarized wire grid winding device in this embodiment is as follows figure 1 shown. It mainly includes working platform, winding mechanism, wire arranging mechanism, pay-off mechanism, control unit, etc. Its working principle is that the uniform rotational motion of the winding mechanism and the linear motion of the wire arranging mechanism synthesize the equidistant spiral motion of the metal wire, thus forming Equidistant linear array.

[0063] The working platform provides the installation interface of the winding mechanism, the cable arrangement mechanism and the control box.

[0064] The winding mechanism is located in the upper center of the working platform, and is installed on the working platform throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com