Patents

Literature

37results about How to "Reduce pumping pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

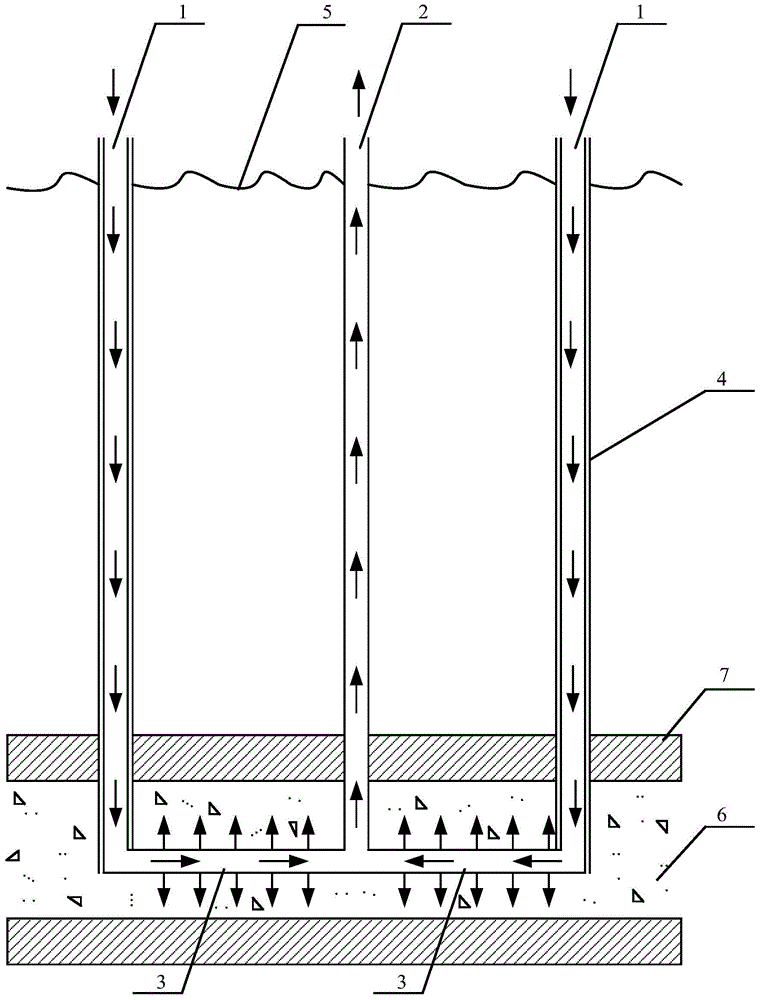

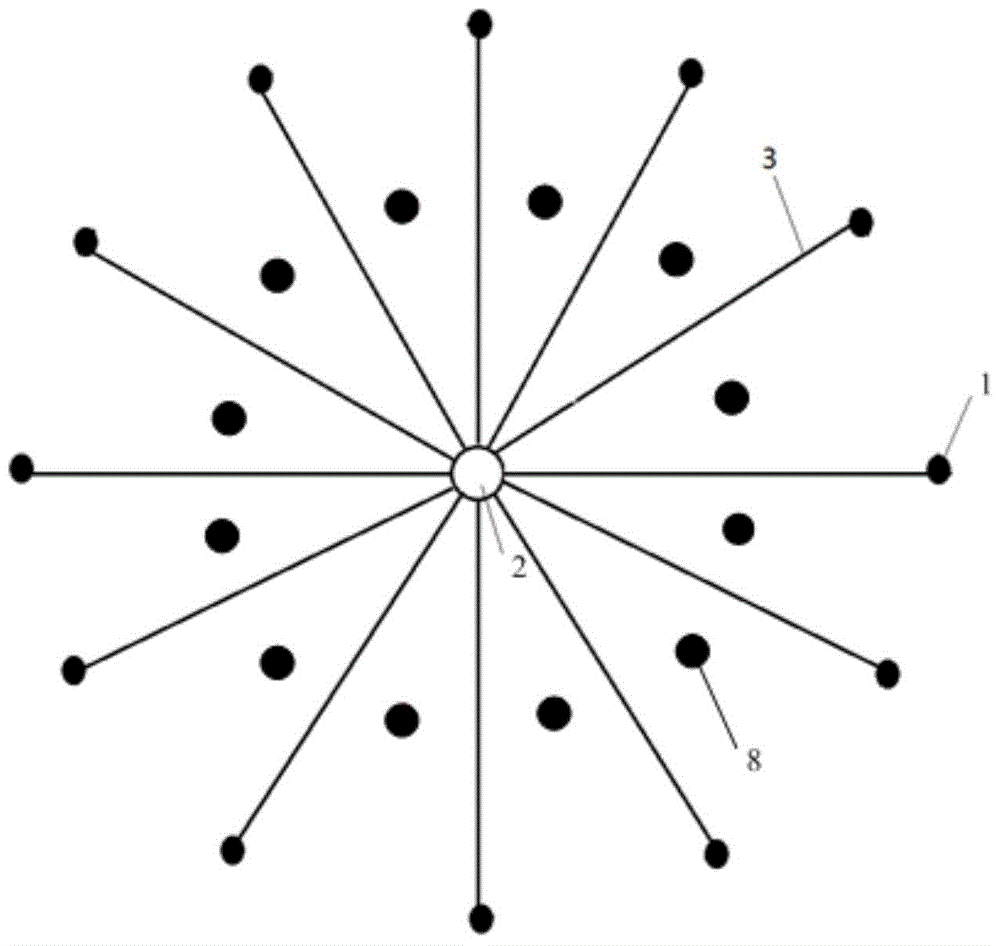

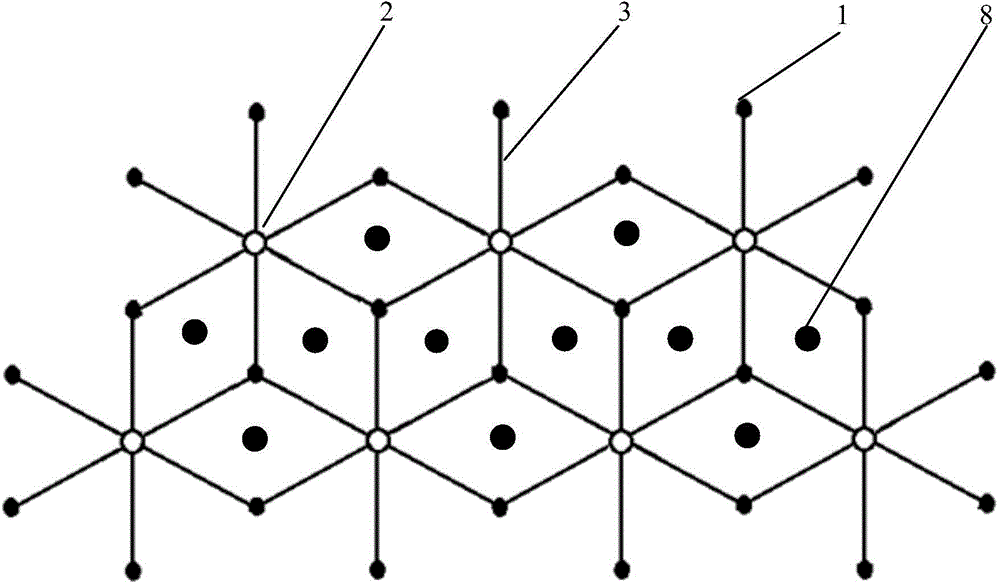

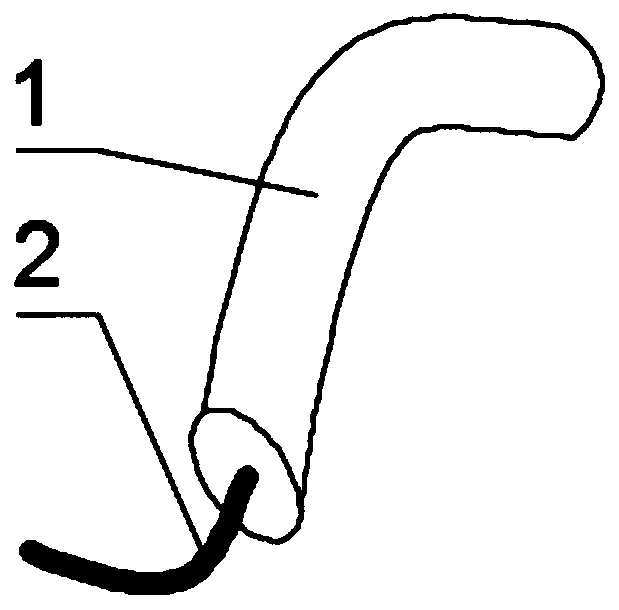

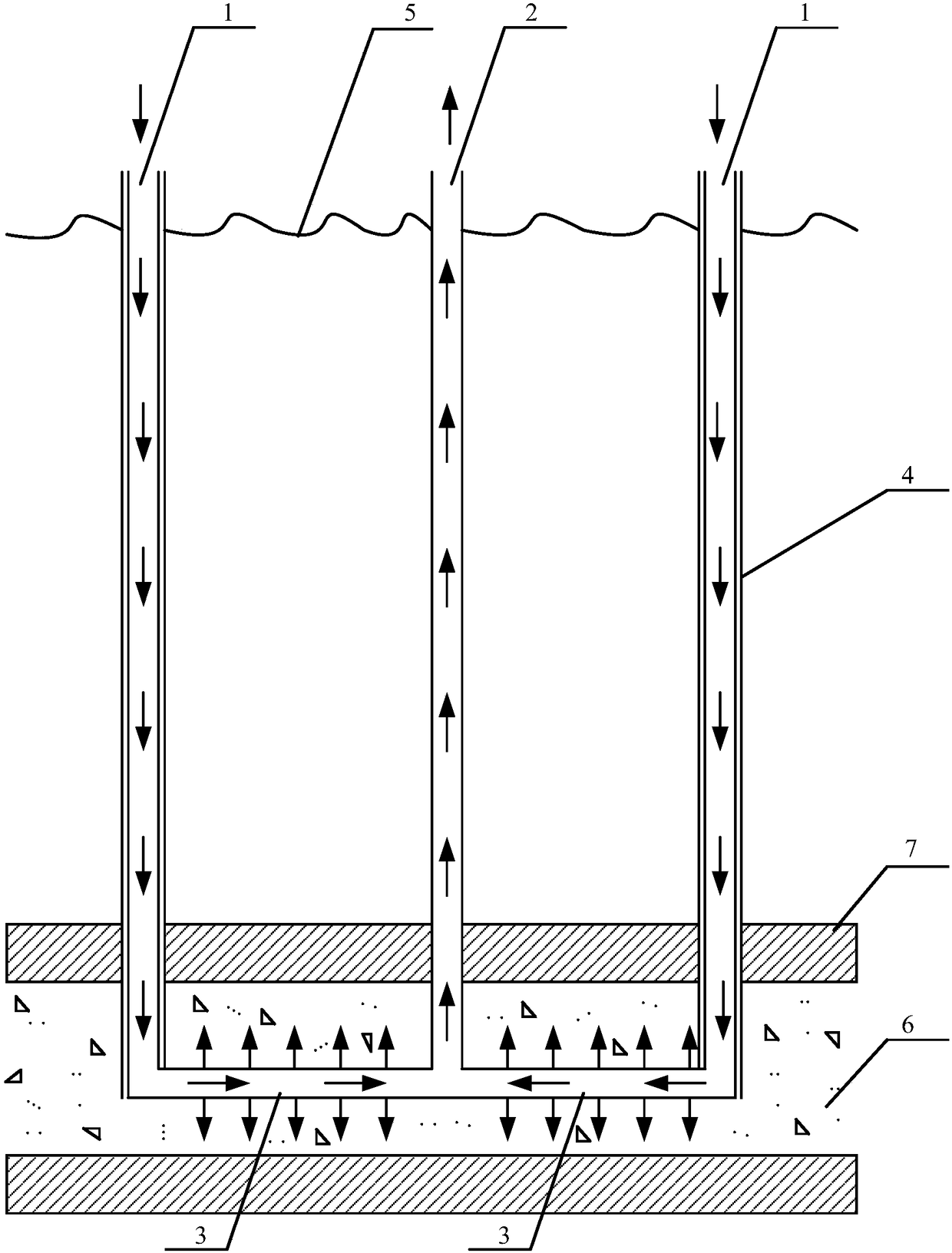

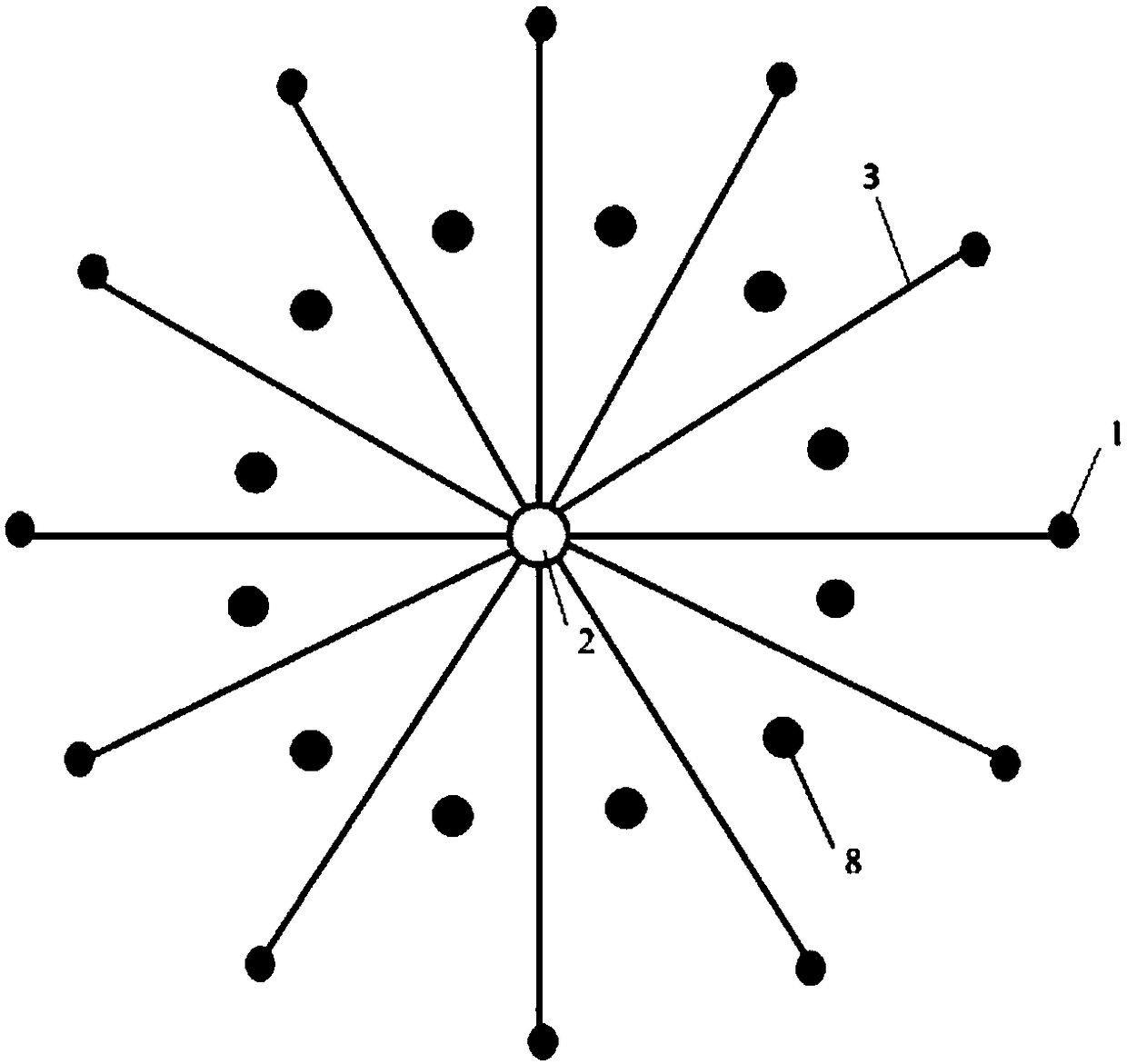

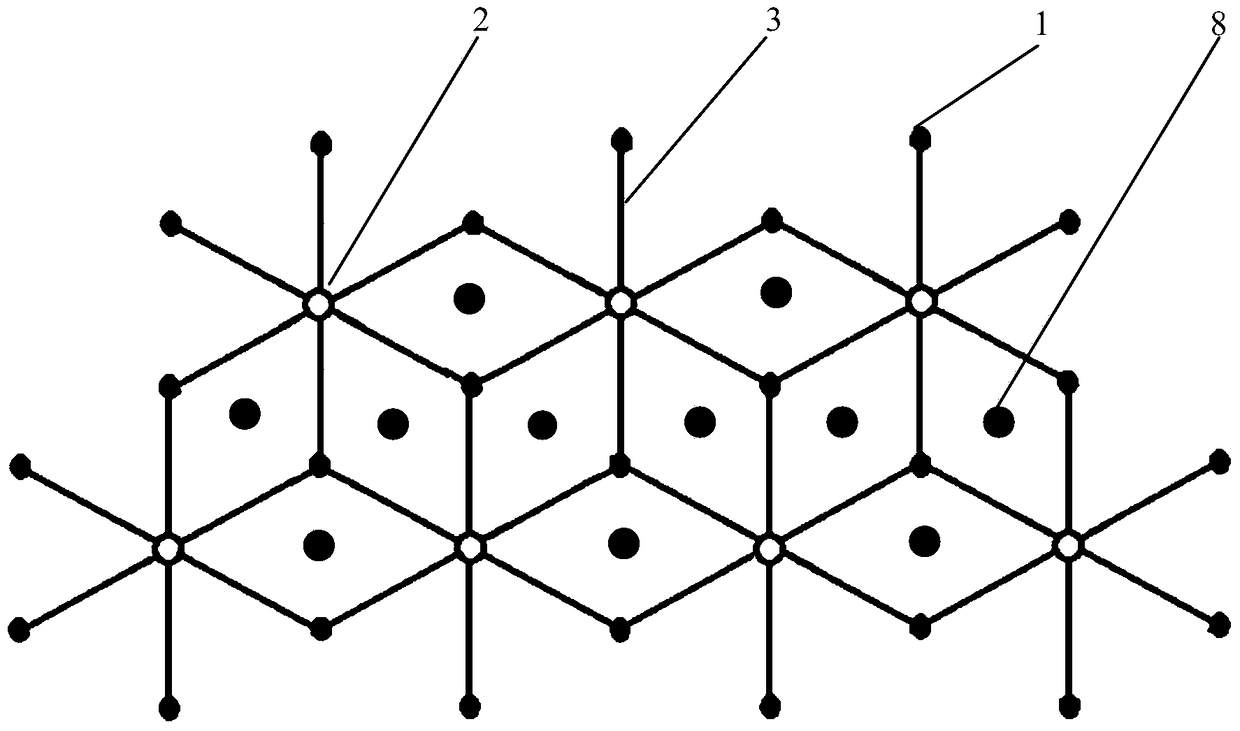

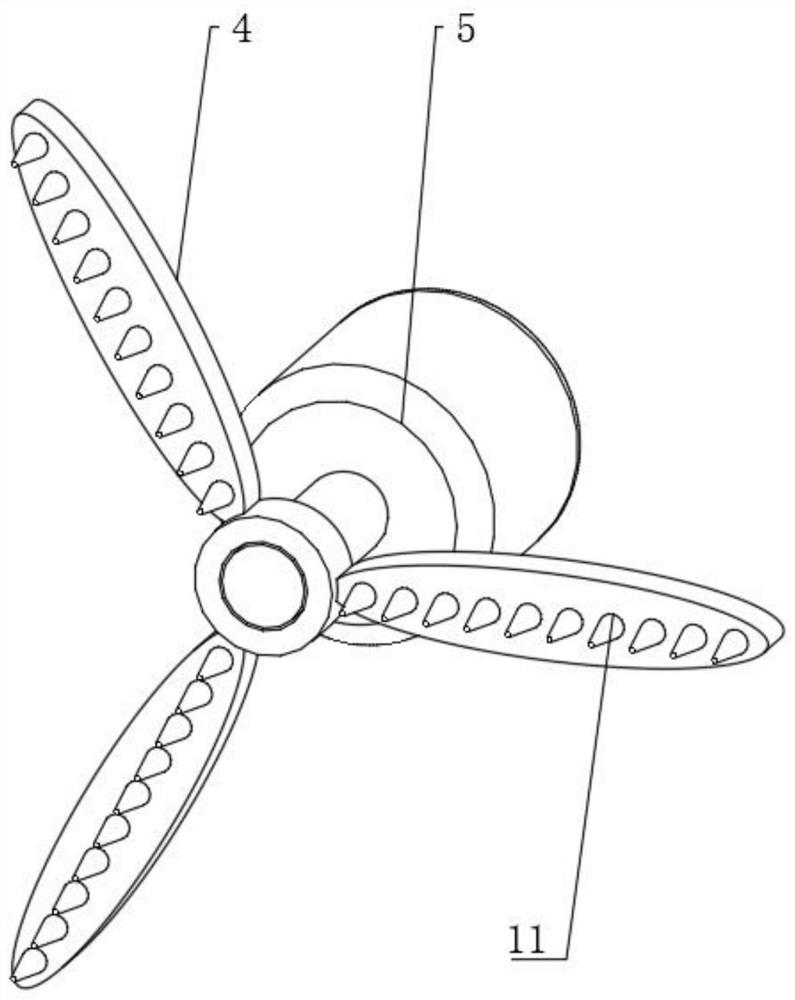

Device and method for exploiting seafloor natural gas hydrates through continuously injecting hot seawater

The invention provides a device for exploiting seafloor natural gas hydrates through continuously injecting hot seawater. The device comprises a plurality of water supply pipes (1), a plurality of heat radiation pipes (3) and at least one water outlet pipe (2), wherein the inlet end of each water supply pipe (1) is arranged at the offshore plane; the position of the inlet end of each water supply pipe (1) is higher than the sea level; the heat radiation pipes (3) are of cobweb type or hexagonal reticular or branch type or annular structures and are distributed at a seafloor hydrate layer (6); the outlet end of the water outlet pipe (2) is arranged at the offshore plane; the outlet end of the water outlet pipe (2) is flush with or below the water inlet ends of the water supply pipes (1); and the plurality of water supply pipes (1), the plurality of heat radiation pipes (3) and the at least one water outlet pipe (2) are sequentially connected to form a communicator. The hydrostatic transformation principle of the communicator is sufficiently utilized; high-temperature seawater at the sea surface layer is continuously pumped through the heat radiation pipes laid in the seafloor hydrate layer only by a low-power centrifugal pump in an ordinary model. Heat radiation pipelines are of reticular structures, so that the heat radiation efficiency can be improved; the heat radiation area is expanded; and the exploitation efficiency is improved.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

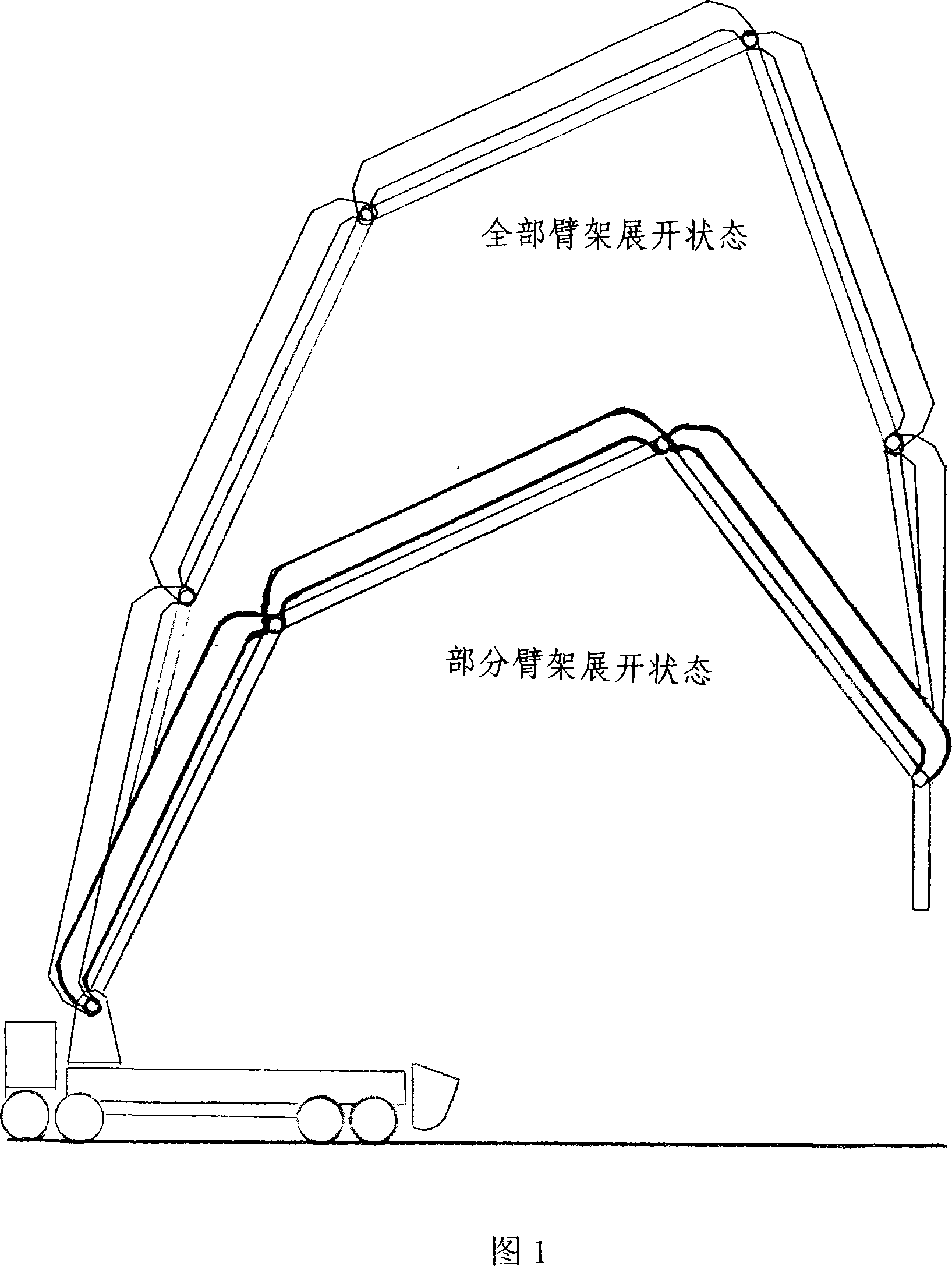

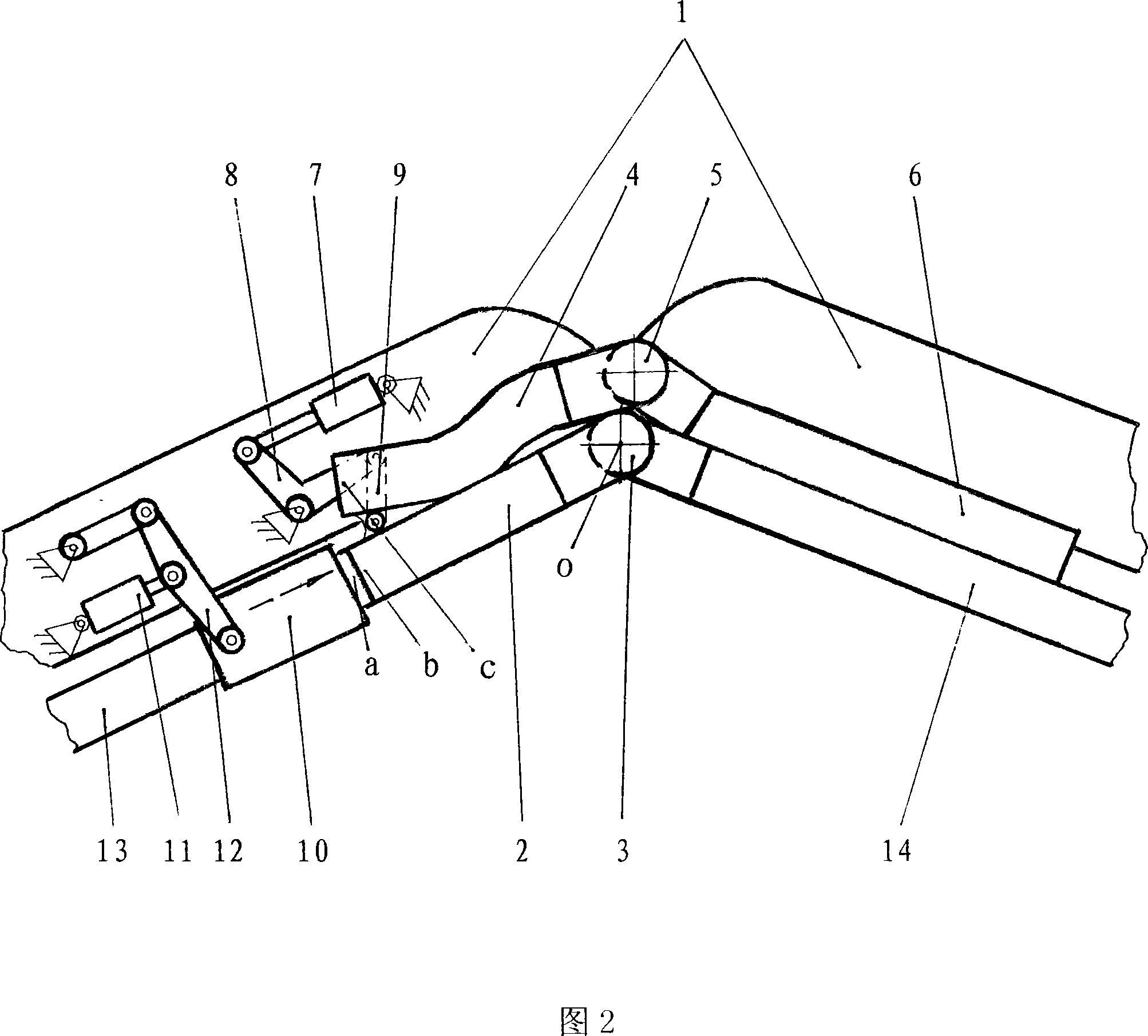

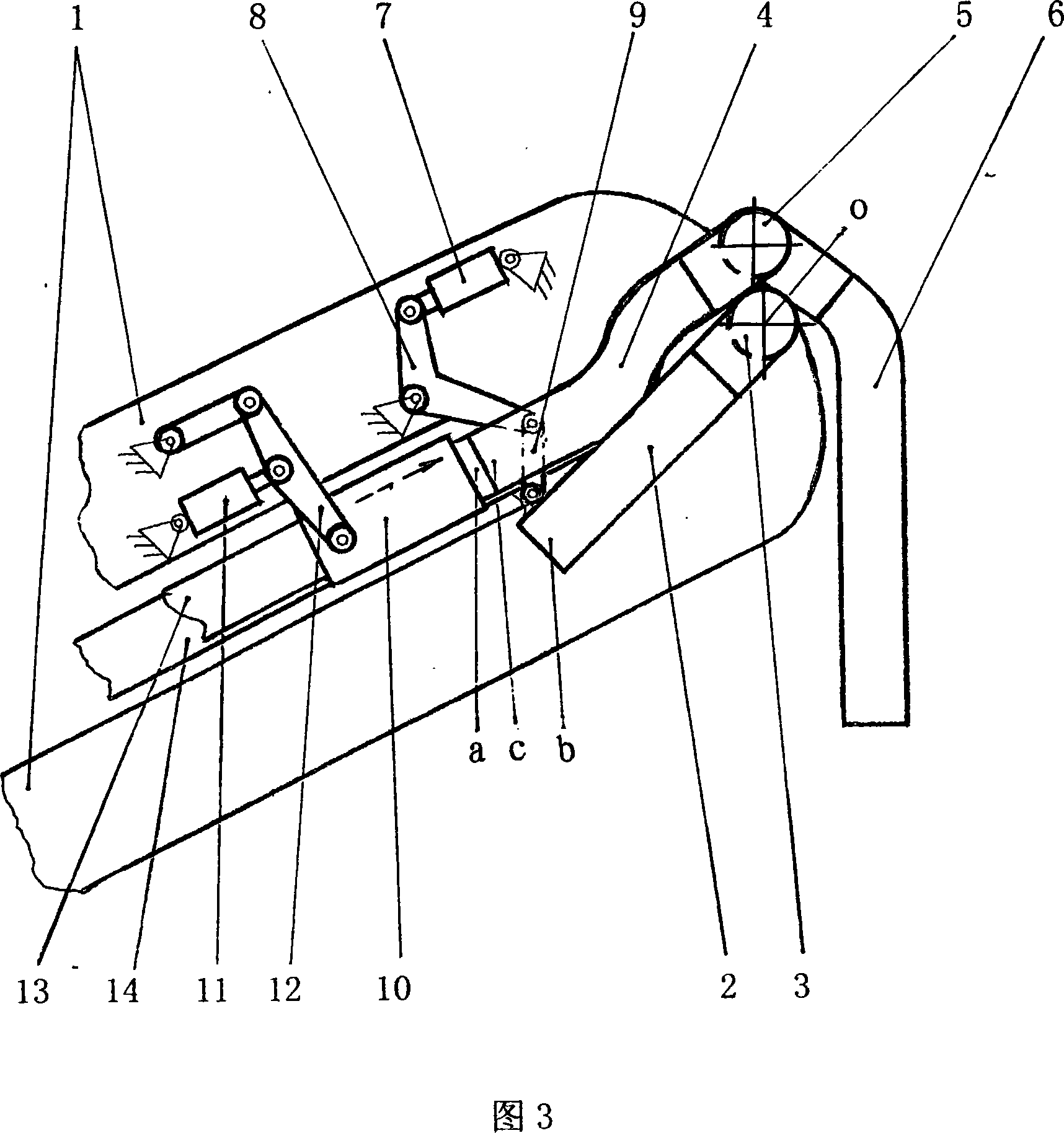

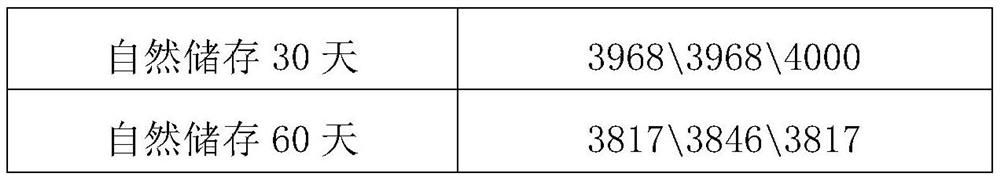

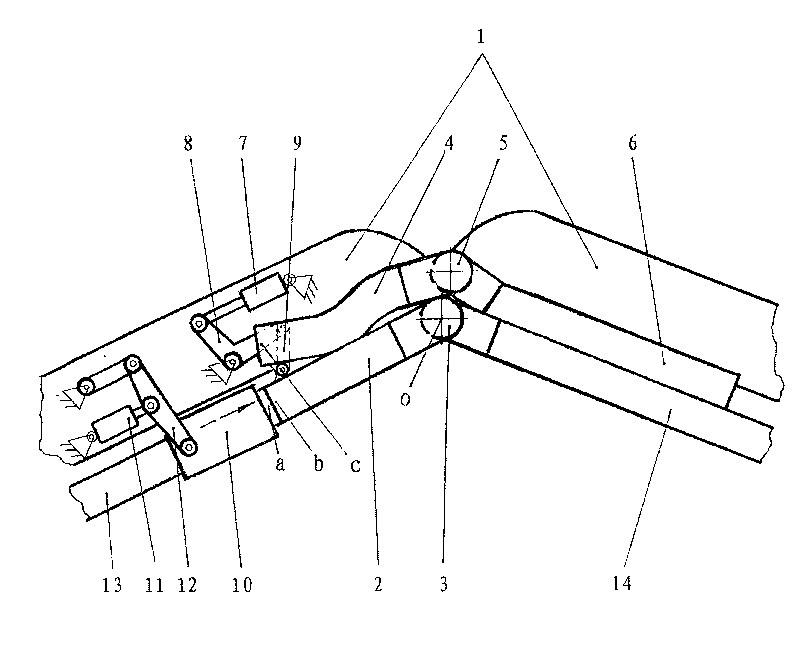

Method and device for transmitting concrete by concrete pump vehicle

InactiveCN101078298AImprove job stabilityImprove construction efficiencyBuilding material handlingEngineeringHigh pressure

The invention provides a method for pumping concrete in concrete pump truck and the device. The pumping distance of prior concrete pump truck in most construction occasions is not big but only one discharge port is set at the end of fitting pipe of arm frame in the arm frame with several decameters. So in construction all arm frames must be unfolded and by adopting high-pressure pumping, concrete passes through all fitting pipes of arm frame. Not only power is consumed and abrasion is enlarged but also efficiency and stability are decreased. Aiming at the lack of concrete pump truck existing in pumping work process, the invention provides that concrete assistant discharge device is set on the arm frame of concrete pump truck; according to the construction distance of pumping concrete fitting pipes of arm frame is switched and all or part fitting pipes of arm frame are selected to carry the construction operation of pumping concrete out. The invention can unfold proper arm frame according to the requirement and make use of corresponding fitting pipe of arm frame to construct work of pumping concrete so as to achieve purposes that the pumping pressure is decreased; energy consumption is decreased; pipe abrasion is decreased; work efficiency and stability of pumping operation are improved.

