Alloy gas storage bottle lined with plastic bottle or resin bottle and manufacturing method thereof

A gas storage bottle and plastic bottle technology, which is applied in the field of gas storage cylinders, hydrogen storage cylinders or oxygen cylinders, and can solve problems such as large stress deformation and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

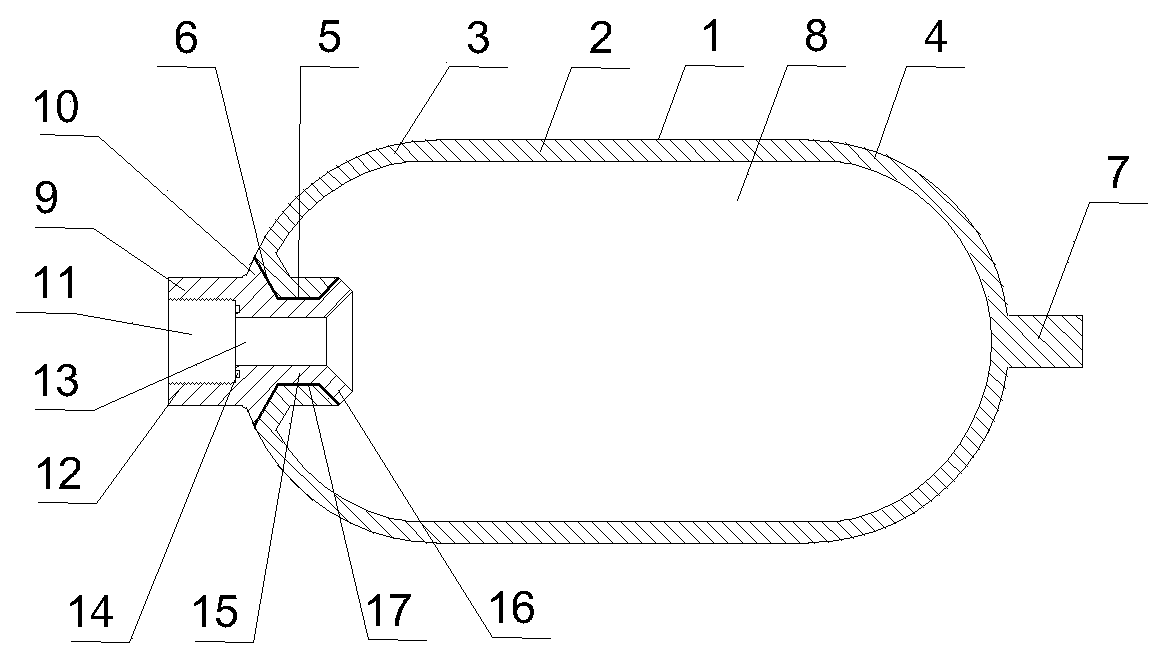

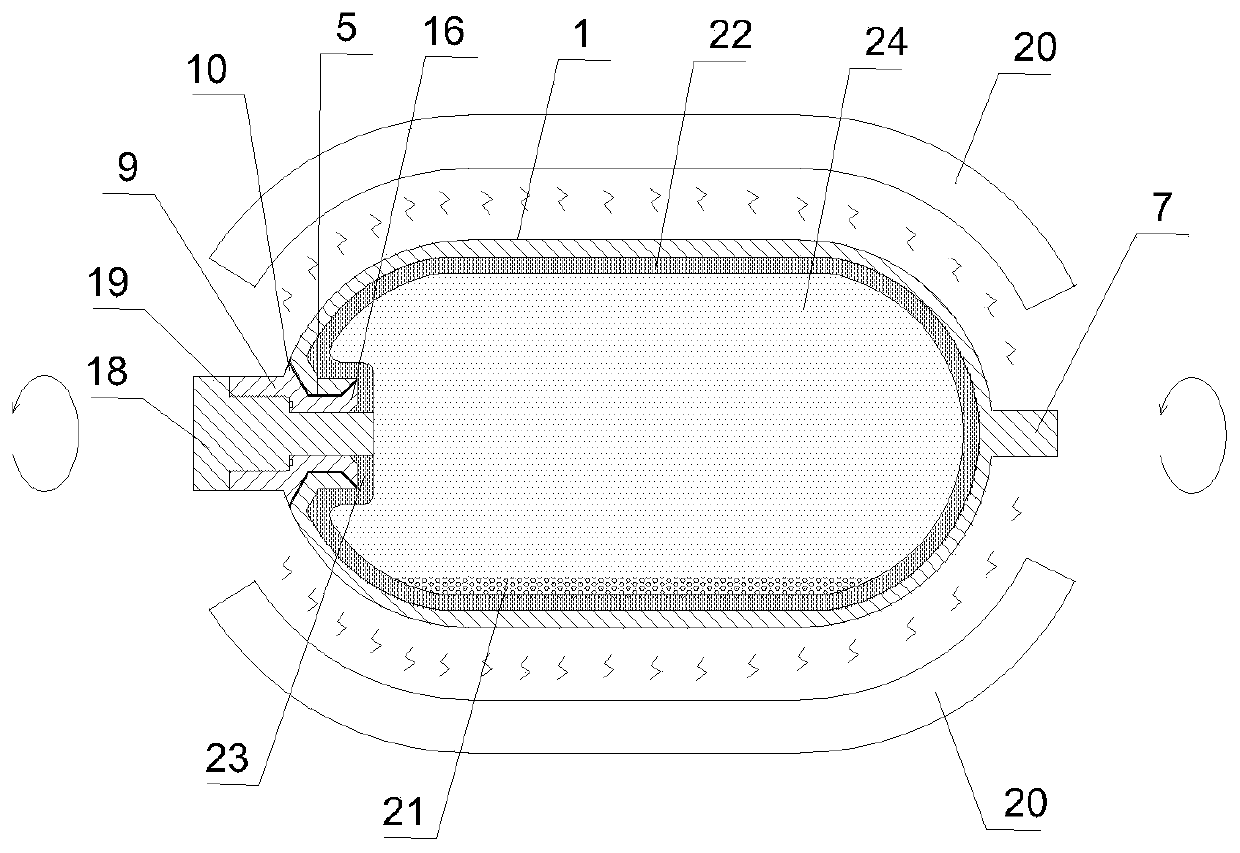

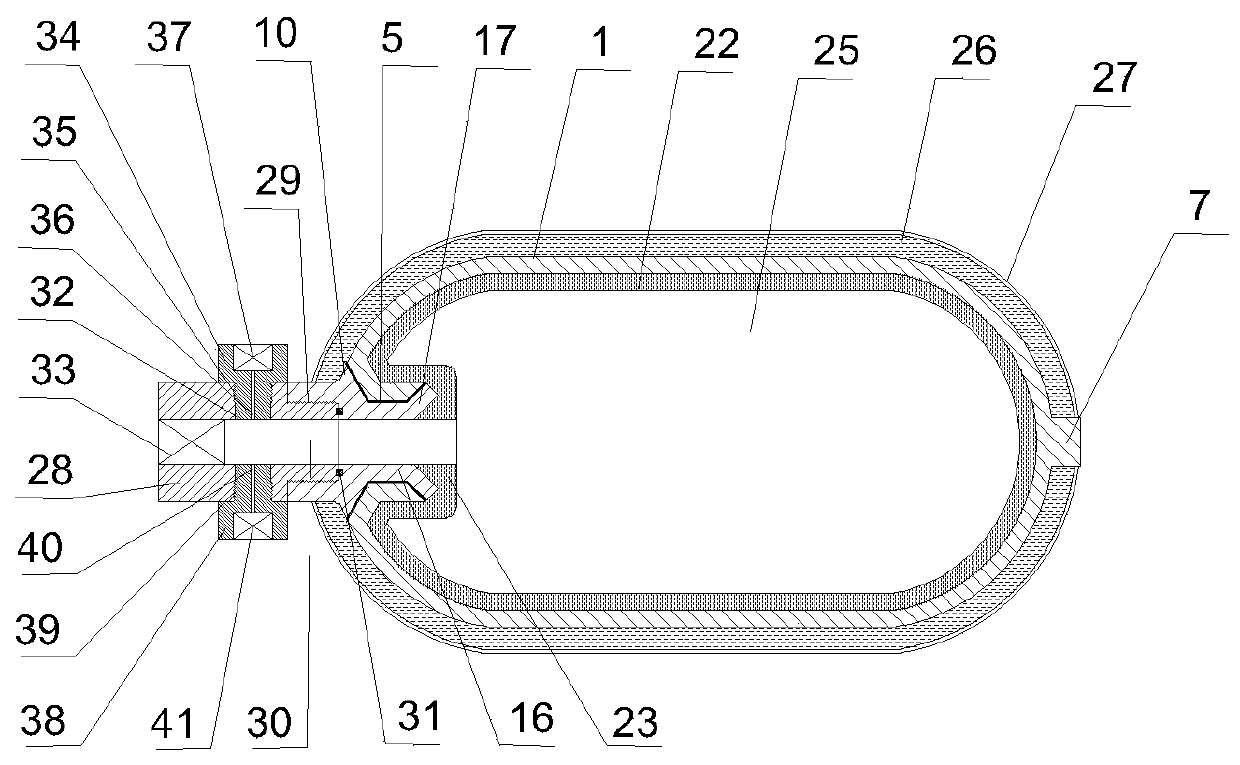

[0039] The cross-sectional structure of the alloy gas storage cylinder with the shape memory alloy valve is shown in the figure figure 1 as shown, figure 2 yes figure 1 The cross-sectional structure diagram of the inner resin bottle made of the alloy gas storage bottle, image 3 yes figure 2Schematic diagram of the cross-sectional structure of the carbon fiber alloy gas storage cylinder coated with silicone resin glue, in which: 1 is the alloy hydrogen storage bottle, 2 is the thickened straight wall of the alloy hydrogen storage bottle, 3 is the arc-shaped wall of the alloy hydrogen storage bottle mouth, and 4 is the alloy hydrogen storage bottle The arc-shaped wall at the