Clamping jaw with composite structure on surface

A composite structure and gripper technology, applied in the field of robot end effector devices, can solve the problems of low stability, easy damage to objects, and difficulty in effectively grasping products of various shapes and types, and achieves convenient operation and effective grasping. , compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

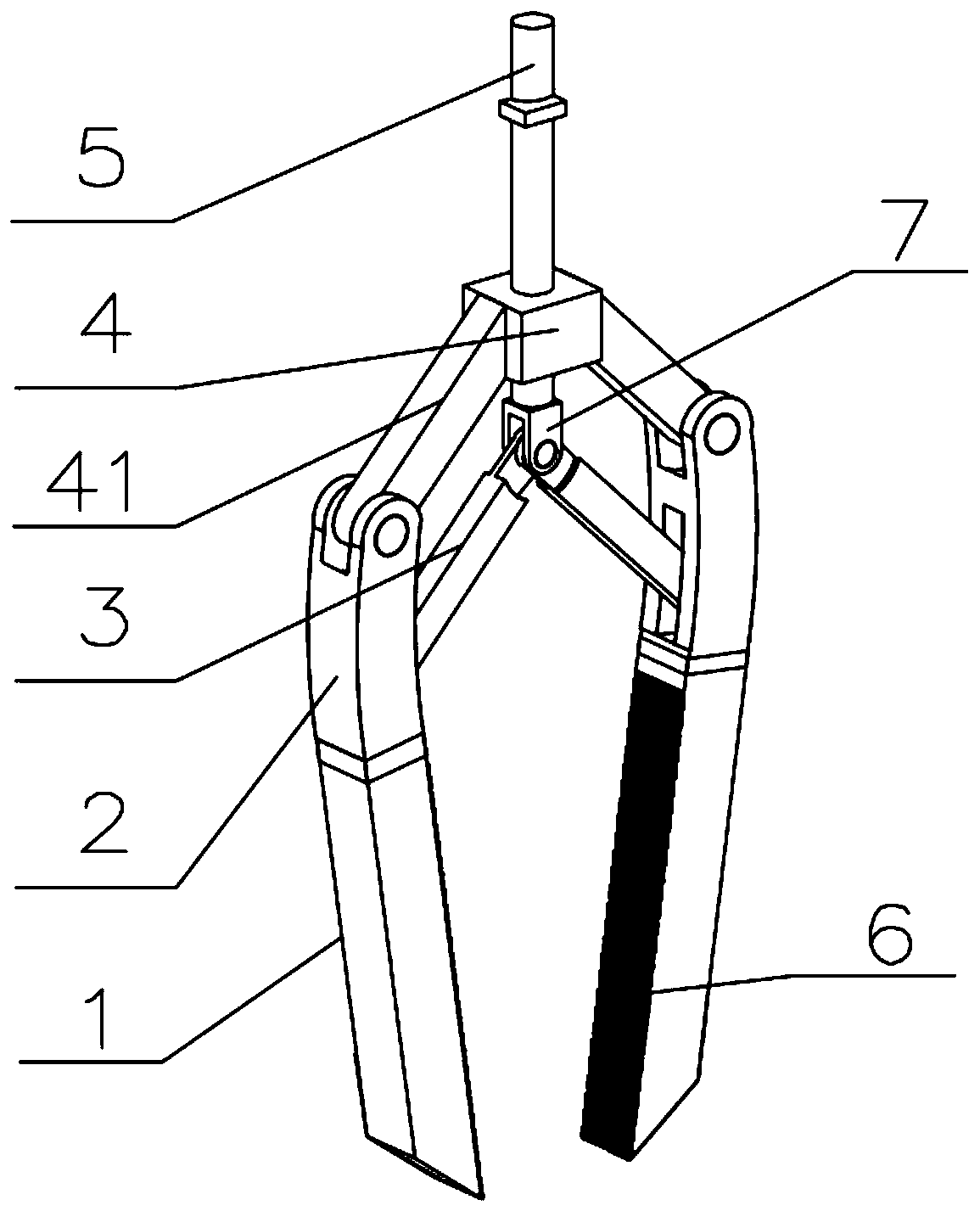

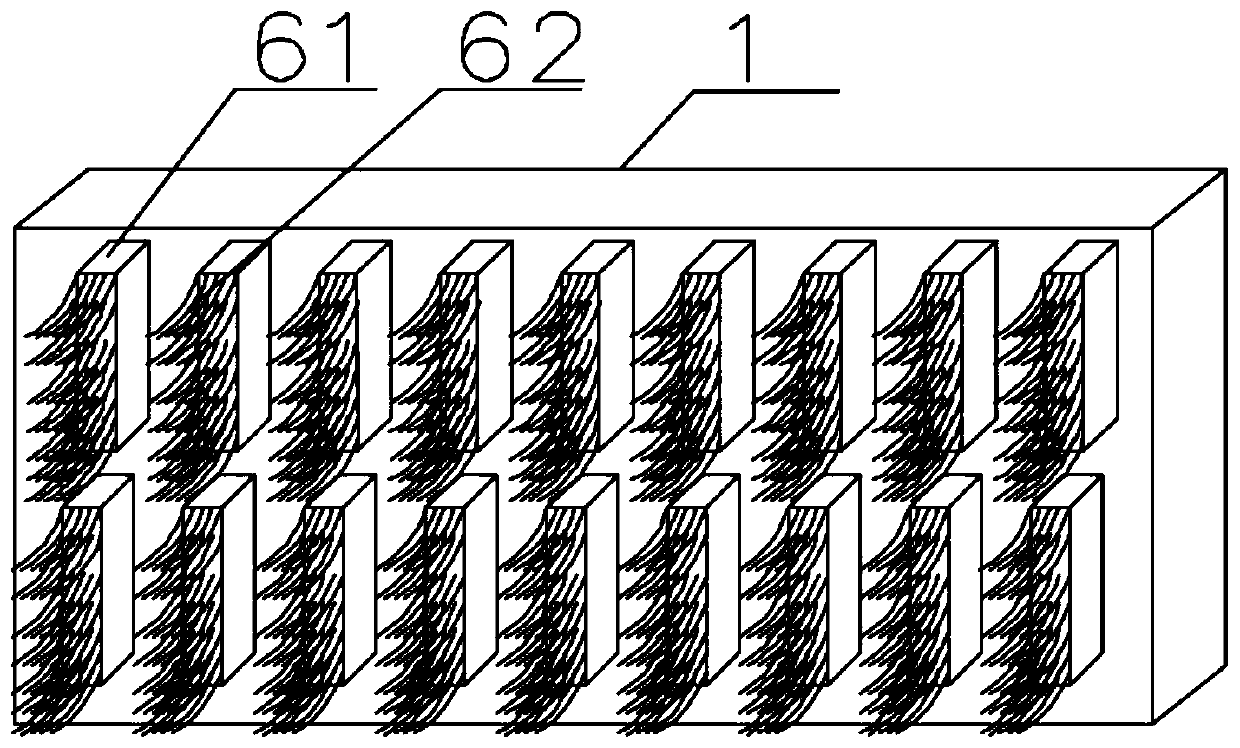