Owner:董连城

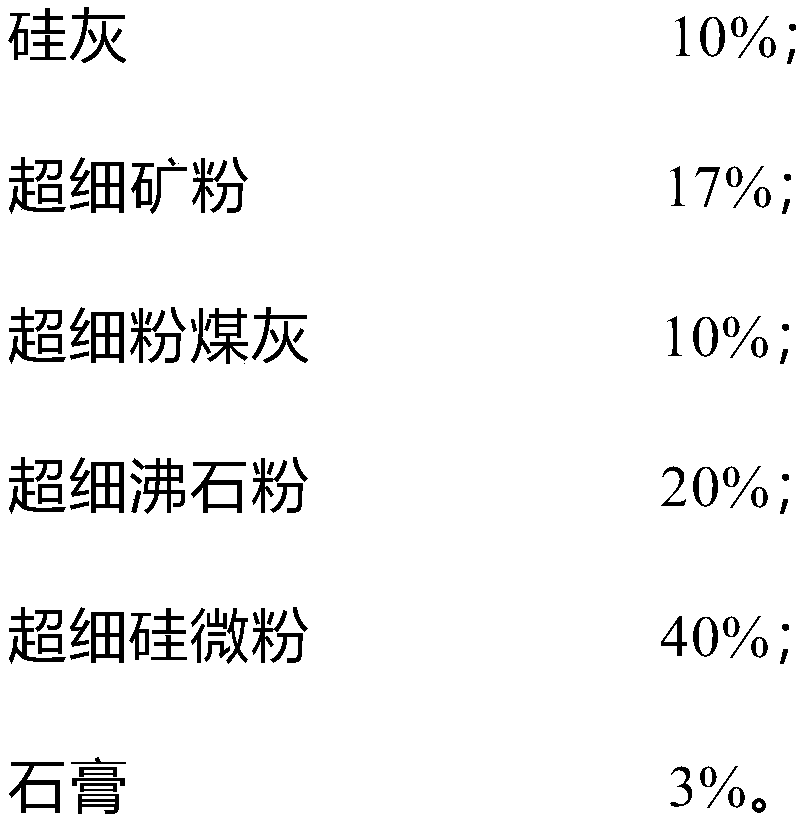

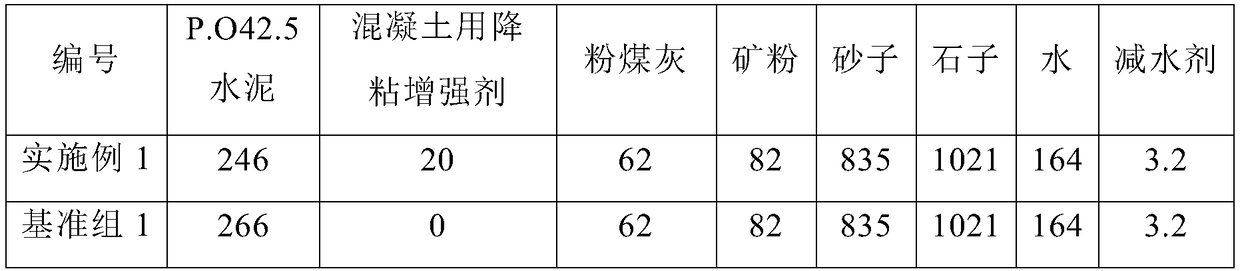

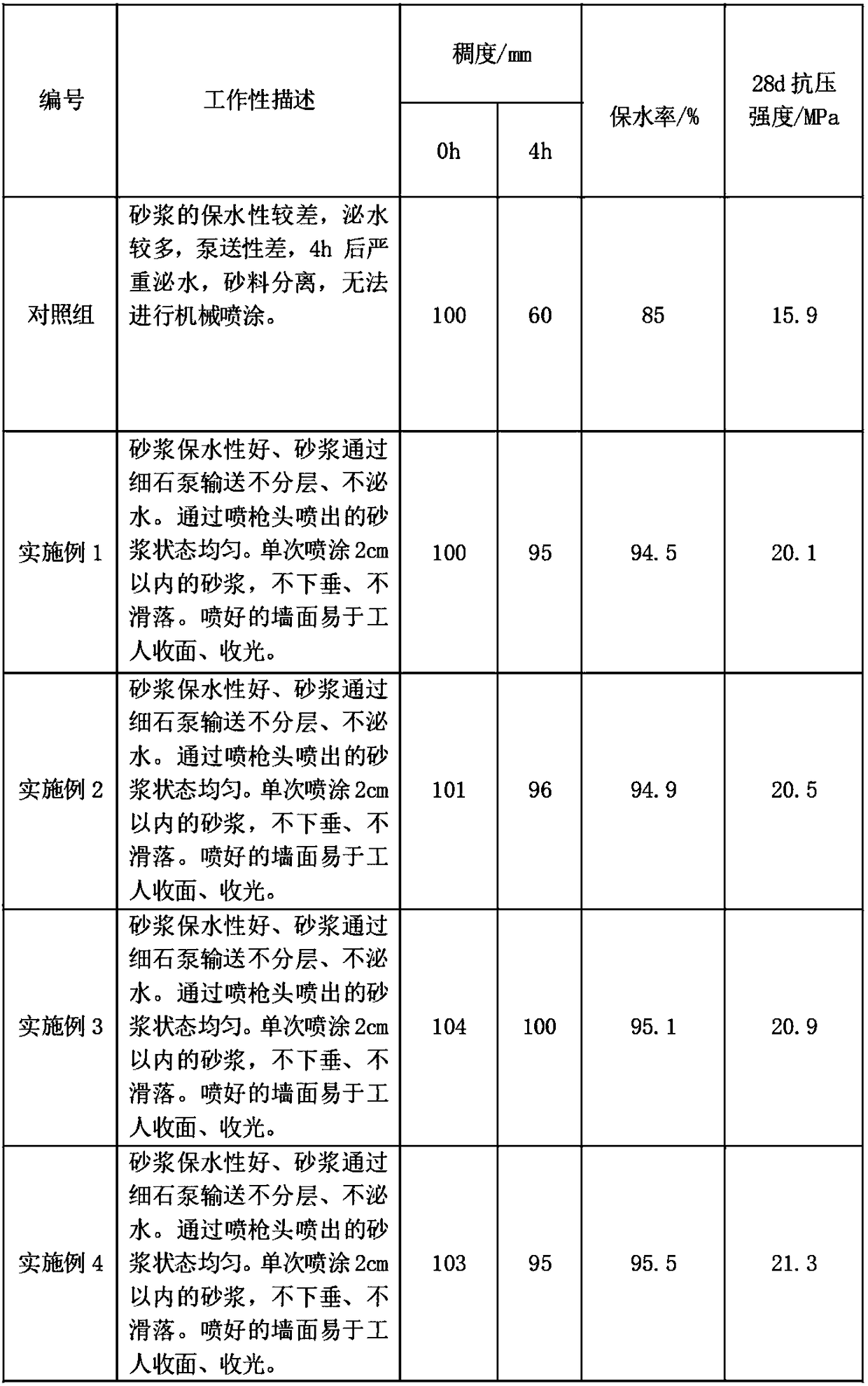

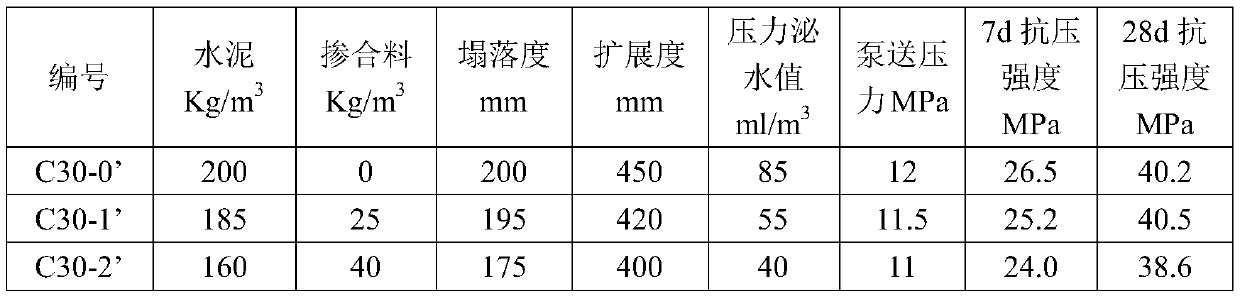

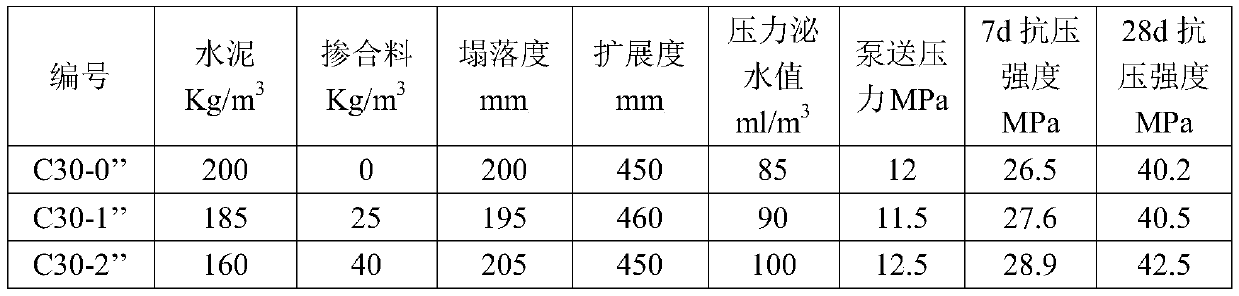

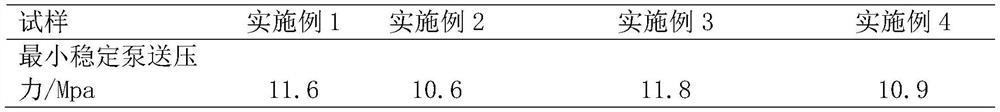

Viscosity reduction reinforcing agent for concrete and application thereof

The invention relates to a viscosity reduction reinforcing agent for concrete and application thereof, particularly relates to a functional composite mineral admixture, and belongs to the technical field of civil engineering materials. The viscosity reduction reinforcing agent for concrete is prepared from the following substances by mass percent: 10%-50% of silica fume, 5%-30% superfine slag powder, 10%-70% of superfine fly ash, 5%-20% of superfine zeolite powder, 1%-40% of superfine silica powder and 1%-10% of inorganic exciting agent. The viscosity reduction reinforcing agent for concrete,provided by the invention, is used for super-remote-distance pump concrete, super-high-rise pump concrete, high-strength high-performance concrete or super-high-performance concrete, and can obviouslyreduce the viscosity of the concrete mixture as well as improve the strength of the concrete. When the viscosity reduction reinforcing agent for concrete is used, the mixing amount of the viscosity reduction reinforcing agent for concrete is 5%-10% of the total mass of a concrete cementing material.

