Working method for multifunctional electric drill convenient to machine

A working method and multi-functional technology, applied in the field of processing tools, can solve the problems of night work obstruction, easily damaged signal processing module, hand injury, etc., to avoid the decline of drilling quality, facilitate night work, and accurately drill inclined holes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations.

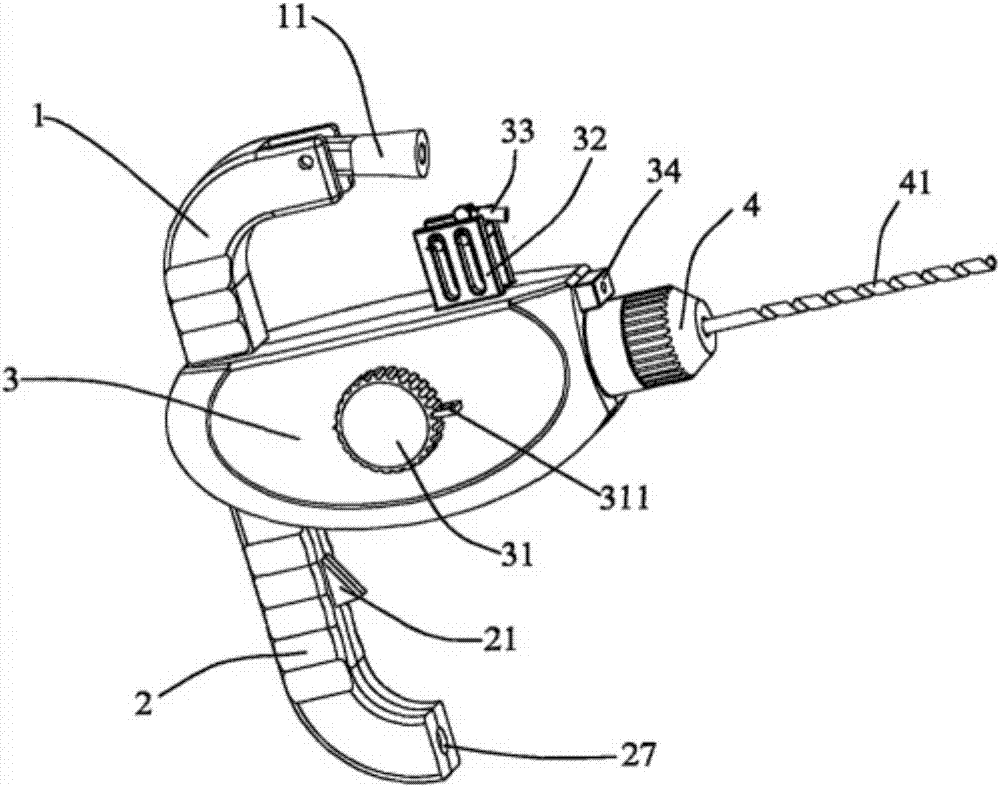

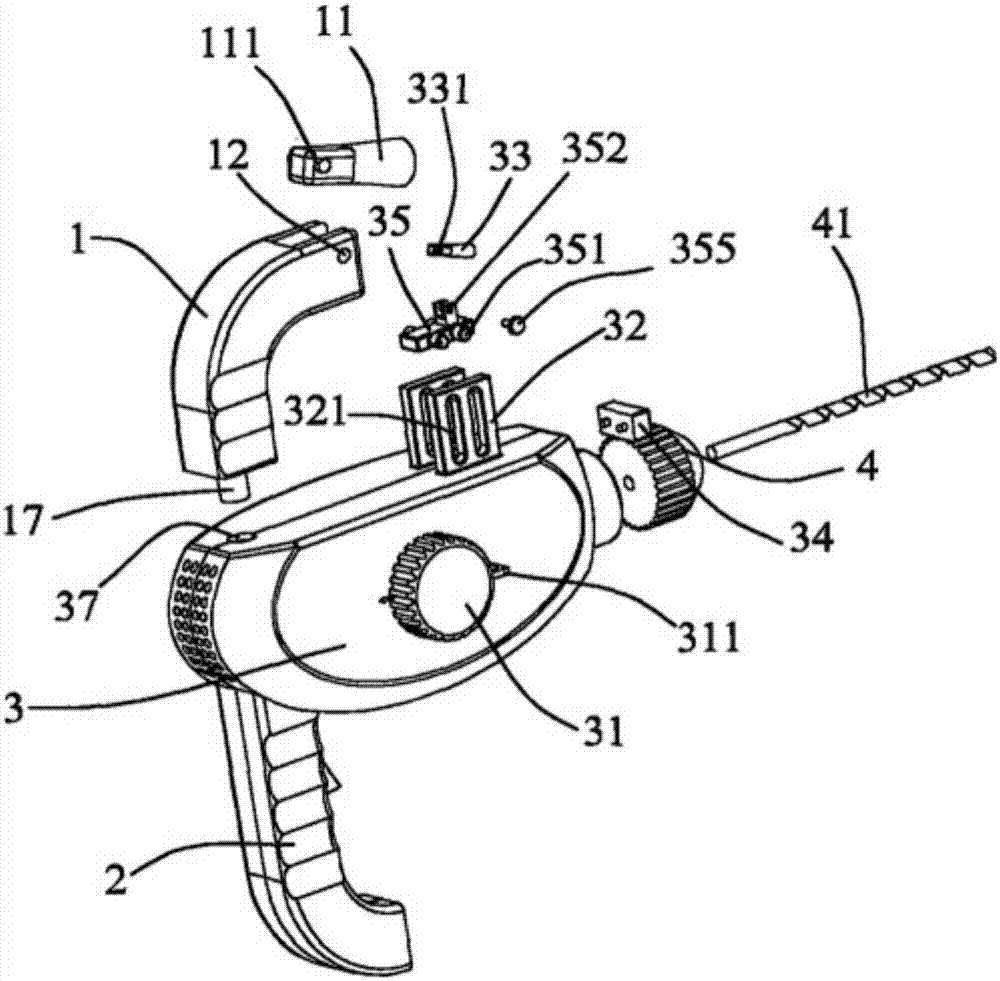

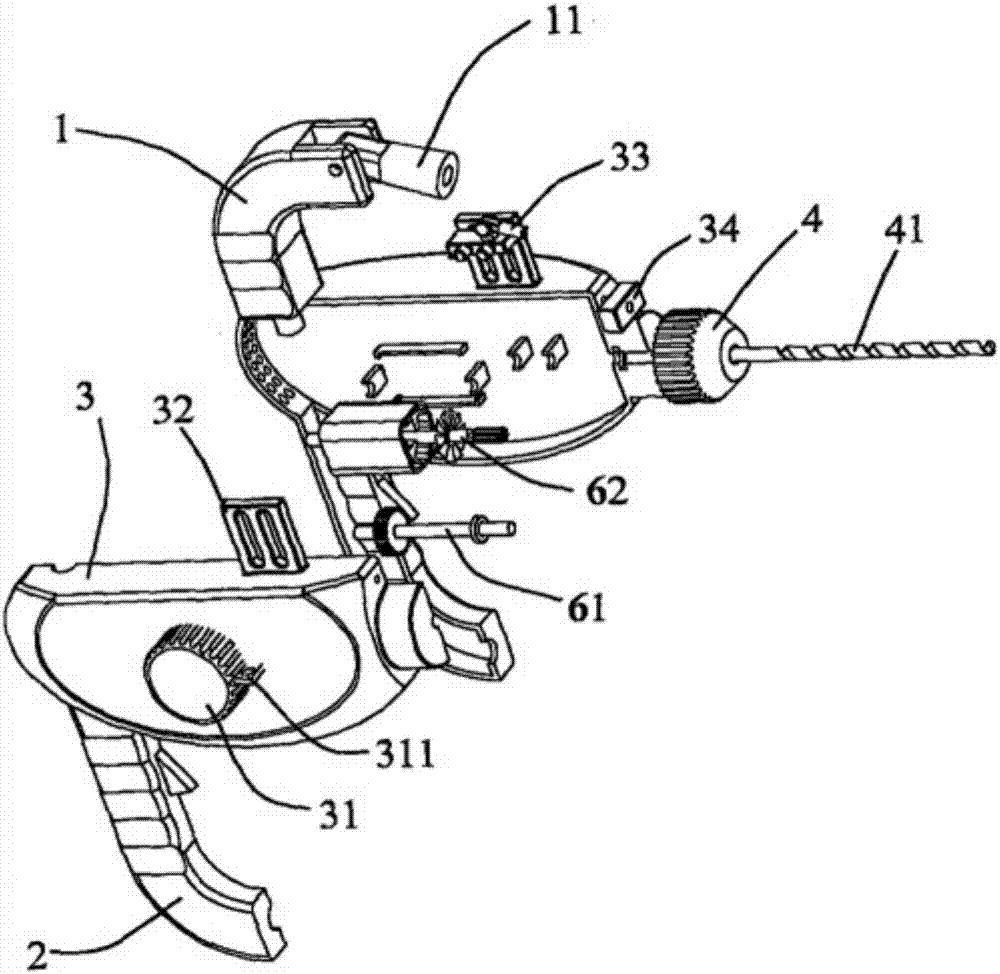

[0024] See Figure 1 to Figure 3 , a kind of multifunctional electric drill that is convenient to process, comprises the electric drill main body 3 that is provided with driving mechanism, and described electric drill main body 3 is provided with the handle that holds for hand, the drill head that is used for drilling, and described drill head includes drill bit holder 4 and the drill bit 41 located on the drill bit holder 4, also includes a first laser lamp 33 and a second laser lamp 34, the beams emitted by the first laser lamp 33 and the second laser lamp 34 intersect at one point, and the first laser lamp Lamp 33 is movably connected on the electric drill.

[0025] In this embodiment, the first laser l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com