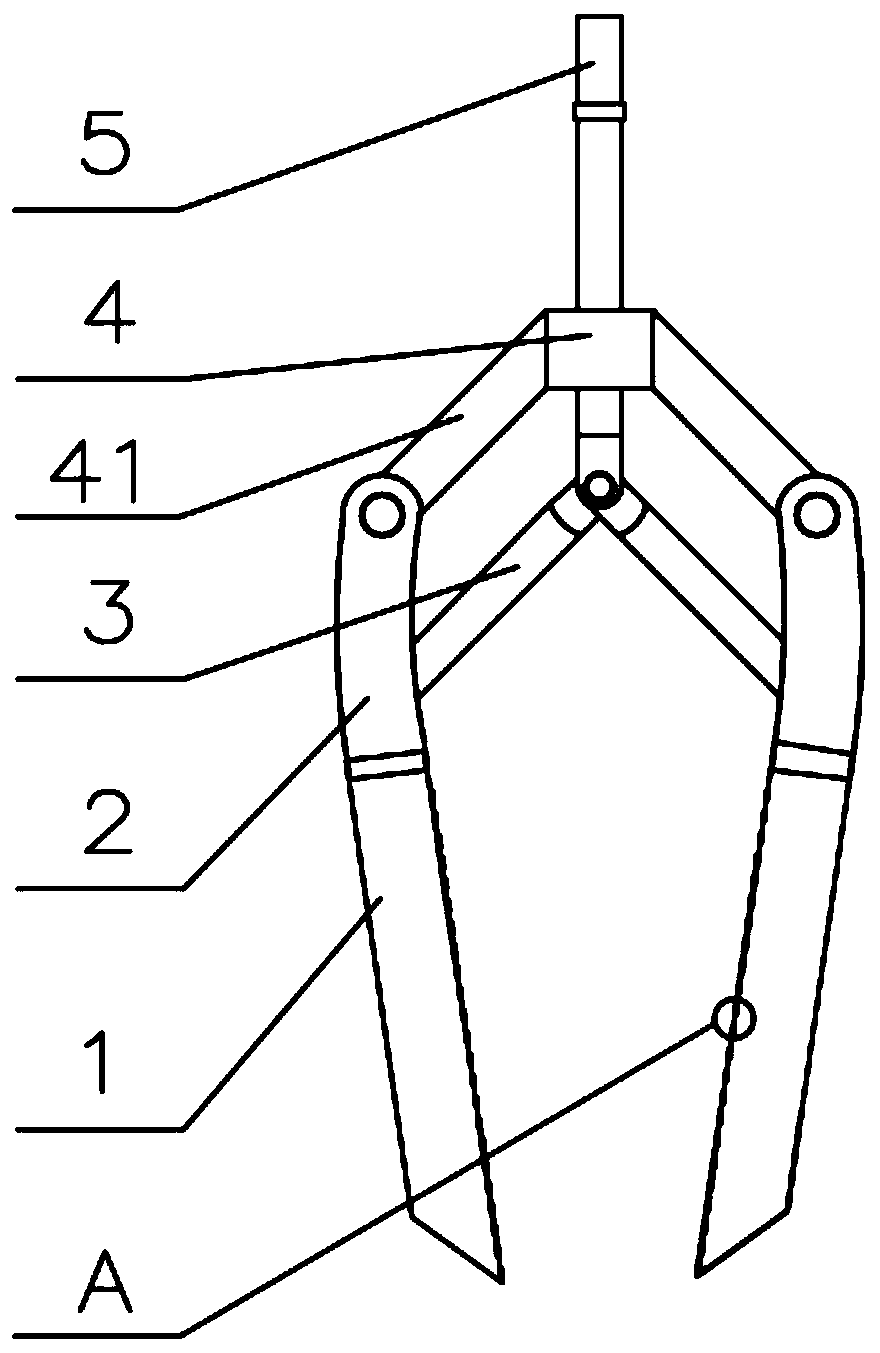

[0023] like Figure 1-Figure 4 As shown, the surface of this embodiment has a gripper with a composite structure, including two relatively moving clamping plates 1, and the two clamping plates 1 are driven by the drive mechanism to perform synchronous relative motion to hold the grasped object tightly or Loosen, the surface of the clamping plate 1 is provided with a soft hair body structure 6, which includes a first soft hair portion 61 fixed on the surface of the clamping plate 1, and one end surface of the first soft hair portion 61 is provided with a number of closely arranged The second fur portion 62 , the second fur portion 62 is suspended above the surface of the clamping plate 1 .

[0024] The structure of the driving mechanism includes a piston rod 5, which is passed through the fixed bracket 4. The fixed bracket 4 has two symmet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com