Food processor with long service life

A technology for food processing machines and bases, applied in applications, kitchen utensils, home utensils, etc., can solve the problems of shortening the durability and service life of the feeding cover, affecting the normal use and loosening of the feeding cover, and improving the user experience and satisfaction. degree, noise reduction, noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

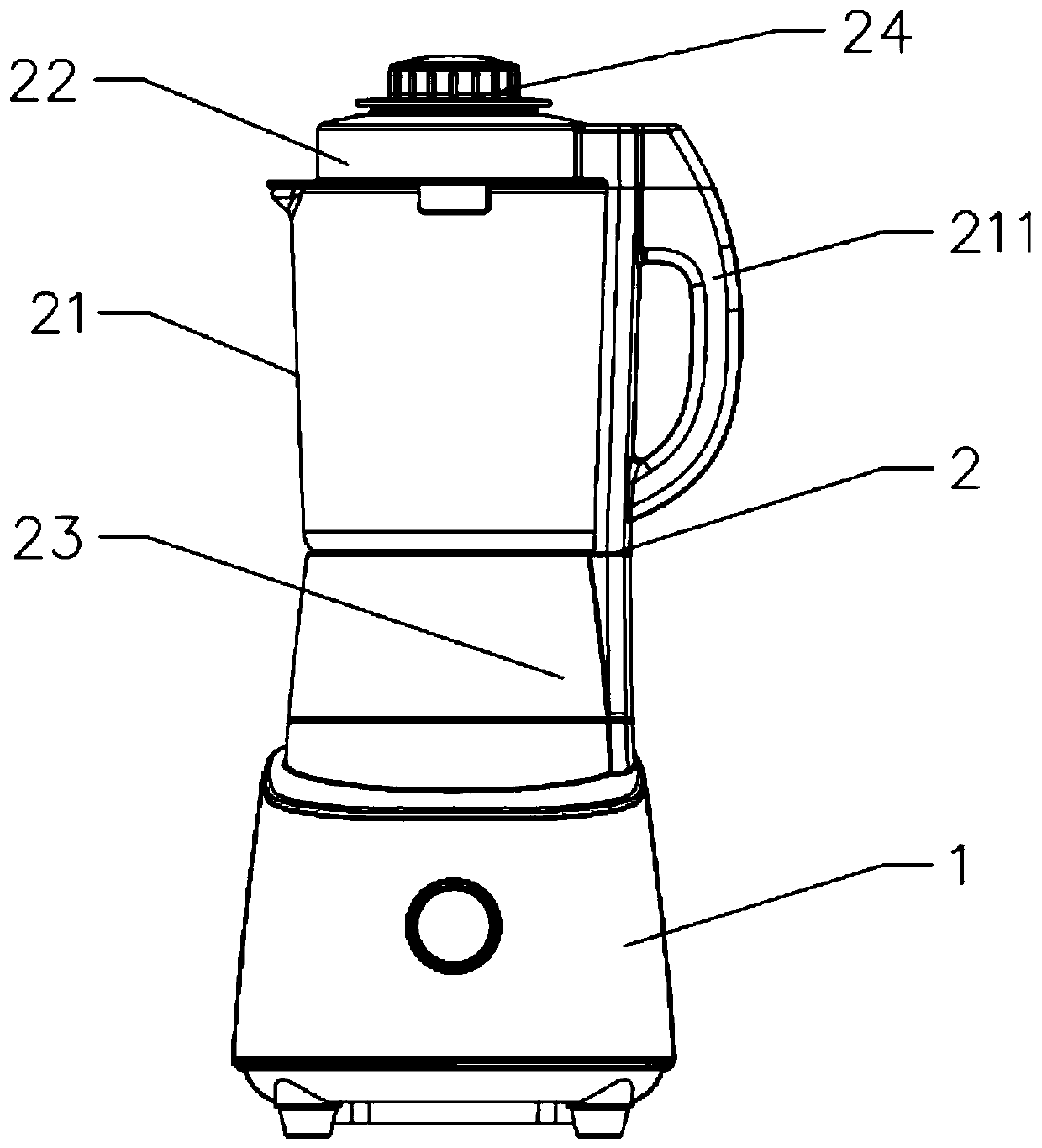

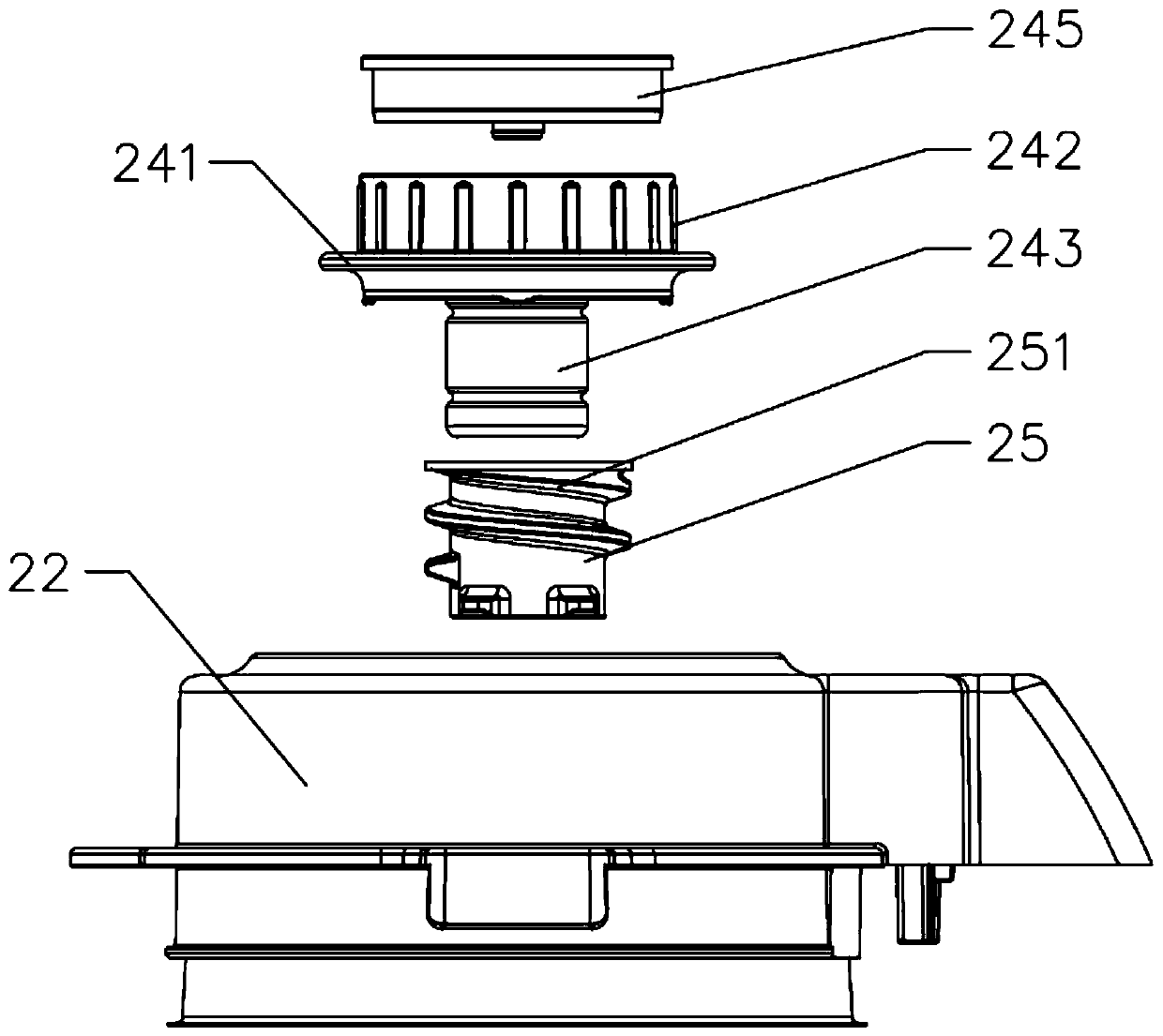

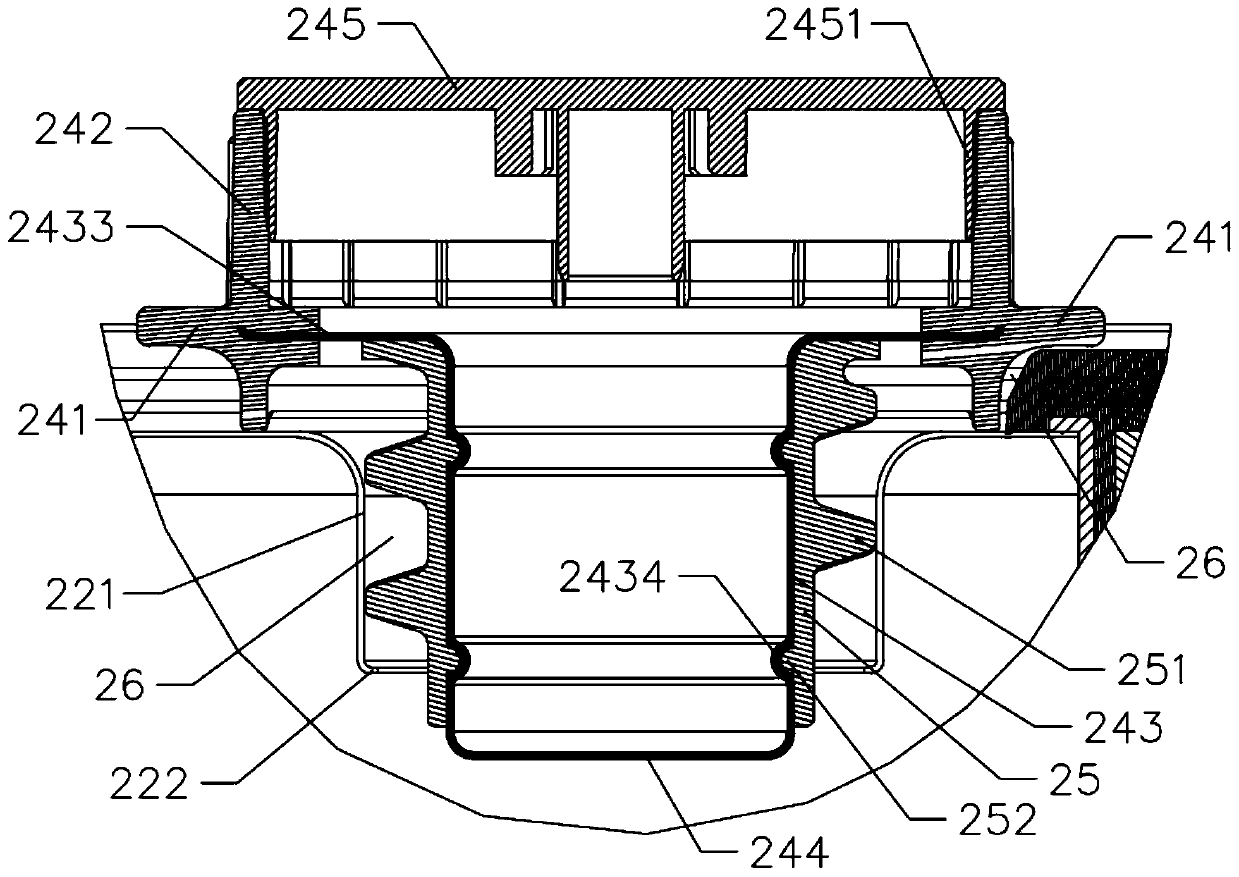

[0045] Such as Figures 1 to 10 As shown, the present invention provides a food processor with a long service life, including a machine base 1 and a stirring cup 2, a motor (not shown in the figure) and a control panel (not shown in the figure) are arranged in the machine base 1, The stirring cup 2 includes a cup body 21 and a cup cover 23 covering the top of the cup body 21. The side wall of the cup body 21 is provided with a handle 211, and a cup holder 23 is provided below the cup body 21. The stirring cup 2 is detachably installed through the