Owner:CHINA ACAD OF BUILDING RES +1

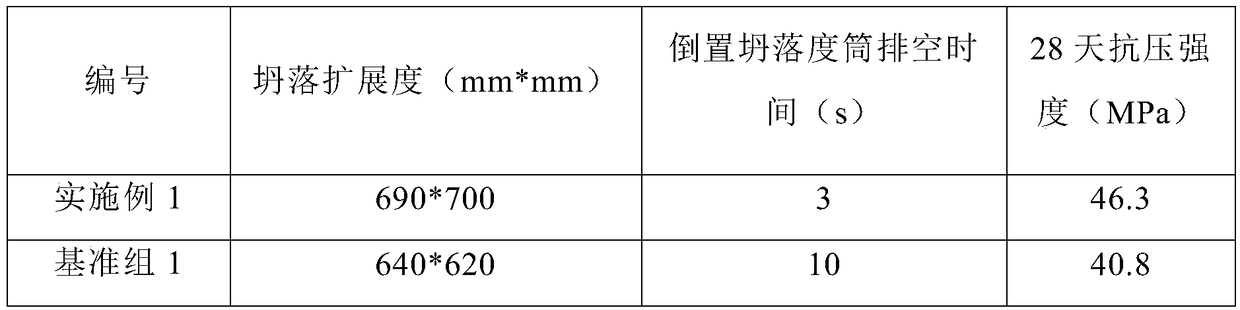

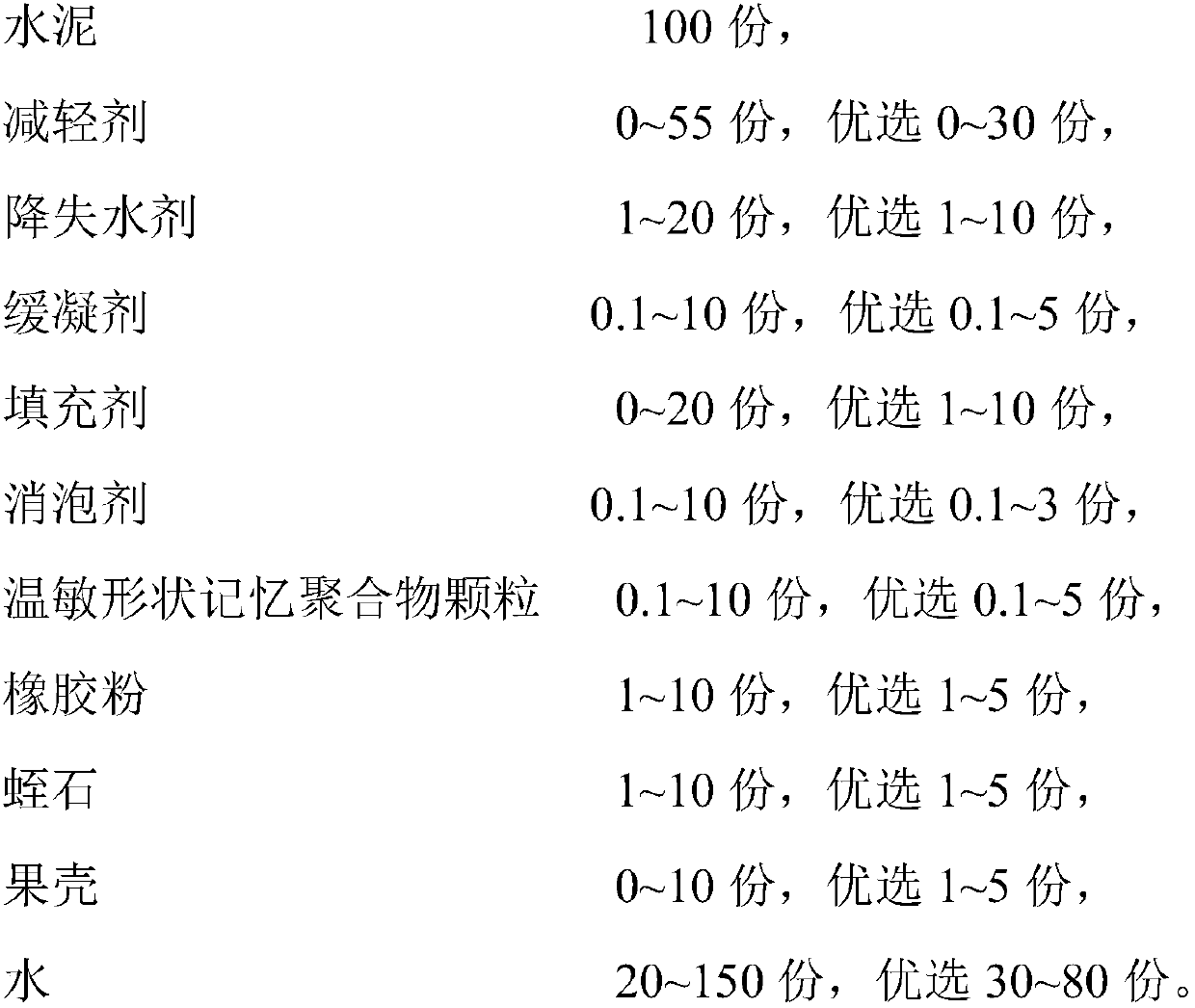

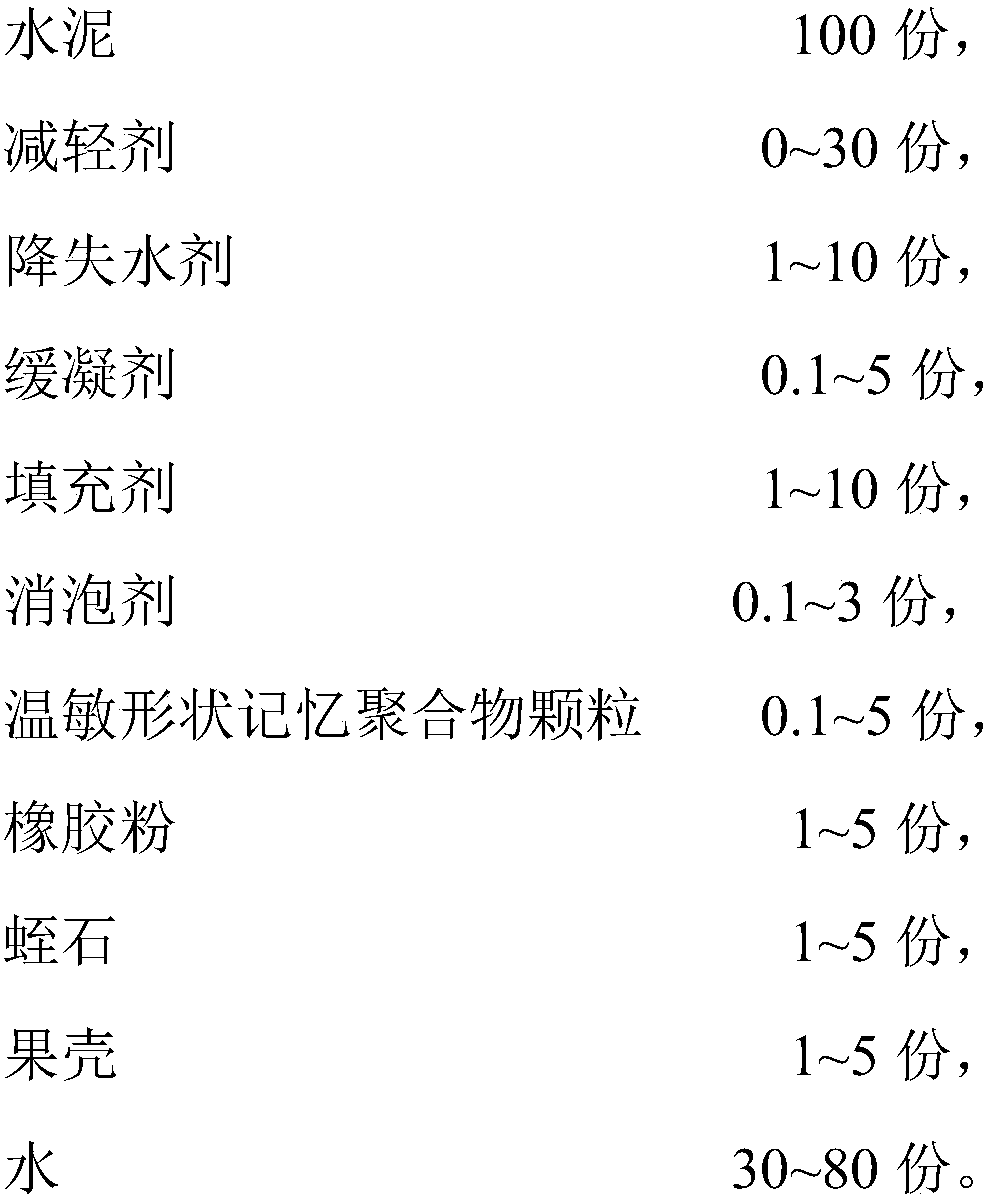

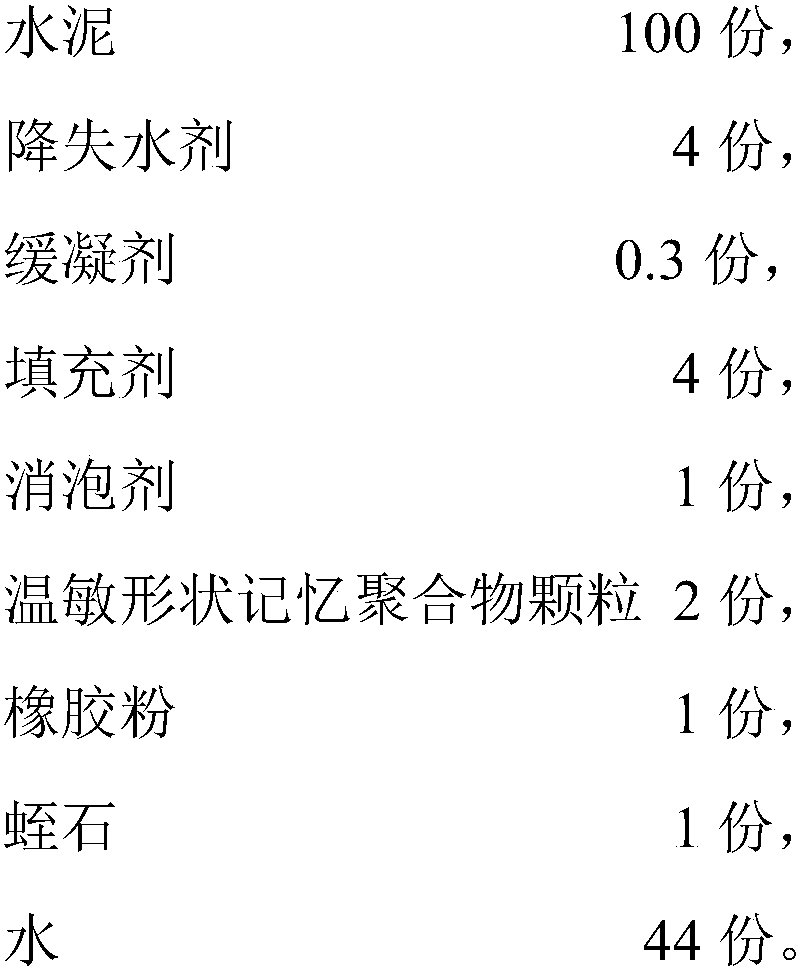

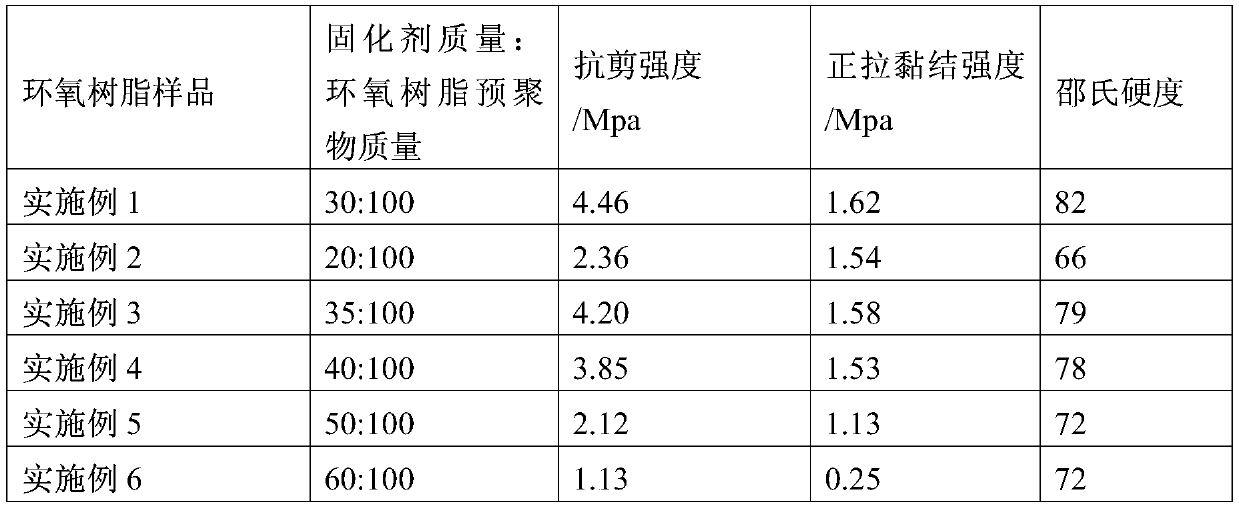

Temperature-sensitive plugging cement paste for oil well cementation and preparation method of temperature-sensitive plugging cement paste

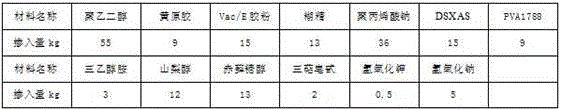

InactiveCN109516724AGood plugging effectReduce pumping pressureDrilling compositionDefoaming AgentsOil well

The invention relates to a temperature-sensitive plugging cement paste for oil well cementation and a preparation method of the temperature-sensitive plugging cement paste. The temperature-sensitive plugging cement paste for oil well cementation contains the following components in parts by weight: 100 parts of cement, 0-55 parts of lightening admixture, 1-20 parts of fluid loss agent, 0.1-10 parts of set retarder, 0-20 parts of filler, 0.1-10 parts of defoaming agent, 0.1-10 parts of temperature-sensitive shape memory polymer particles, 0-10 parts of fruit husks, 1-10 parts of rubber powder,1-10 parts of vermiculite and 20-150 parts of water. The temperature-sensitive plugging cement paste for oil well cementation, disclosed by the invention, has a good effect on plugging cracks with different sizes and has the advantages such as good plugging effect, relatively low pumping pressure and no influences to thickening time and later strength development of the cement paste for well cementation as comparison with a plugging paste made of a single inorganic material.

