Debugging and calibrating device for mechanical sphygmomanometer

A technology for calibration devices and blood pressure meters, which is applied in the direction of measuring devices, applications, blood vessel evaluation, etc., can solve the problems of no breakthrough in blood pressure meter debugging and calibration, high cost of debugging and calibration, and low efficiency of debugging and calibration, so as to improve work quality and work efficiency , Reduce work intensity, improve the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

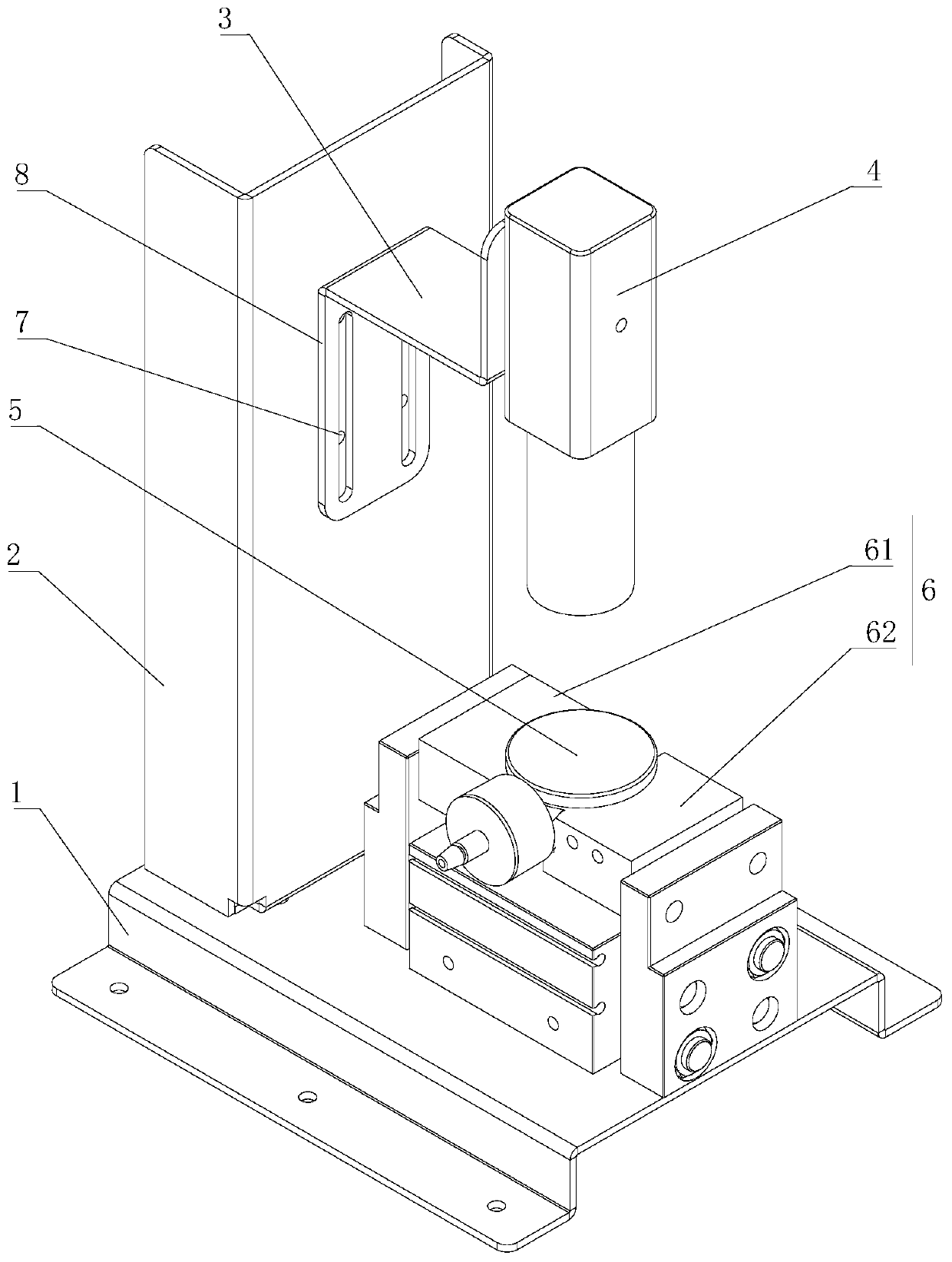

[0018] refer to figure 1 , a debugging and calibrating device for mechanical sphygmomanometers proposed by the present invention, comprising: a host computer, a laser printer, a controller, a connecting pipe, a plurality of pressure sources, a start button for starting the controller, a base 1 and a camera 4;

[0019] A tooling fixture 6 and a support frame 2 for clamping the blood pressure gauge 5 are arranged on the base 1, the camera 4 is installed on the support frame 2, and the camera of the camera 4 faces the dial of the blood pressure gauge 5;

[0020] The connecting pipe includes an outlet pipe end and a plurality of inlet pipe ends, the outlet pipe end is used to communicate with the sphygmomanometer 5, and the plurality of inlet pipe ends communicate with a plurality of pressure sources one by one, and each inlet pipe end is provided with The electromagnetic valve;

[0021] The controller controls and connects a plurality of electromagnetic valves and cameras 4 res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com