cup holder 23. Above the machine base 1, a feeding channel 221 is provided on the cup cover 22, and a feeding cover 24 is provided at the feeding channel 221. The feeding cover 24 includes a baffle 241, a gripping portion 242 positioned at the upper end of the baffle 241 and a lower end of the baffle 241. and extend into the insertion part 243 in the feeding channel 221.

[0046] In this embodiment, the insertion portion 243 is seale...

Embodiment 2

[0063]The difference between this embodiment and the first embodiment lies in that the setting positions of the sealing plates are different.

[0064] In this example, if Figures 11 to 12 As shown, the sealing plate 244 is set at the upper port 2431, so that the insertion part 243 is closed, and the upper surface of the sealing plate 244 is not set higher than the upper port 2431 of the insertion part 243. The connection between the plates is fixed, and it can well prevent the gas from entering the joint between the insertion part and the baffle, so as to avoid loosening between the insertion part and the baffle, so as to ensure the normal use of the feeding cover.

[0065] The structures and beneficial effects of other parts not described are the same as those in Embodiment 1, and will not be repeated here.

Embodiment 3

[0067] The difference between this embodiment and the first embodiment lies in that the setting positions of the sealing plates are different.

[0068] In this example, if Figures 13 to 14 As shown, the sealing plate 244 is arranged in the insertion portion 243, the sealing plate 244 is located between the upper port 2431 and the lower port 2432, so that the insertion portion 243 is closed, and the sealing plate 244 is specifically located in the middle of the upper port 2431 and the lower port 2432 Position, so that although the gas can enter the insertion part, it will be blocked by the sealing plate and will not rise further to the upper port. This can also prevent the gas from entering the connection between the insertion part and the baffle and prevent the two from falling off.

[0069] The structures and beneficial effects of other parts not described are the same as those in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com