bottom of the hydrogen storage bottle, 5 is the mouth of the hydrogen storage bottle, 6 is the slope of the bottle mouth, 7 is the bottom column of the bottle, 8 is the inner cavity of the alloy hydrogen storage bottle, 9 is the valve of the shape memory alloy hydrogen storage bottle, and 10 is the valv...

Embodiment 2

[0044] The cross-sectional structure of an alloy gas storage cylinder with a shape memory alloy valve at one end and a shape memory alloy plug at the other end is shown in Figure 4 as shown, Figure 5 Yes Figure 4 One end is equipped with a shape memory alloy valve and the other end is equipped with a shape memory alloy sealing alloy gas storage cylinder to make a cross-sectional structure diagram of the inner resin bottle, Image 6 Yes Figure 5 One end is equipped with a shape memory alloy valve, and the other end is equipped with a shape memory alloy sealing outer winding coated with silicone resin glue carbon fiber alloy gas storage cylinder sectional structure schematic diagram, wherein: 42 is an alloy gas storage cylinder, 43 is a bottle mouth, 44 is a bottle mouth slope, 45 is the bottom opening of the bottle, 46 is the slope of the bottom opening of the bottle, 47 is the cavity of the alloy gas storage cylinder, 48 is the shape memory alloy valve, 49 is the incline...

Embodiment 3

[0050] The cross-sectional structure of an alloy gas storage cylinder with shape memory alloy valves installed at both ends is shown in Figure 7 as shown, Figure 8 Yes Figure 7 The cross-sectional structure diagram of the inner resin bottle made of an alloy gas storage bottle equipped with shape memory alloy valves at both ends, Figure 9 Yes Figure 8Schematic diagram of the cross-sectional structure of an outer wound carbon fiber alloy gas storage cylinder with shape memory alloy valves installed at both ends, in which: 86 is the alloy gas storage cylinder, 87 is the valve bottle mouth, 88 is the slope of the valve bottle mouth, and 89 is the bottom valve bottle 90 is the bevel of the bottle mouth of the bottom valve, 91 is the cavity of the alloy gas cylinder, 92 is the shape memory alloy valve, 93 is the inclined shoulder of the shape memory alloy, 94 is the connection port of the shape memory alloy valve, and 95 is inside the shape memory alloy valve port Thread, 96...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap