Bidirectional gas valve kit for sealed cabin of underwater robot and gas nozzle matched therewith

A technology of underwater robots and sealed cabins, applied in the field of sealed cabins, can solve the problems of being unable to pump negative pressure sealed cabins, lack of versatility, and easy sealing gaskets, etc., and achieve easy operation, simple and convenient operation, and easy replacement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

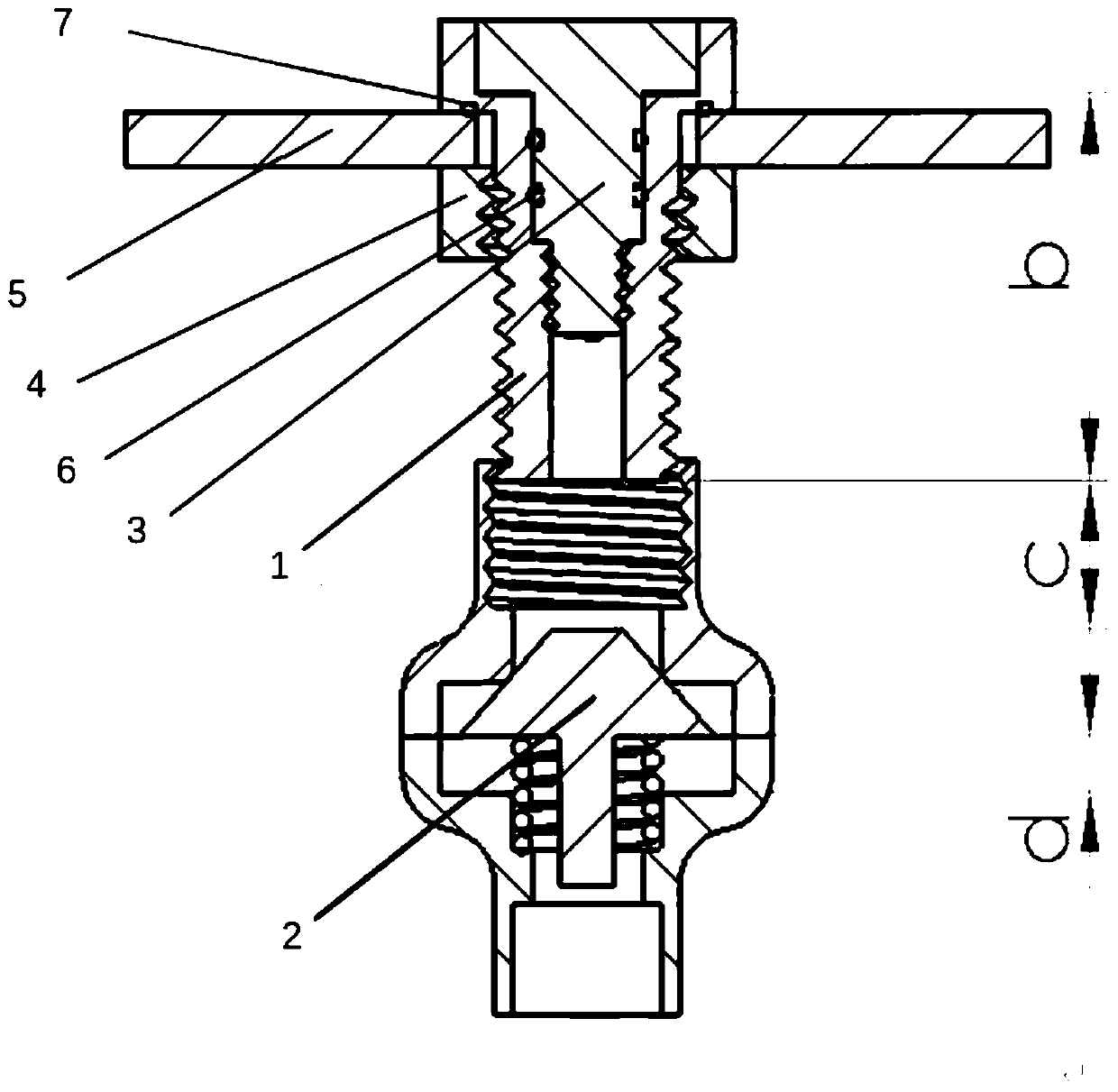

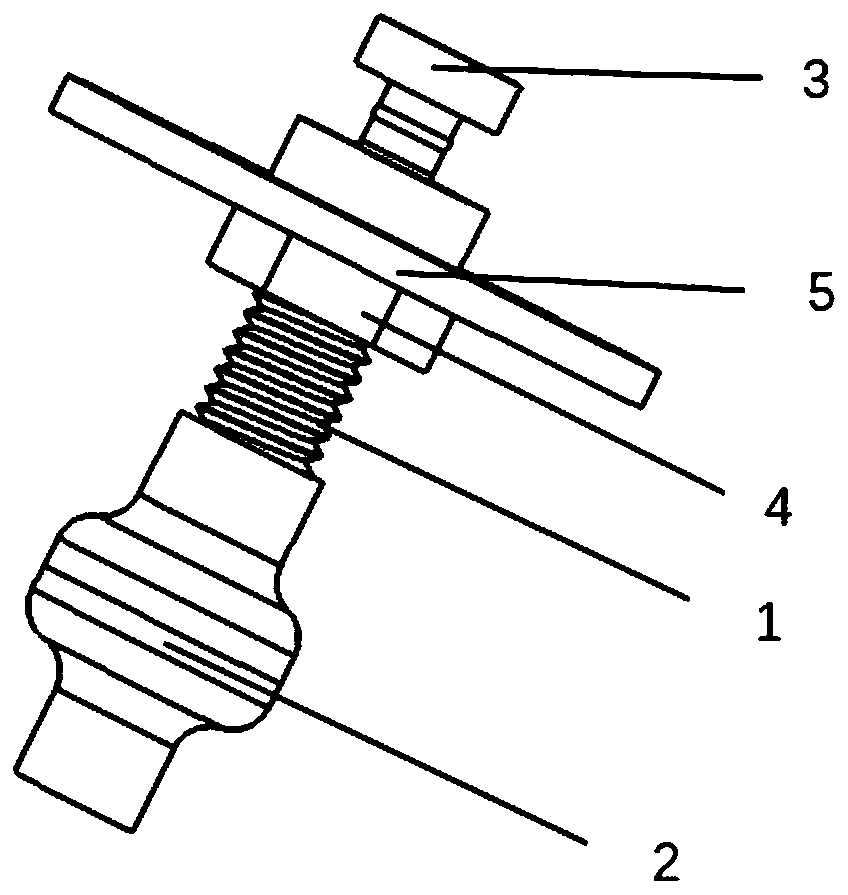

[0047] The present invention will be further described below in conjunction with the accompanying drawings. Such as Figure 1-10 As shown, a two-way air valve kit for a sealed cabin of an underwater robot includes a vent bolt A1, a vent bolt B2, a plug 3 and a nut 4.