Owner:CHINA PETROLEUM & CHEM CORP +1

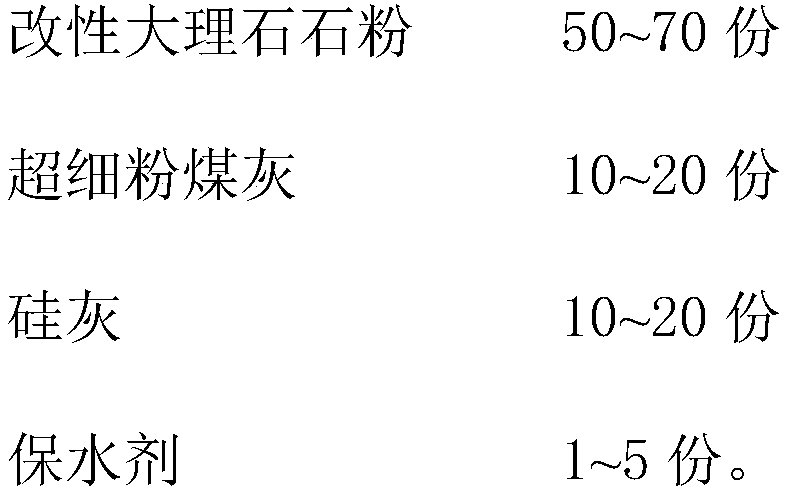

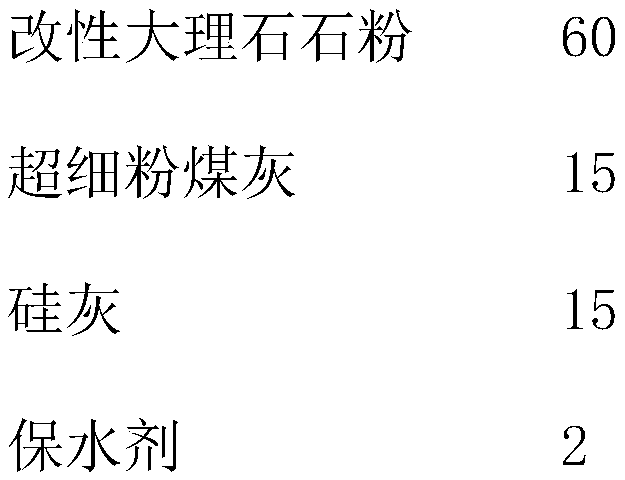

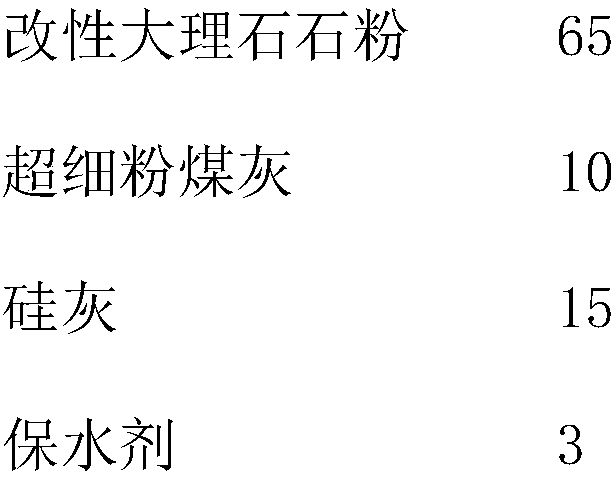

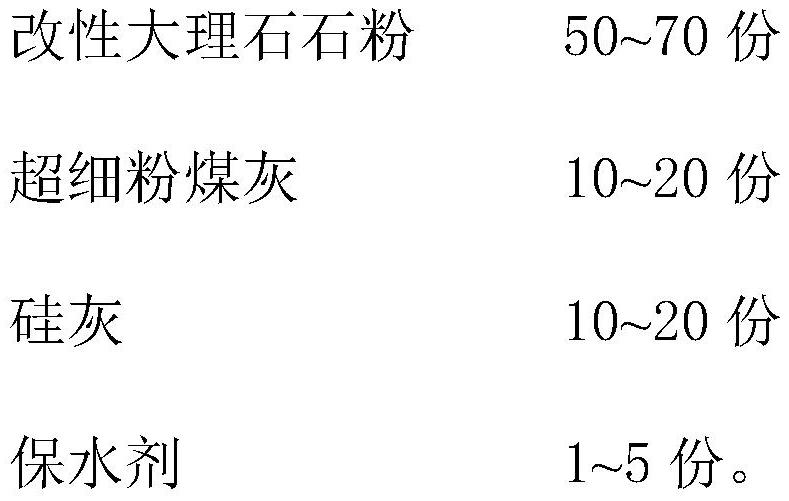

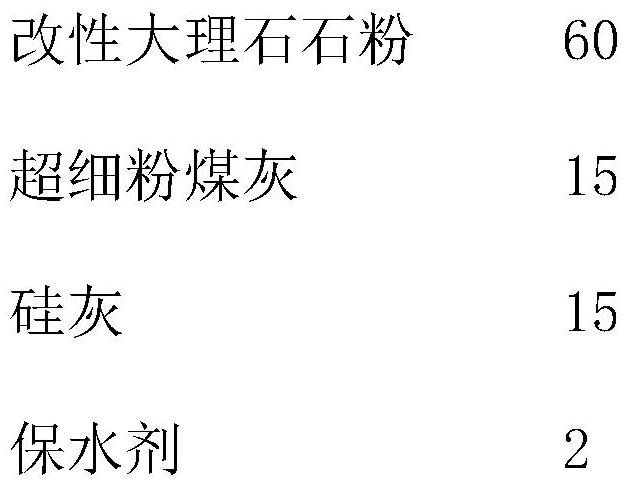

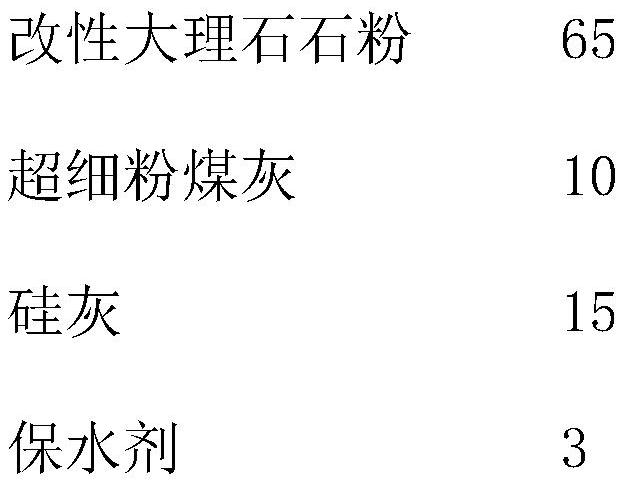

Bleeding-reduced-type concrete admixture by using marble powder as major and preparation method thereof

The invention relates to the field of building materials and in particular to a bleeding-reduced-type concrete admixture by using marble powder as a major and a preparation method thereof. The bleeding-reduced-type concrete admixture comprises the following components in parts by weight: 50-70 parts of modified marble powder, 10-20 parts of superfine coal ash, 10-20 parts of silica fume, and 1-5 parts of a water-retaining agent. The preparation method thereof comprises the following steps: simultaneously adding the water-retaining agent and the silica fume to a blender and stirring for 10-20 minutes, and adding the superfine coal ash, stirring for 10-20 minutes, finally adding the modified marble powder, and stirring for 20-30 minutes, after uniformly mixing, preparing the bleeding-reduced-type concrete admixture. The bleeding-reduced-type concrete admixture is capable of, through introducing the modified marble powder, the superfine coal ash and the silica fume and optimizing the concrete admixture, improving a concrete flow rate, improving pumping performance, improving concrete homogeneity through introducing the water-retaining agent, and reducing the concrete bleeding, and canbe extensively used for construction of pump concrete, and middle and low grade concrete.

