Filtering separating device for bioengineering

A filtration separation and bioengineering technology, applied in separation methods, precipitation separation, grain processing, etc., can solve the problems of impure extraction of biological samples, affecting the accuracy of experimental results, and residual biological samples.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

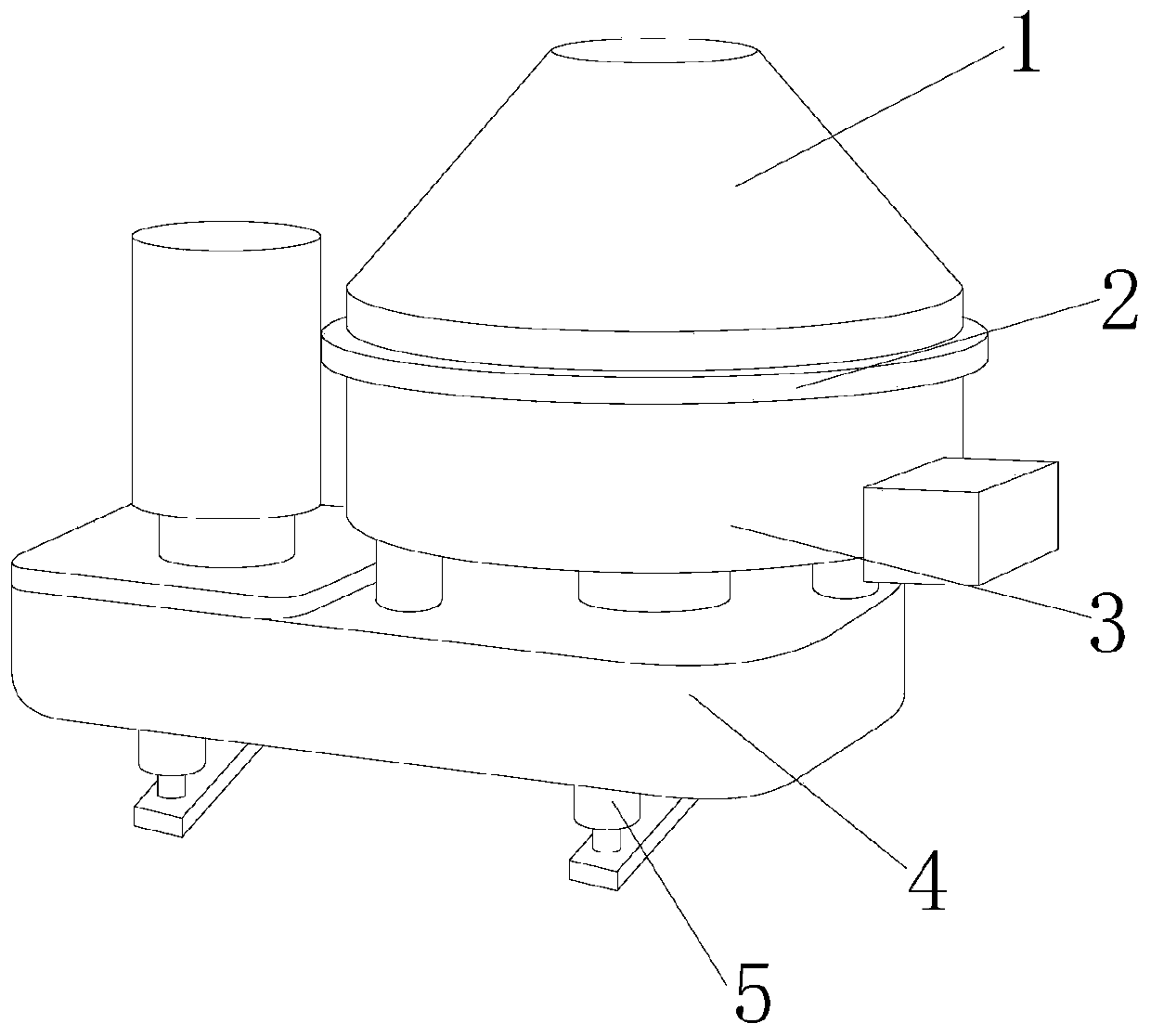

[0029] see Figure 1-Figure 7 , the present invention provides a filtration and separation device for bioengineering, the structure of which includes a separation chamber 1, a connecting ring 2, an inactivation device 3, a fixing seat 4, and a supporting foot 5, and the separation chamber 1 is installed on the fixing seat 4, so that The bottom of the fixed seat 4 is provided with a supporting foot 5, and the supporting foot 5 is provided with two, and is set up in a symmetrical structure. Inside, the connecting ring 2 is set up in a concentric ring shape, and the connecting ring 2 is mechanically connected to the outer wall of the separation chamber 1;

