Vibration reduction assembly with upward vibration constraint structure as well as air conditioner

A technology of vibration-damping components and vibration-damping pads, which is applied in the direction of pump components, variable-capacity pump components, machines/engines, etc., can solve problems such as poor vibration-damping effects, achieve high transportation reliability, avoid repeated friction damage, reduce The effect of amplitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below with reference to the drawings and specific embodiments, but it is not intended to limit the present invention.

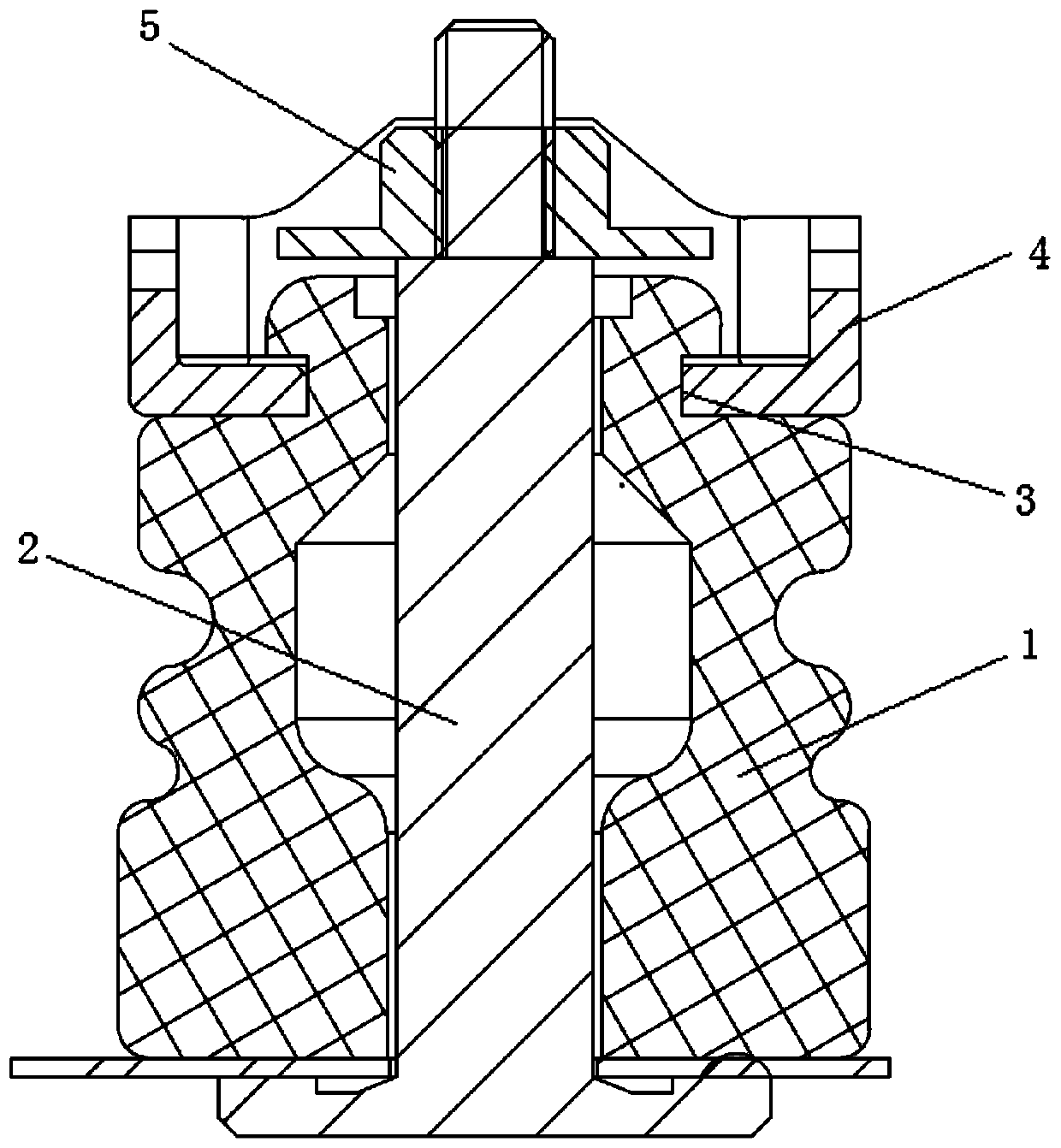

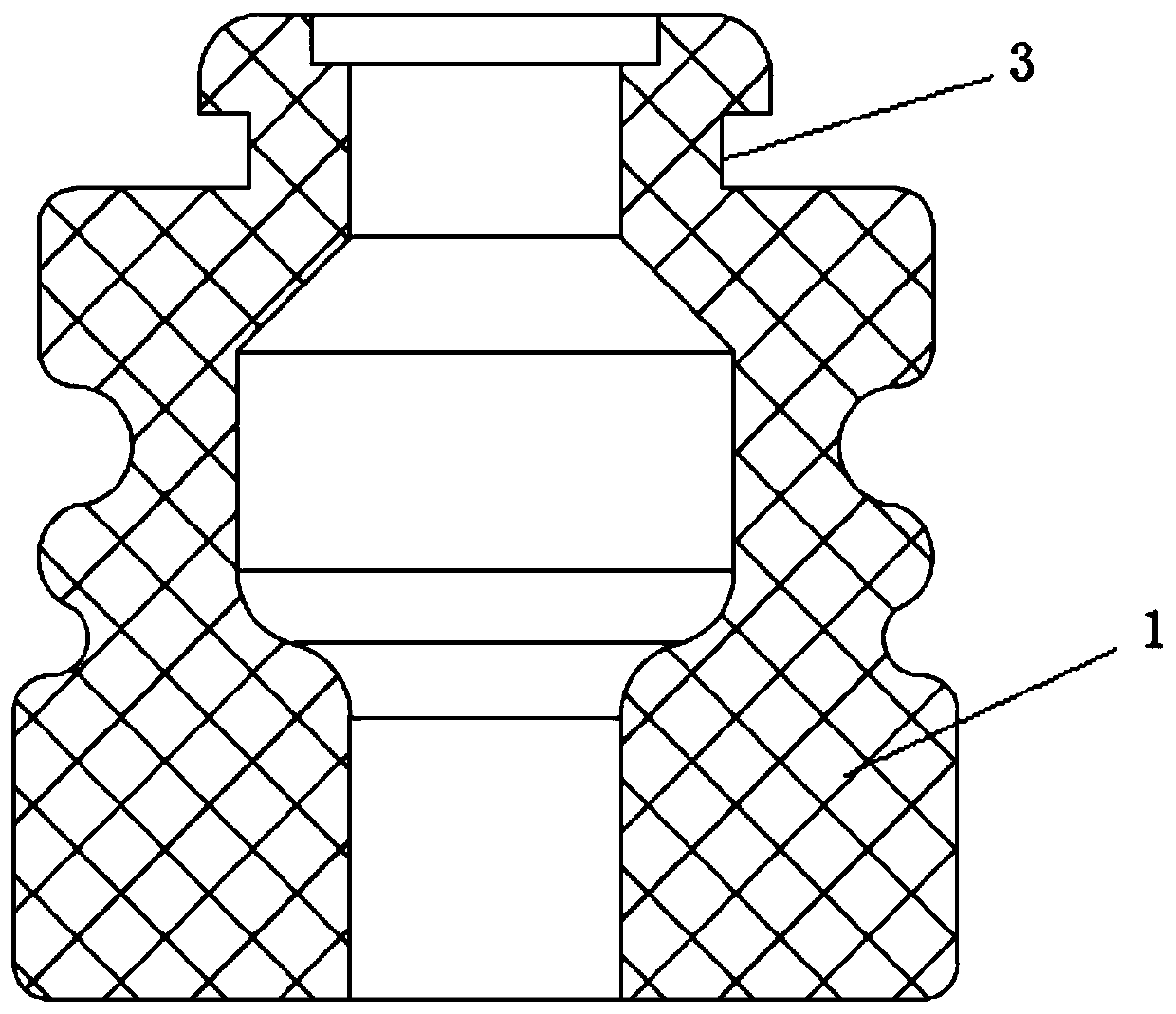

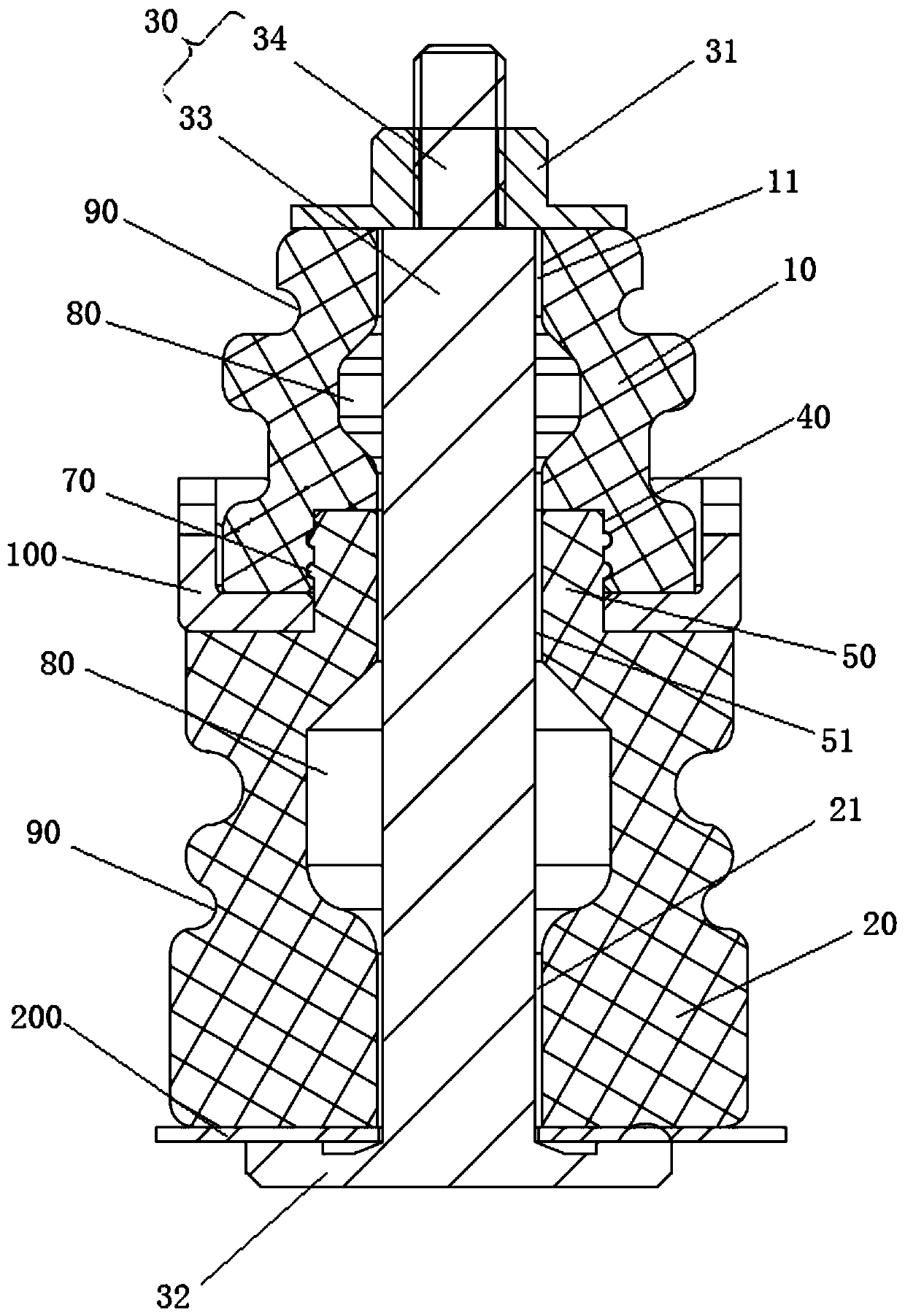

[0027] Such as Figure 3 to Figure 5 As shown, the vibration damping assembly with the upward vibration restraint structure of the first embodiment is used to mount the mounting plate 100 of the compressor on the chassis 200, thereby damping the compressor. The damping assembly includes an upper damping pad 10, a lower damping pad 20 and a positioning rod 30. Wherein, the lower end surface of the upper damping pad 10 and the upper end surface of the lower damping pad 20 jointly clamp the mounting plate 100 of the compressor. The upper damping pad 10 has a first through hole 11 penetrating in the axial direction, and the lower damping pad 20 has a second through hole 21 penetrating in the axial direction. The first through hole 11 corresponds to the second through hole 21. The positioning rod 30 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com