Owner:FUJIAN KZJ NEW MATERIALS CO LTD

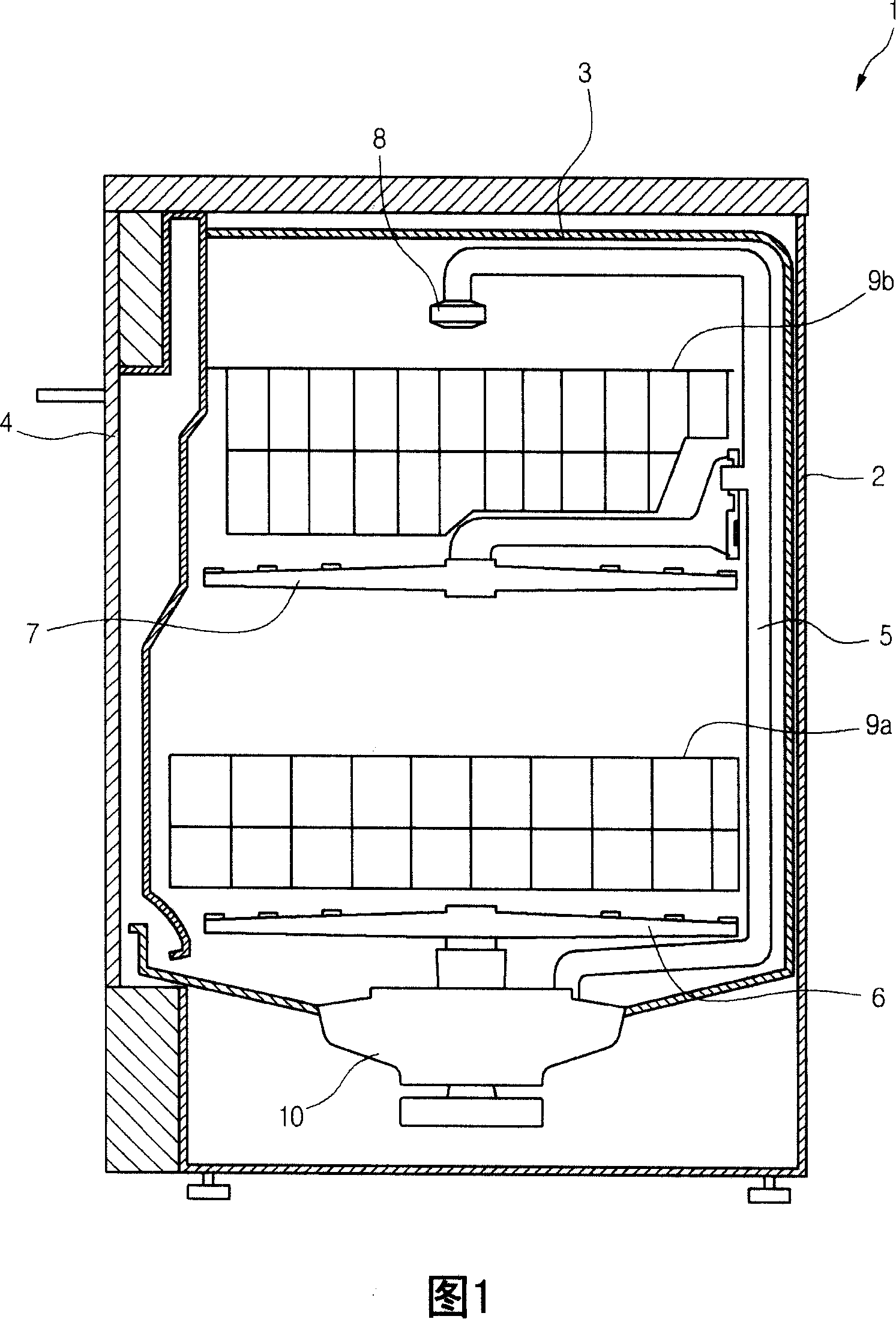

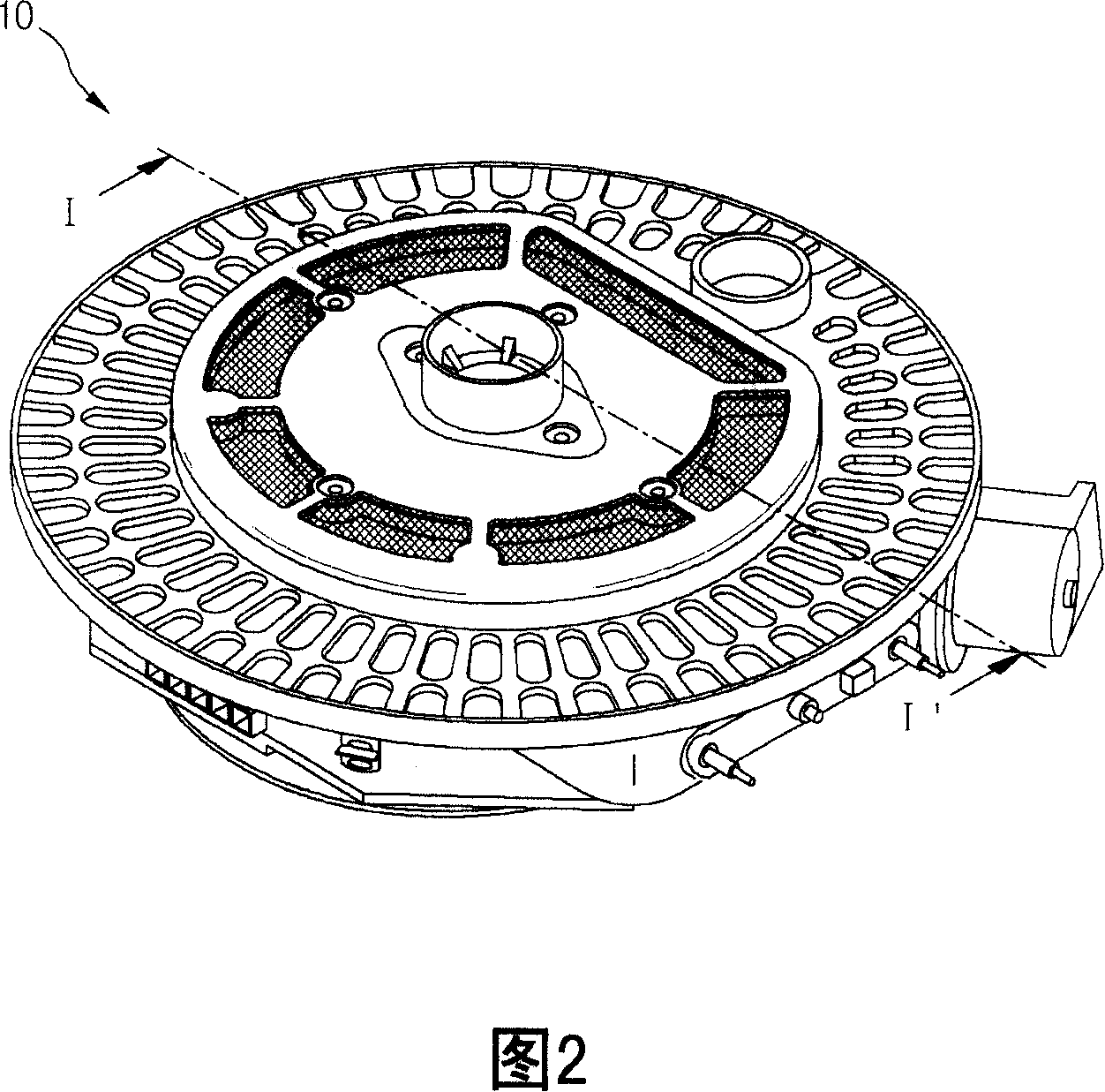

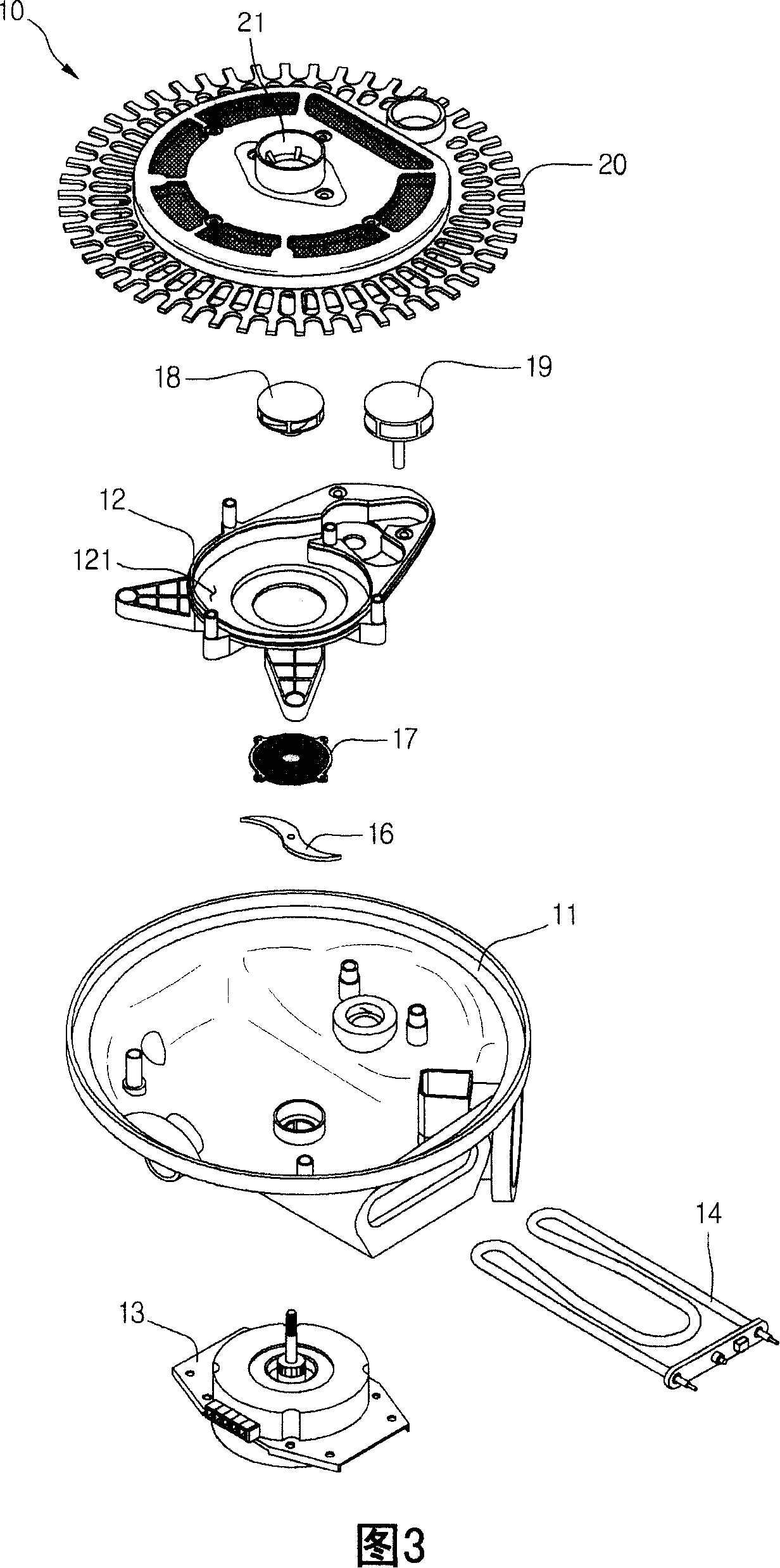

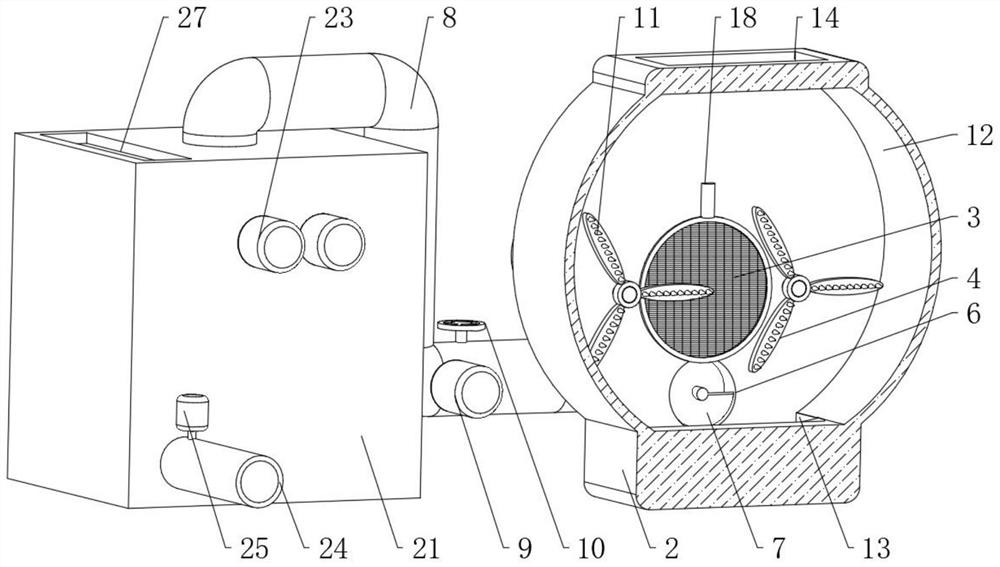

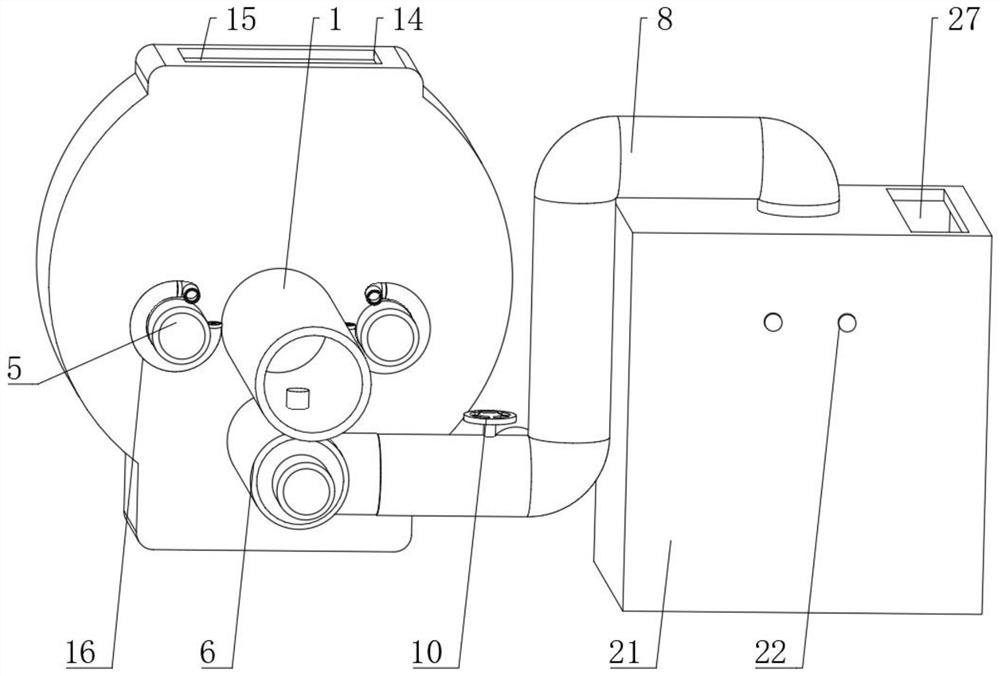

Sump for dishwasher

InactiveCN101152071ASimplify the assembly processImprove channelTableware washing/rinsing machine detailsWater circulationEngineering

A sump for a dishwasher includes a sump case for storing washing fluid, a washing pump assembly including a flow guide to pump out the washing fluid, and a filtering assembly including a flow guide to accumulate foreign particles contained in the washing fluid during the circulation of the washing fluid. The sump includes a sump cover to cover an opening of the sump case, and a self-cleaning assembly for filtering out the foreign particles directed to the flow guide. The flow guide, the sump cover and the self-cleaning assembly are thermally bonded to form a single unit.

Owner:LG ELECTRONICS INC

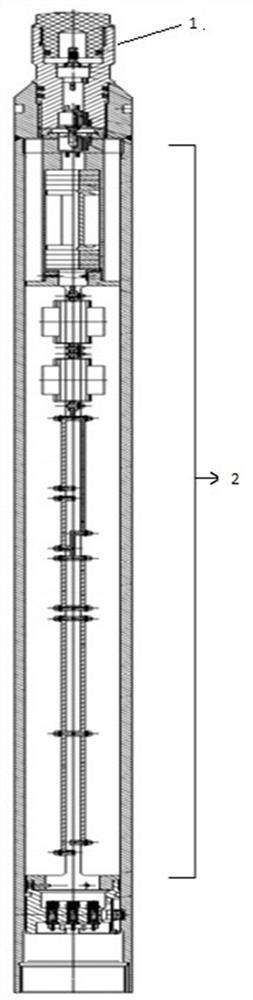

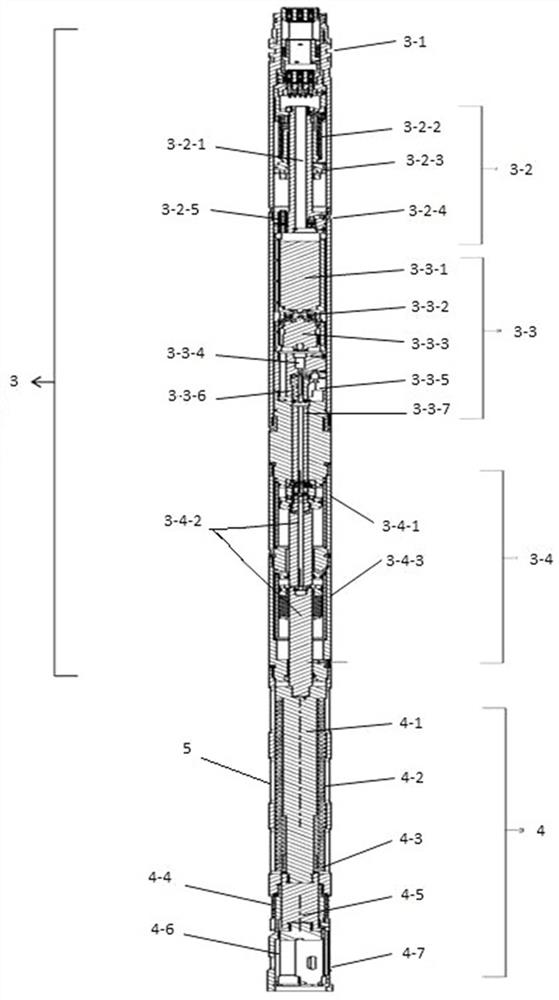

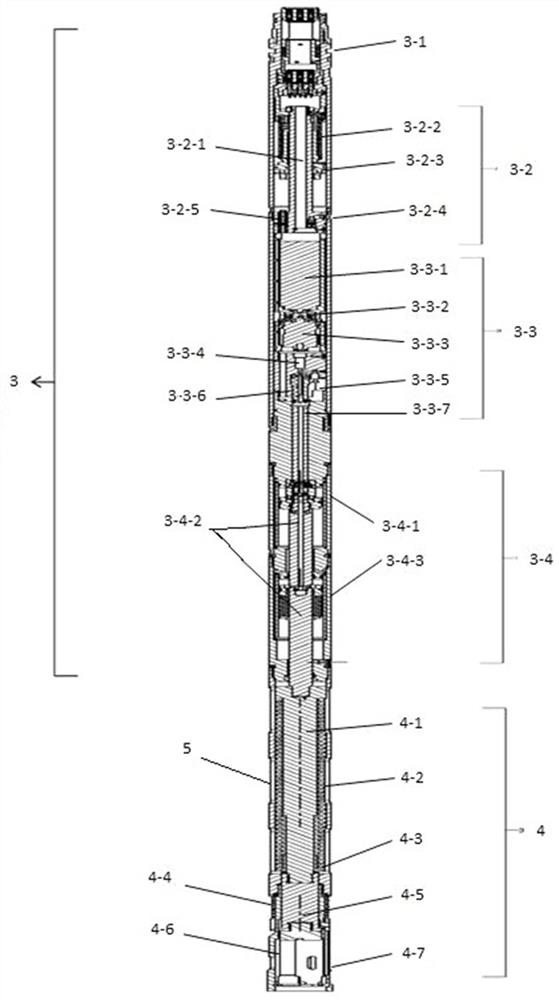

Fishing tool and method for electric hydraulic type throttler

ActiveCN111734336AImprove the success rate of salvageLow costBorehole/well accessoriesMarine engineeringElectric machinery

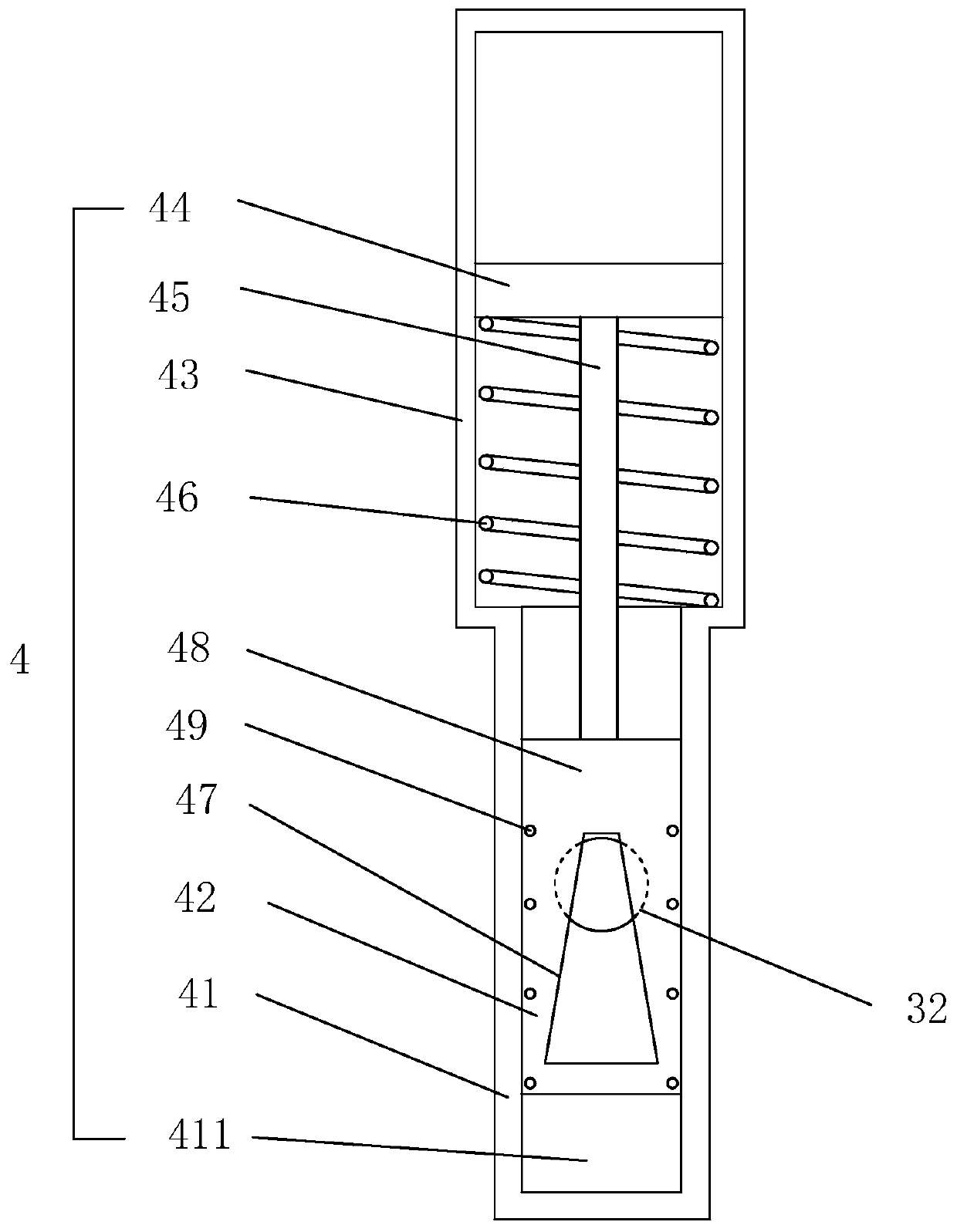

The invention provides a fishing tool and method for an electric hydraulic type throttler. The fishing tool comprises an outer shell. An upper connector for a cable to penetrate through is disposed atthe top end of the outer shell. An electronic nipple, a hydraulic drive nipple and a self-reset fishing spear nipple are encapsulated in the outer shell sequentially from top to bottom. The electronic nipple is electrically connected with the hydraulic drive nipple. The hydraulic drive nipple pushes the self-reset finishing spear nipple by hydraulic oil to grab the throttler. A motor is controlled by a ground controller to work and drives a plunger pump to push a push rod, and the push rod drives a fishing head until the throttle is unlocked, so that a fishing success rate of the downhole throttler is effectively increased, and the requirements for a safe, reliable and low-cost fishing technology and economical performance in the fishing process of the downhole throttler in a gas field can be met.