[0048] The vent bolt A1 is installed on the airtight compartment hatch 5 through the nut 4, the upper end is located outside the airtight compartment hatch 5, and the lower end is located in the airtight compartment hatch 5, and the lower end of the vent bolt A1 and the vent bolt B2 are threaded Connection; the plug 3 is installed on the upper end of the vent bolt A1.

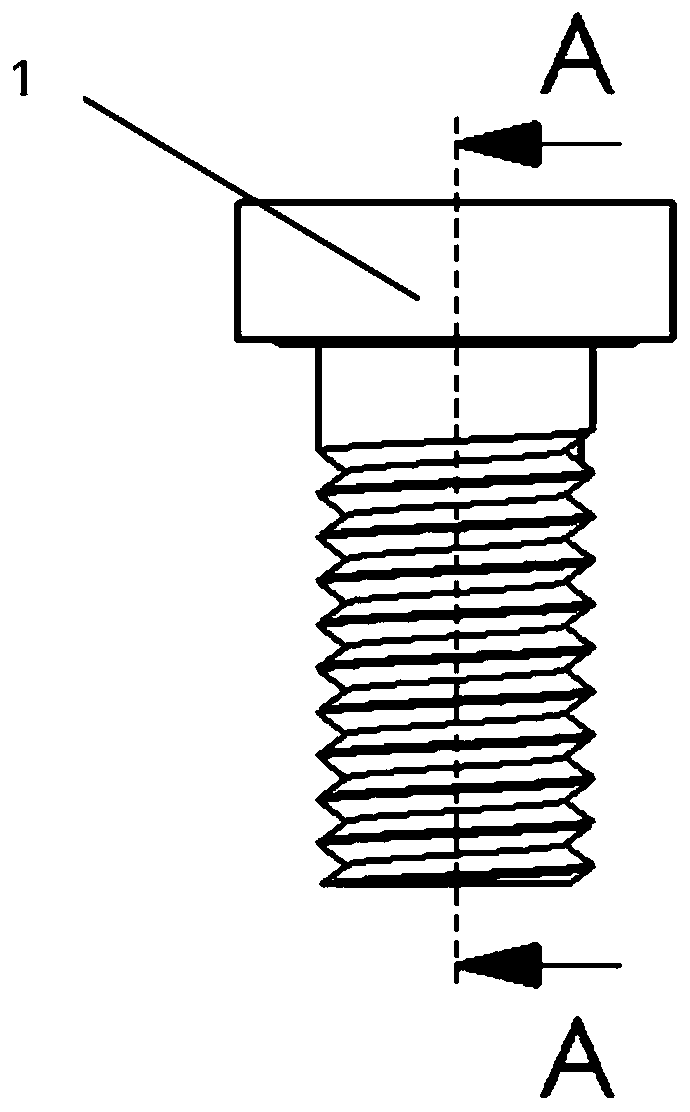

[0049]The ventilation bolt A1 is a hollow T-shaped bolt, and its internal structure is divided into three parts. The upper part is a plug with 3 holes, the middle part is an internal thread hole, and the lower part is a smooth round hole. The two sealing rings on the plug 3 are combined with the 3 holes at the upper end of the vent bolt A1 to f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com