Building decorative board hoisting device capable of reducing wear rate

A technology for architectural decoration and hoisting equipment, which is applied in the direction of construction, building structure, lighting and heating equipment, etc. It can solve the problems of increasing the damage rate of the board, falling of the decorative board, and cumbersome fixing process, so as to facilitate the observation of the surrounding environment, The effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

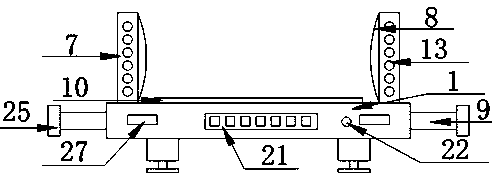

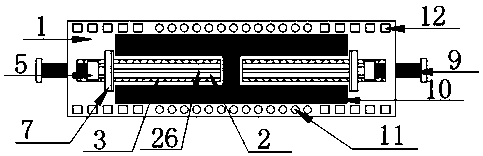

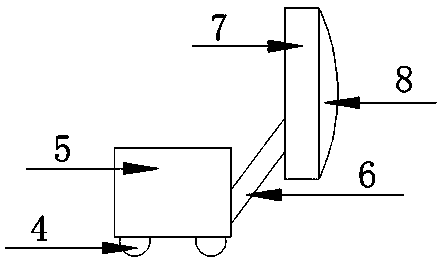

[0031] Embodiment one, such as Figure 1-6 As shown, according to an embodiment of the present invention, a hoisting device for building decorative panels capable of reducing the wear rate includes a base 1, a protective pad 10 is provided at the center of the top of the base 1, and the top sides of the base 1 are located at the The middle part of the protective pad 10 is provided with a chute 2, and the inner middle part of the chute 2 is provided with a guide rod 26. Both sides are provided with slide rails 3, and a motor 5 is provided in the chute 2, and a plurality of pulleys 4 are provided at the bottom of the motor 5, and the pulleys 4 cooperate with the slide rails 3, and the A motor shaft 9 is provided at the center of one side of the motor 5, and the outer surface of the motor shaft 9 is provided with threads, and the connection between the base 1 and the motor shaft 9 is provided with a circular threaded hole. The threads on the outer surface of the motor shaft 9 co...

Embodiment 2

[0032] Embodiment two, such as Figure 5 As shown, there is a circular through hole at the center of the bottom of the load bearing block 16, the load bearing block 16 is slidingly connected with the support column 19 through the circular through hole, the guide rod 26 is made of high alloy steel material, The bottom of the motor 5 is provided with a circular through hole matching with the guide rod 26 , and the guide rod 26 is slidably connected to the motor 5 through the through hole.

Embodiment 3

[0033] Embodiment three, such as figure 1 As shown, the suspension ring 27 is a semi-circular structure, the suspension ring 27 is made of low-alloy steel material, the top plate 18, the support column 19 and the bottom plate 20 are all made of high-alloy steel material, The side of the motor shaft 9 away from the motor 5 is provided with a limiting block 25 , the limiting block 25 is a cylindrical structure, and the diameter of the limiting block 25 is larger than the diameter of the threaded hole on the side of the base 1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com