Owner:PETROCHINA CO LTD

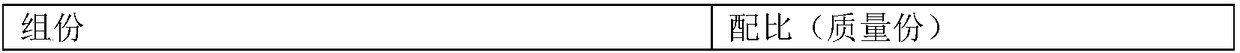

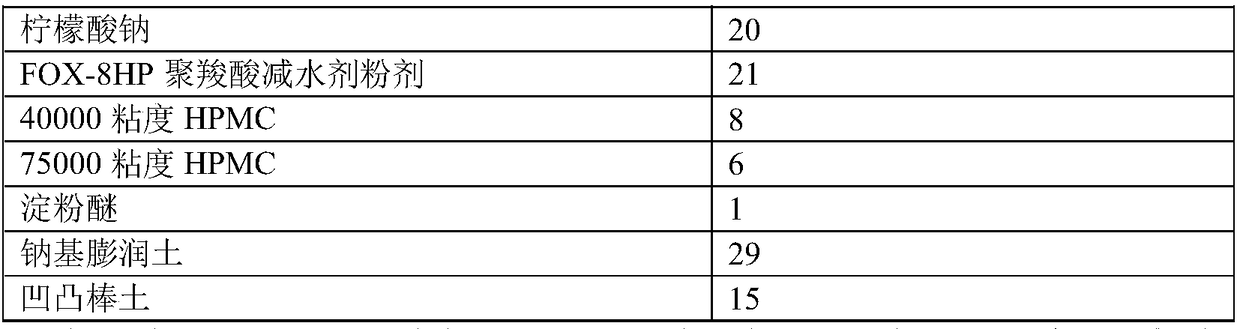

Plasticity stabilizer for mechanical spraying mortar

The invention discloses a plasticity stabilizer for mechanical spraying mortar. The plasticity stabilizer comprises the following ingredients in parts by mass: 20-22 parts of a retarder, 20-22 parts of a water reducer, 12-14 parts of cellulose ether, 0.5-1 part of a thixotropic agent, 25-30 parts of bentonite and 15-20 parts of attapulgite. The plasticity stabilizer is applicable to the mechanicalspraying mortar, and can improve thixotropy, water retention, pumpability and storability of the mortar.

Owner:FUKE TECH (SUZHOU) CO LTD

Pumping concrete admixture capable of improving pumpability and preparation method thereof

The invention discloses a pumping concrete admixture capable of improving pumpability and a preparation method thereof. The admixture comprises the following raw materials (by weight): 70-80 parts ofcopper tailings, 20-30 parts of granulated blast-furnace slag, and 0-0.1 part of an additive. The additive is composed of triethanolamine, polyvinyl alcohol and a polycarboxylic plasticizer. The copper tailings from wet mill concentration contain lots of fine particles of less than 5 um. Through processes such as surface modification, drying, grinding, etc., the concrete admixture capable of effectively reducing bleeding and segregation of pumping concrete and remarkably enhancing pumpability can be prepared. Solid wastes can be largely utilized, the cost of the product is low, and the economic value is high. Thereby, the preparation method accords with the national circular economy and sustainable development policy.

Owner:ANHUI TONGGUAN (LUJIANG) MINING CO LTD

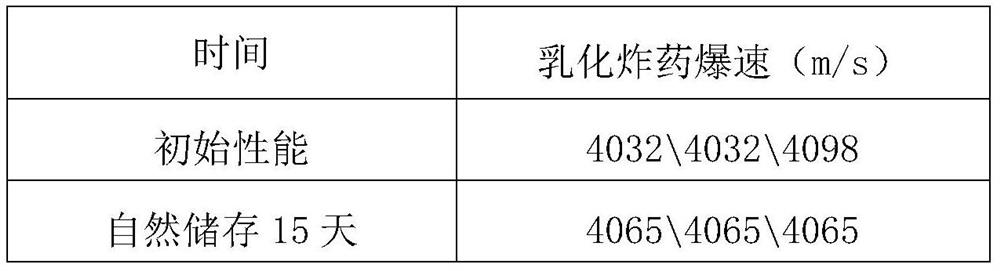

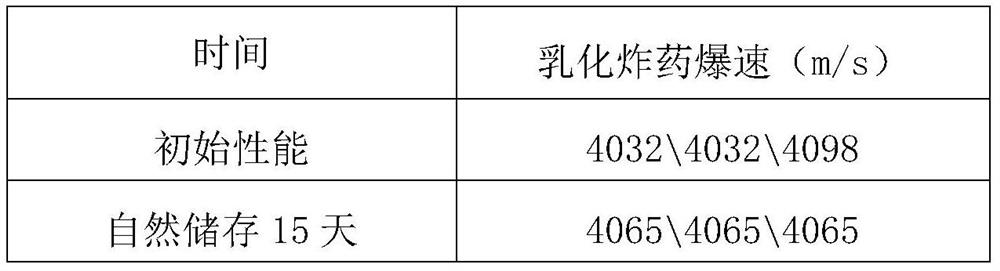

Oil phase for medium-low temperature sensitization process emulsion explosive and prepared from coal-to-oil intermediate product and preparation method thereof

ActiveCN113024334AGood liquidityReduce pumping pressureNon-explosive/non-thermic compositionsWaxChemistry

The invention disclosesan oil phase for a medium-low temperature sensitization process emulsion explosive and prepared from a coal-to-oil intermediate product. Theoil phase comprises the coal-to-oil intermediate product, a wax material, an SP-80 emulsifier and a polymer surfactant according to a weight ratio of (45-55): (15-20): (25-30): (5-10); and the four materials are metered and added into a mixing tank to be heated, stirred and mixed for 40-70 min, the temperature is controlled to be 75 + / -5 DEG C, and the materials are mixed to form the composite oil phase, wherein the coal-to-oil intermediate product is a semi-finished product in the coal-to-oil production process, namely the coal-to-oil intermediate product. The oil phase has the advantages that no other oil phase material is added, various performance indexes of the produced emulsion explosive can completely reach the national standard, and the product has the advantages of good fluidity, low pumping pressure and the like. The composite oil phase has the advantages of higher calorific value, favorable safety performance, convenience in use, low price, wide sources of various raw materials and higher economic benefit.

Owner:GEZHOUBA YIPULI HUBEI CHANGTAI CIVIL EXPLOSIVE

Fracturing well completion method

InactiveCN108868729AIncrease displacementReduce pumping pressureFluid removalLight drivenIndustrial Oils

The invention discloses a fracturing well completion method. The method is applied to the reservoir exploitation of low permeability oil and gas reservoirs, tight oil or shale oil and the like. The method comprises the steps that a light drive pipe is adopted to perform fracturing, a spile bridge plug is prefabricated in a well shaft above a production layer using a constant oil pipe after fracturing is conducted, the bridge plug is used for isolating the reservoir in pump lowering well completion or subsequent pump inspection operation process to prevent external liquid from contacting the reservoir, and a sealing plug at the bottom of a production column is used for switching on and off a production pipeline in the bridge plug. Fracturing needs to be conducted on the low permeability oiland gas reservoirs, the tight oil or the shale oil to obtain industrial oil gas flow, if conventional operation is conducted, well killing needs to be conducted in the pump lowering or pump inspection operation process, well killing liquid in the well shaft easily enters a stratum to damage the stratum, and the yield after fracturing is conducted is reduced. If pressurizing operation is conducted, the problems of long construction period and high cost exist, and an electric pump cannot be lowered during pressuring operation. The method overcomes the defects of the conventional operation and the pressurizing operation, and efficient exploitation of the low permeability oil and gas reservoirs is achieved.

Owner:CNPC BOHAI DRILLING ENG

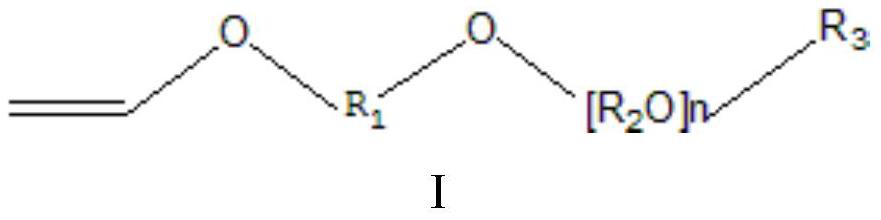

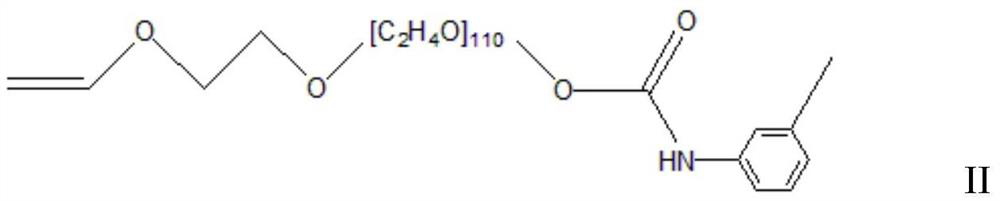

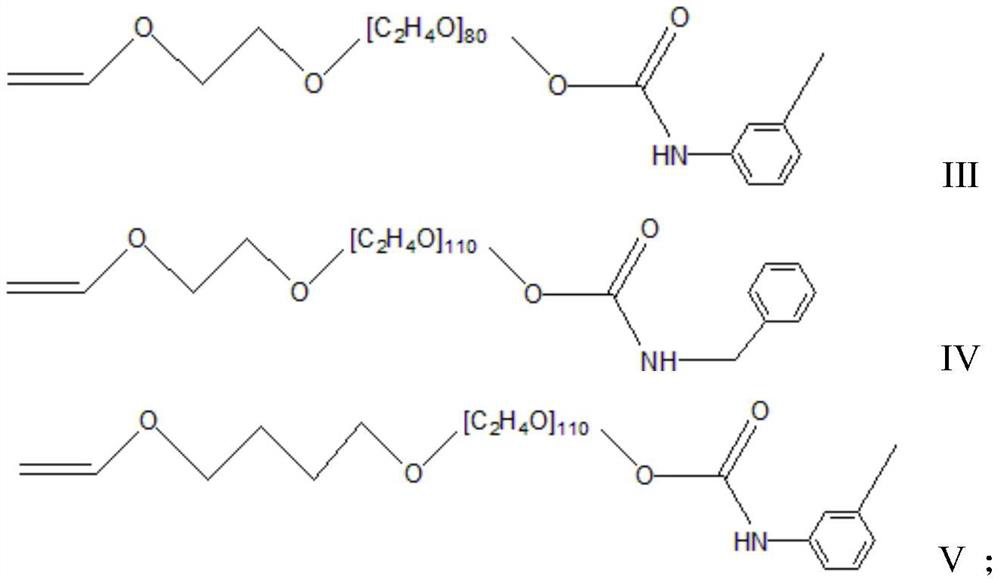

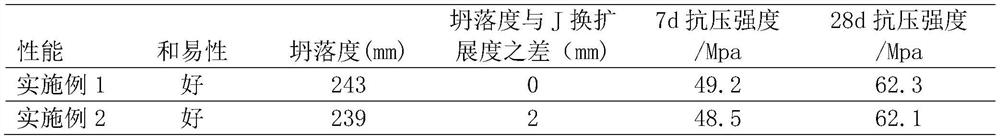

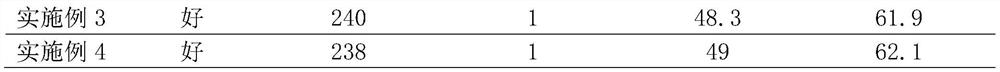

Viscosity reduction type liquid phase composition, preparation method and application thereof

The invention relates to a viscosity reduction type liquid phase composition, a preparation method and application thereof, in particular to a viscosity reduction type water reducing agent applied tosimilar construction modes such as tubular piles and sleepers, a preparation method and application thereof, and belongs to the technical field of concrete admixtures. The invention provides a liquidphase composition, which comprises the following components: (1) one or two or more polymers P selected from polymers of polyether macromonomers and micromonomers; and (2) one or two or more water reducing agents Q selected from a water reducing type polycarboxylate water reducing agent, a slow release type polycarboxylate water reducing agent and a slump retaining type polycarboxylate water reducing agent; wherein the proviso is that the liquid phase composition comprises two or more polymers P or two or more water reducing agents Q. The liquid phase composition disclosed by the invention canbe widely applied to multiple fields of commercial concrete of pumping type tubular piles, high-strength concrete pumping and high stone powder machine-made sand, and meets the requirements of different application fields such as tubular piles or sleepers on the performance of concrete admixtures.

Owner:联泓(江苏)新材料研究院有限公司 +1

Self-compacting concrete and preparation method thereof

InactiveCN111792882ALow fluidity water-binder ratioHigh strengthSolid waste managementMining engineeringCrushed stone

The invention discloses a self-compacting concrete and a preparation method thereof. The self-compacting concrete is prepared from 112 to 154 parts of cement, 95 to 125 parts of modified mineral powder, 75 to 85 parts of coal ash, 800 to 1100 parts of broken stone, 195 to 233 parts of coarse sand, 455 to 580 parts of fine sand, 110 to 150 parts of water and 8 to 12 parts of an additive. The concrete is low in water-binder ratio, high in strength, easy to operate, small in pumping pressure and long in pumping distance, and the compactness and compressive strength of the concrete are improved.