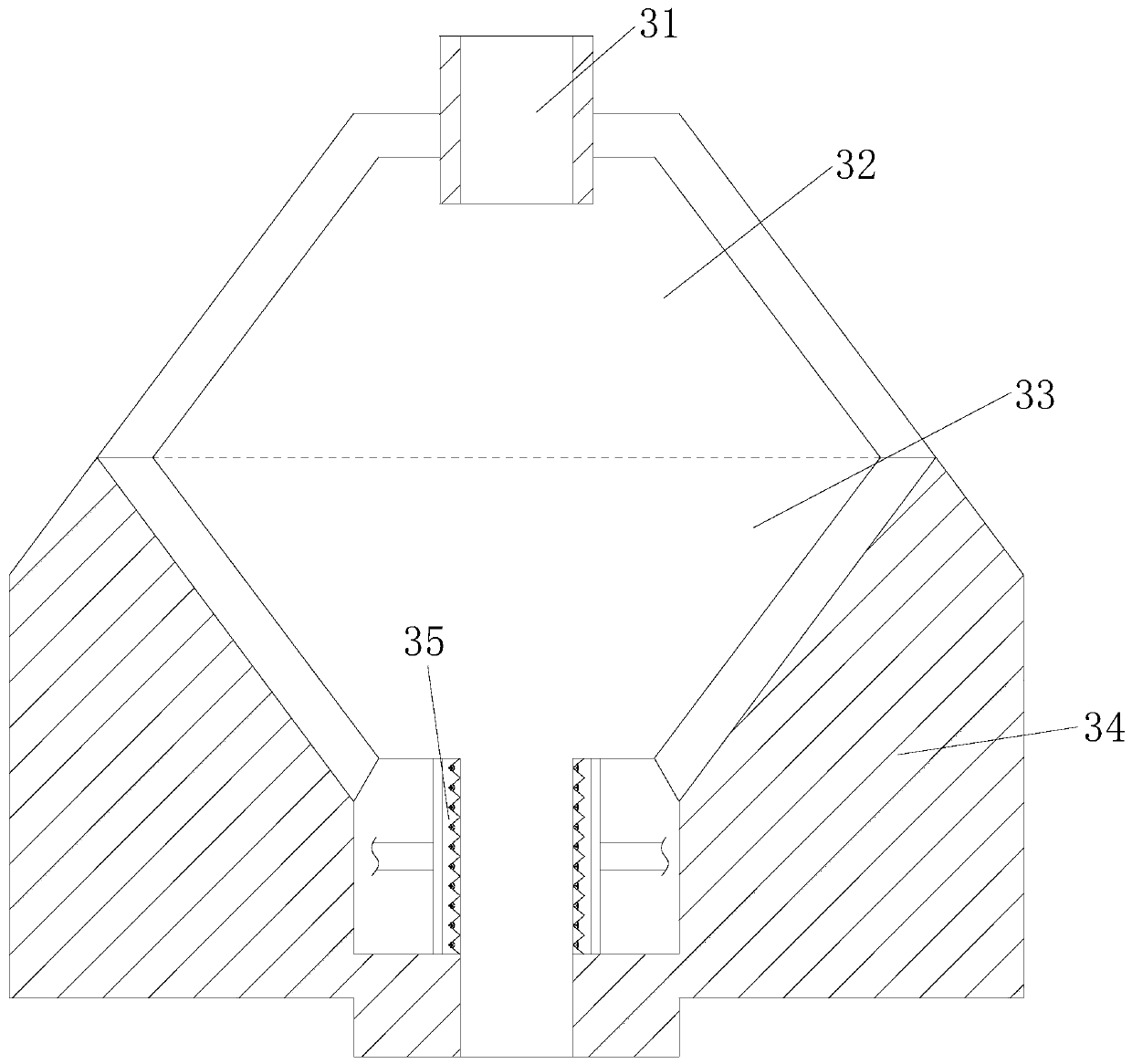

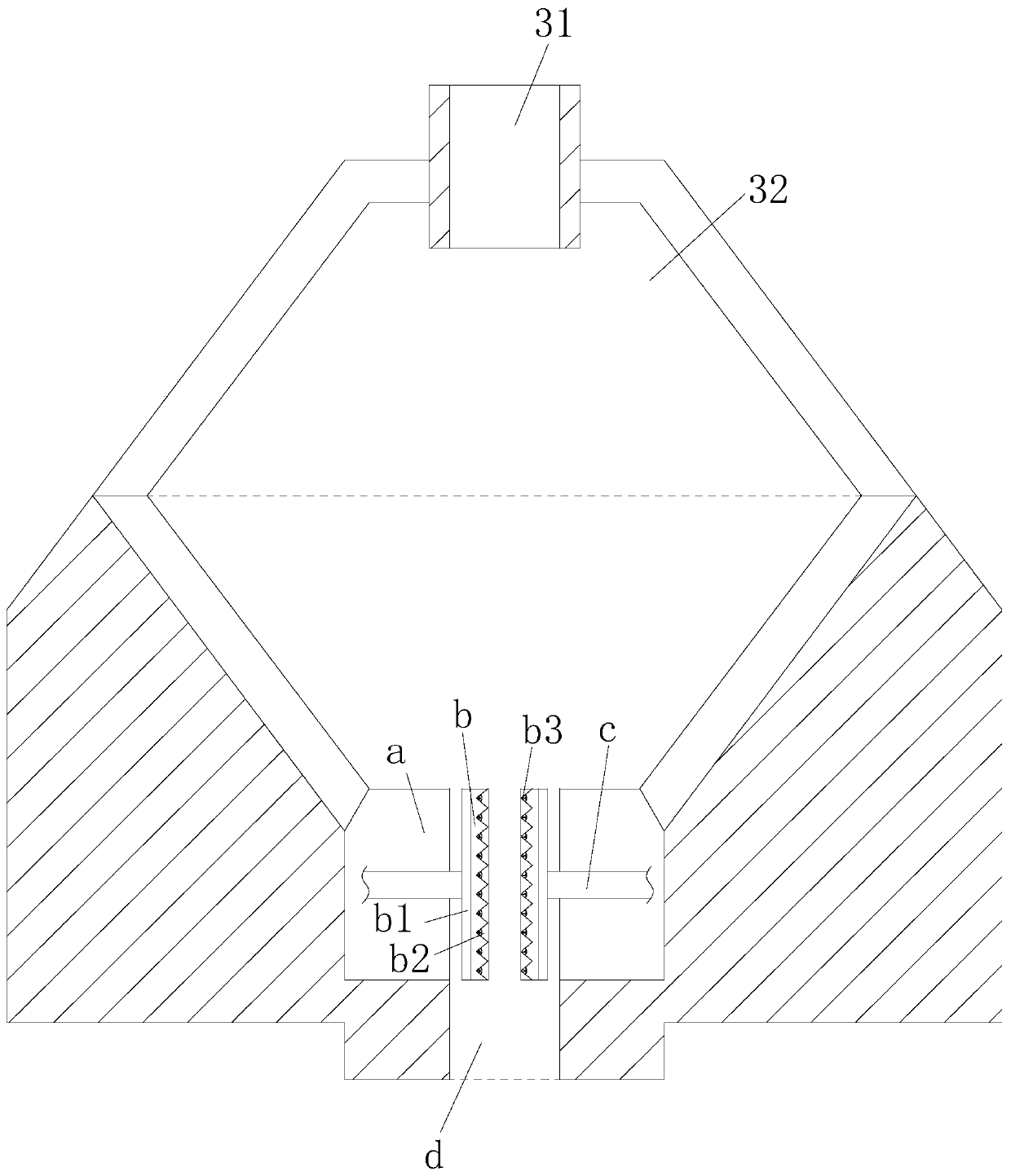

[0030] Described inactivation device 3 is made of upper outlet 31, upper chamber 32, lower chamber 33, wall layer 34, lower outlet 35, and described upper outlet 31 is connected with upper chamber 32, and between described upper chamber 32, lower chamber 33 The upper chamber 32 and the lower chamber 33 have the same structure...

Embodiment 2

[0041] see Figure 1-Figure 4 , Figure 7 , the present invention provides a filtration and separation device for bioengineering, the structure of which includes a separation chamber 1, a connecting ring 2, an inactivation device 3, a fixing seat 4, and a supporting foot 5, and the separation chamber 1 is installed on the fixing seat 4, so that The bottom of the fixed seat 4 is provided with a supporting foot 5, and the supporting foot 5 is provided with two, and is set up in a symmetrical structure. Inside, the connecting ring 2 is set up in the shape of a concentric ring, and the connecting ring 2 is mechanically connected to the outer wall of the separation chamber 1; The lower outlet 35 is formed, the upper outlet 31 is connected with the upper cavity 32, and the upper cavity 32 and the lower cavity 33 are connected. The upper cavity 32 and the lower cavity 33 have the same structure and are relatively set up in an up and down structure. The lower chamber 33 communicates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com