Return track device

A track and return technology, applied in auxiliary molding equipment, ceramic molding machines, manufacturing tools, etc., can solve problems such as large gaps and affecting production efficiency, and achieve the effects of improving production efficiency, reducing safety hazards, and facilitating horizontal passage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

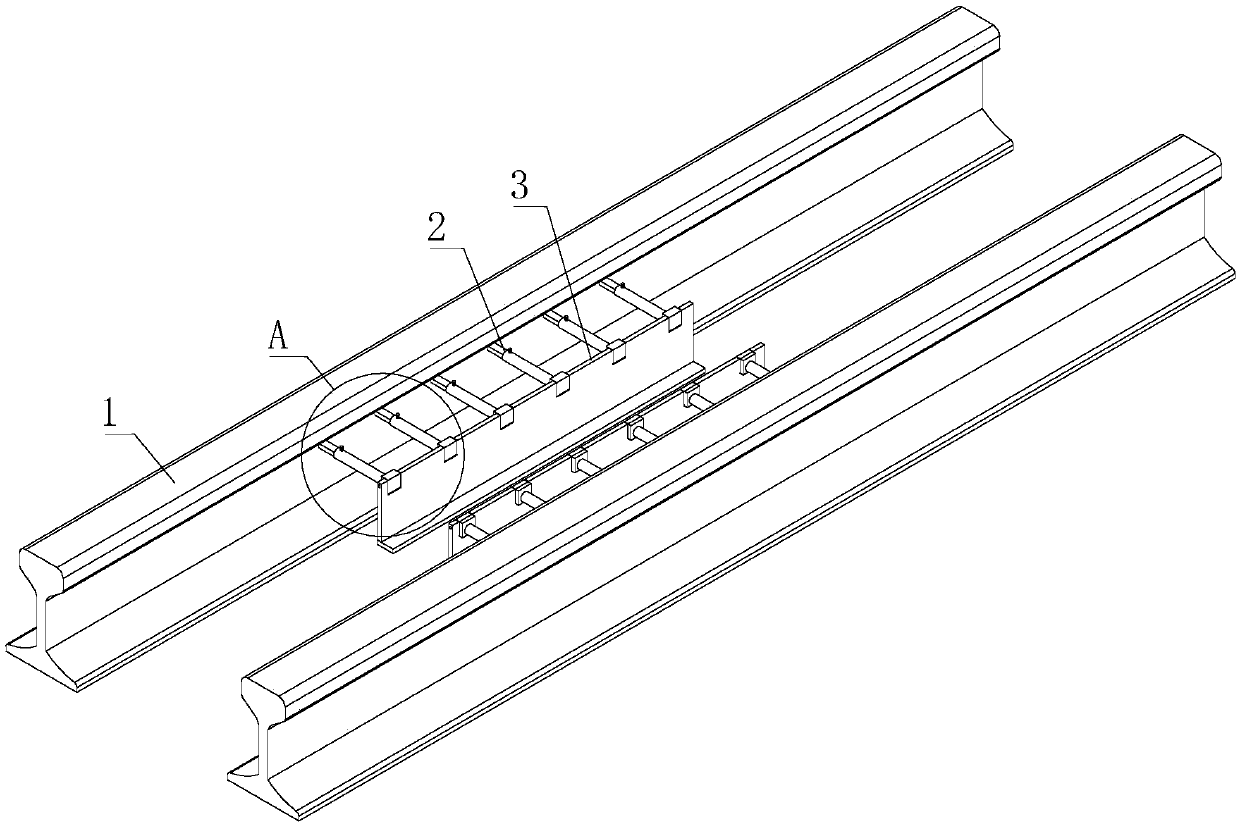

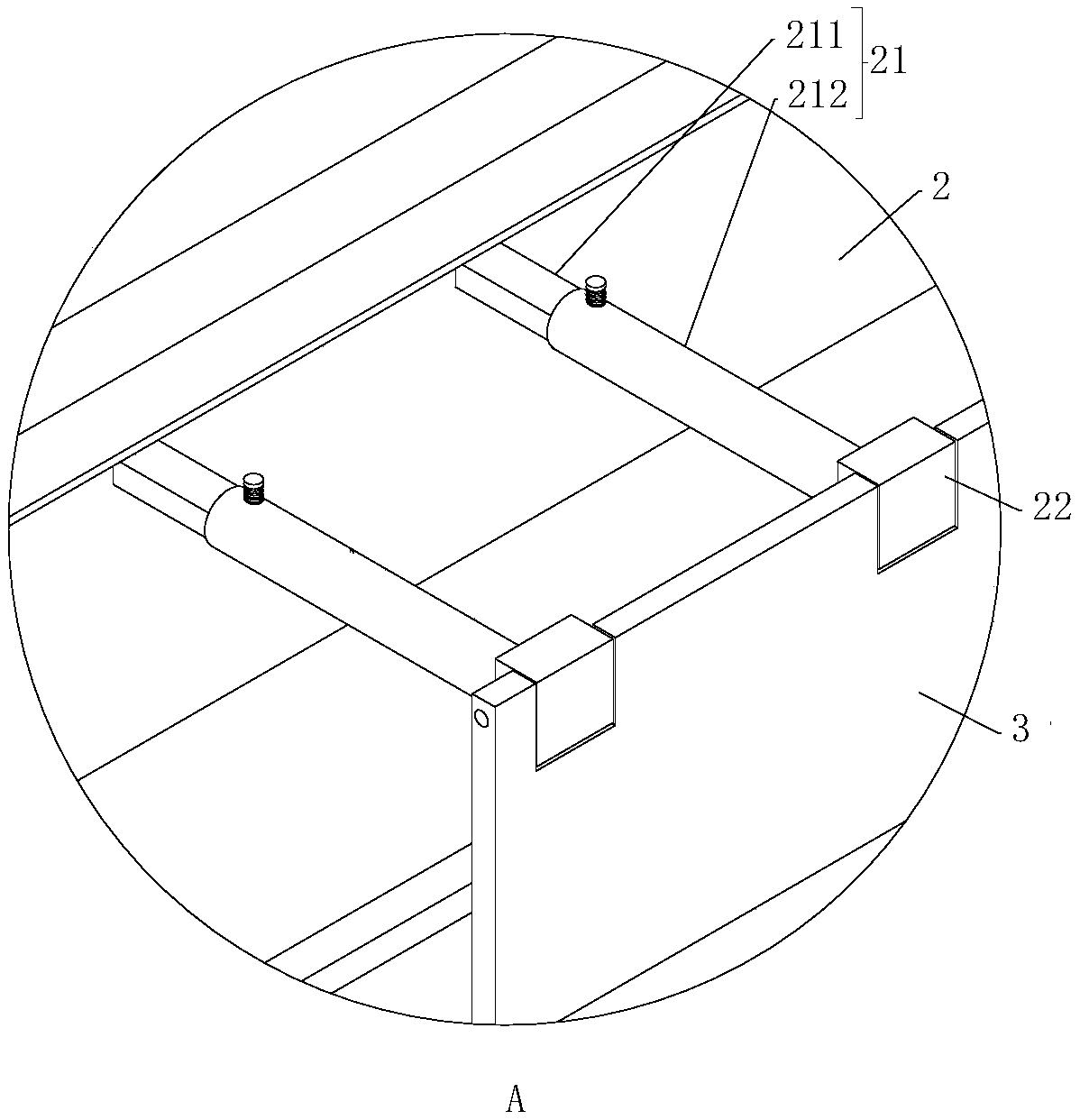

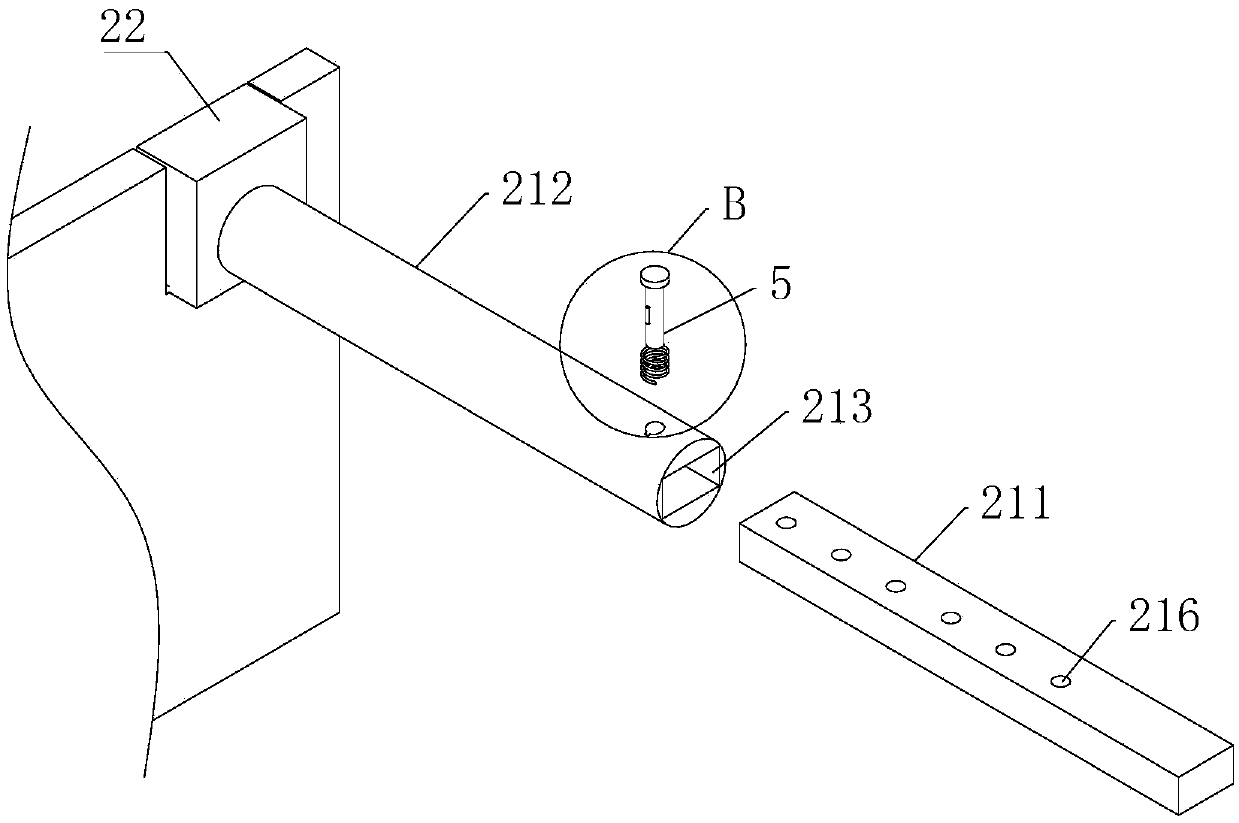

[0034] Embodiment: A kind of backhaul track device, such as figure 1 As shown, two steel rails 1 are included. Foundation 6 (see Figure 5 ) is provided with a groove (not shown in the figure), the rail 1 is laid in the groove (not shown in the figure), and the top surface of the rail 1 is at the same height as the ground of the foundation 6 . The side wall of each steel rail 1 is provided with a support 2 , and the support 2 is located between two steel rails 1 . An adjustment plate 3 is hinged on the support member 2, and the adjustment plate 3 hangs down under the action of gravity. The return track device also includes a supporting platform 4 between two steel rails 1 (see Figure 5 ), the lower side of the adjustment plate 3 is against the supporting platform 4 (see Figure 5 ), the supporting platform 4 is a stacked brick, which can be removed from the underside of the adjusting plate 3. When the steam curing car slides on the rail 1, the regulating plate 3 will not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com