Owner:颜小淋

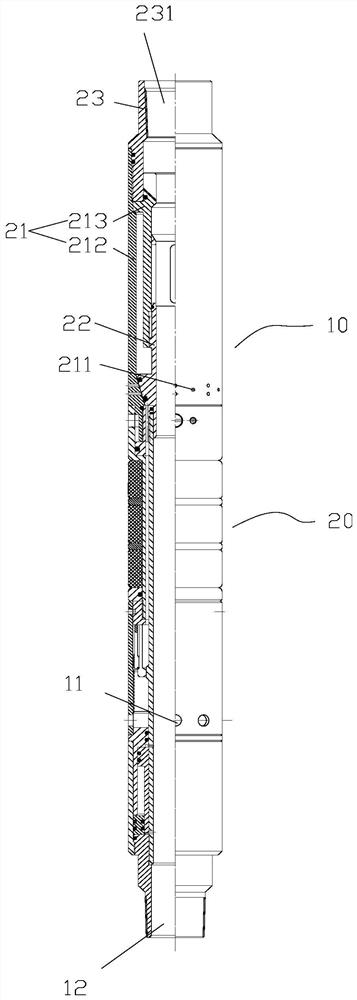

Packer

PendingCN114837596AReduce pumping pressureIncrease displacementFlushingSealing/packingEngineeringElectric control

The invention provides a packer which comprises a packing part and a well washing assembly connected with the packing part, the well washing assembly comprises a well washing sleeve assembly and a concentric adjusting cylinder, the well washing sleeve assembly is connected with the packing part, a liquid inlet hole is formed in the well washing sleeve assembly, and the well washing assembly is controlled by an electric control mechanical arm; the concentric adjusting cylinder is movably arranged in the well washing sleeve assembly in the axial direction of the well washing sleeve assembly, the concentric adjusting cylinder is provided with a sealing position for shielding the liquid inlet hole and a liquid inlet position for avoiding the liquid inlet hole, and the outer wall of the concentric adjusting cylinder is in threaded fit with the well washing sleeve assembly so that the concentric adjusting cylinder can be screwed in and screwed out of the well washing sleeve assembly; according to the packer, on one hand, the problem of high-pressure differential separate injection is solved, on the other hand, the pump pressure for well washing is reduced, the well washing displacement is improved, separate injection of a well with large interlayer pressure difference (within 15 MPa) can be met, meanwhile, a spring structure of a common high-pressure-difference well washing packer is omitted, and the service time of the packer is prolonged.

Owner:PETROCHINA CO LTD

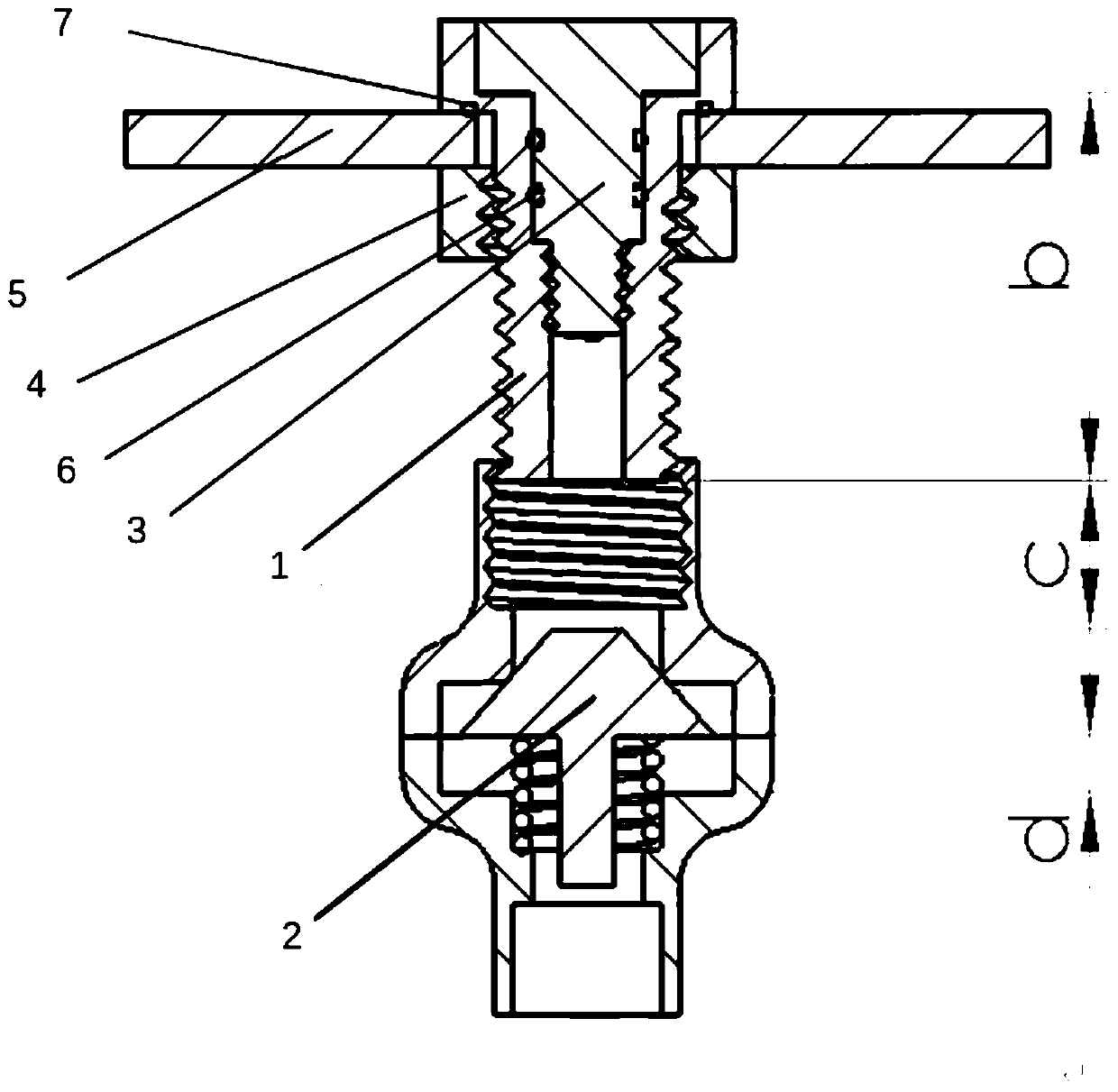

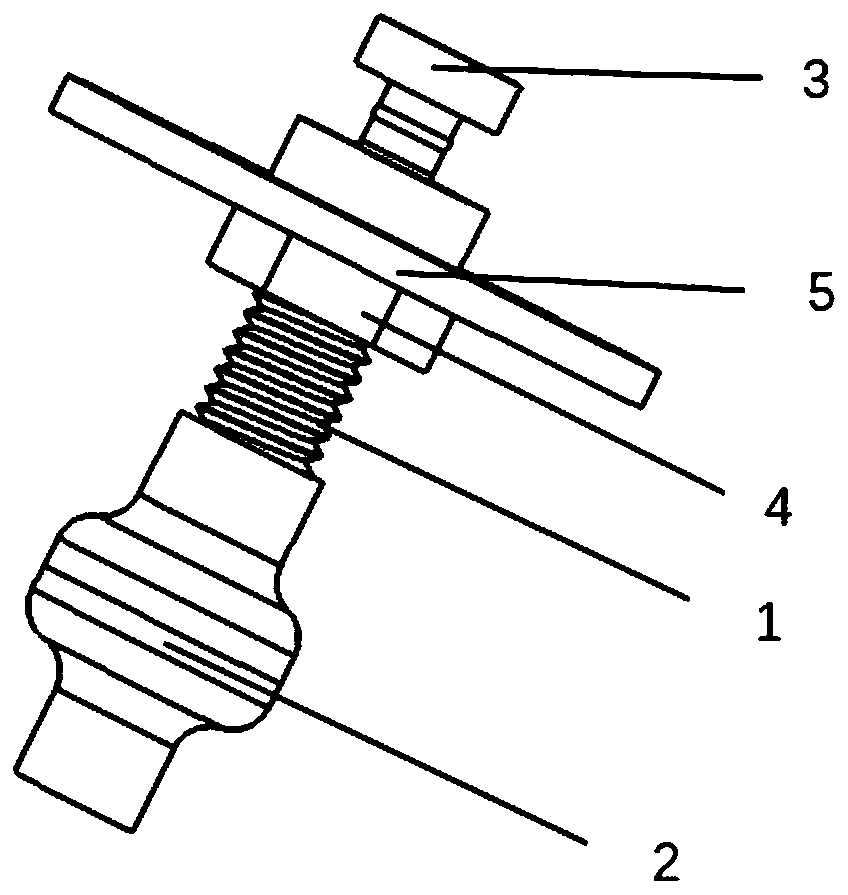

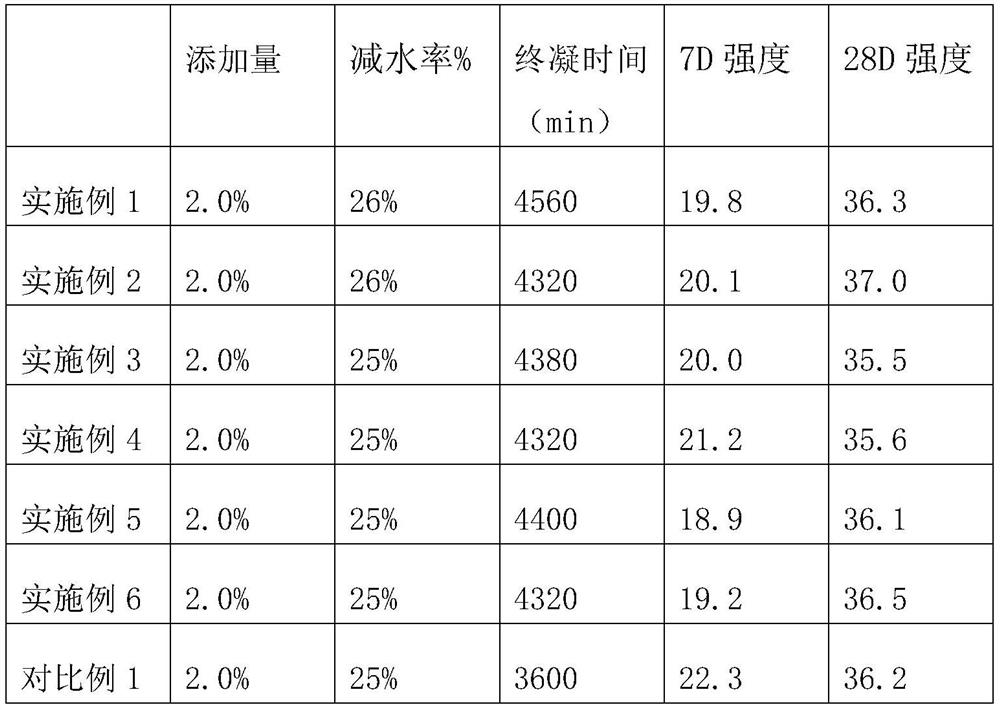

Bidirectional gas valve kit for sealed cabin of underwater robot and gas nozzle matched therewith

PendingCN111219505APrevent backflowSolve the problem of instantaneous gas backflowCheck valvesPipe elementsStructural engineeringUnderwater robot

The invention discloses a bidirectional gas valve kit for a sealed cabin of an underwater robot and gas a nozzle matched therewith. The bidirectional gas valve kit comprises a ventilating bolt A, a ventilating bolt B, a plug and a nut. The ventilating bolt A is mounted on a cover of the sealed cabin through the nut, the lower end of the ventilating bolt A is located outside the cover of the sealedcabin and the lower end of the ventilating bolt A is located in the cover of the sealed cabin, and the lower end of the ventilating bolt A is connected to the ventilating bolt B through a thread; andthe plug is mounted at the upper end of the ventilating bolt A. The bidirectional gas valve kit can restore quickly by means of deformation of a spring at the moment of being taken away after suckingand pressurizing the sealed cabin. A valve element of the ventilating bolt B is ejected to an upper cover by the spring to isolate the cabin and outside, so that air backflow during suction or pressurizing due to pressure difference between the indie and outside of the cabin is avoided, and therefore, it is closer to an ideal condition of sucking and pressurizing the sealed cabin. The bidirectional gas valve kit sucks and pressurizes the sealed cabin at one step, so that the maintenance and preparation work efficiency of the underwater robot is improved.

Owner:DALIAN MARITIME UNIVERSITY

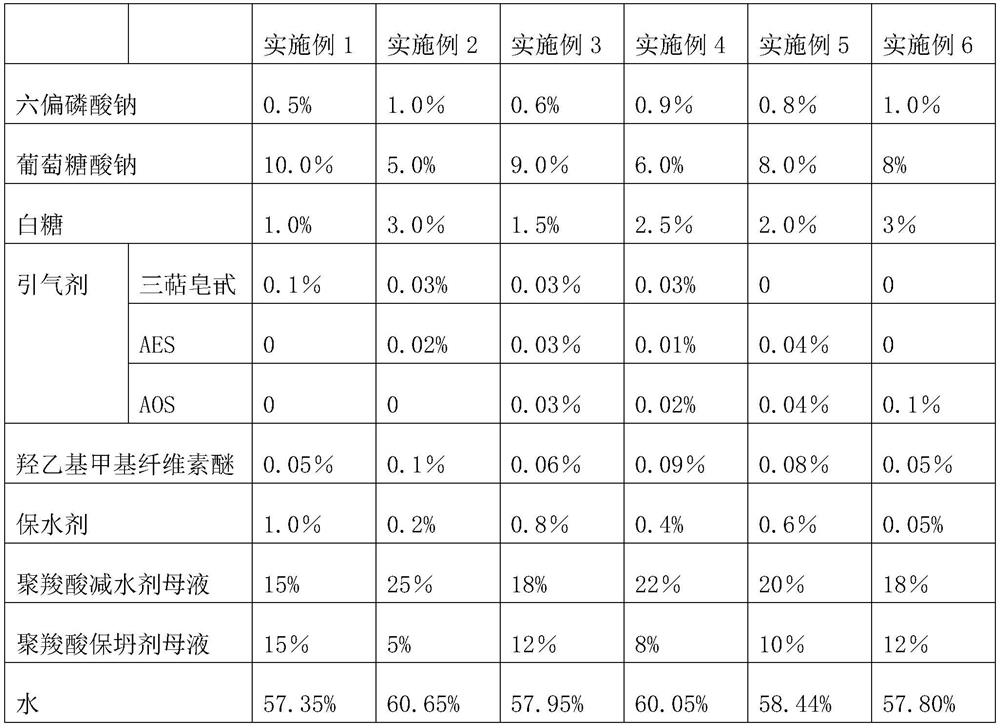

Seventy-two-hour super-slow-setting carboxylic acid pumping agent and preparation method thereof

PendingCN113955972ADoes not affect strengthGuaranteed water reduction rateSodium phosphatesSuperplasticizer

The invention discloses a seventy-two-hour super-slow-setting carboxylic acid pumping agent and a preparation method thereof, and solves the technical problem that the initial setting time of a slow-setting high-performance pumping agent in the prior art is relatively short and cannot meet the construction requirements of secant piles. The pumping agent comprises the following raw materials in percentage by weight: 0.5-1.0% of sodium hexametaphosphate, 5.0%-10.0% of sodium gluconate, 1.0%-3.0% of white sugar, 0.05%-0.1% of an air entraining agent, 0.05%-0.1% of hydroxyethyl methyl cellulose ether, 0.2%-1.0% of a water-retaining agent, 15%-25% of polycarboxylate superplasticizer mother liquor, 5%-15% of polycarboxylic acid slump retaining agent mother liquor, and the balance water. According to the pumping agent disclosed by the invention, on the premise of ensuring the water-reducing rate of concrete, the setting time of the concrete can be prolonged to 72 hours or more, the later strength of the concrete is not influenced, and the requirements of a secant pile construction process are met.

Owner:眉山海螺新材料科技有限公司

An electro-hydraulic throttle salvage tool and its salvage method

ActiveCN111734336BImprove the success rate of salvageLow costBorehole/well accessoriesElectric machineUpper joint

The invention provides an electro-hydraulic choke salvaging tool and a salvaging method, comprising a casing, the top of the casing is an upper joint for cables to pass through, and the casing is encapsulated in order from top to bottom with electronic short joints and hydraulically driven short joints. Joints and self-resetting salvage spear sub-sections, electronic sub-sections are electrically connected with hydraulic driving sub-sections, and hydraulic-driving sub-sections push the self-resetting fishing-spear sub-sections to grab the throttle through hydraulic oil. The motor is controlled by the ground controller, the motor drives the plunger pump, the plunger pump drives the push rod, and the push rod drives the fishing head until the choke is released, which effectively improves the success rate of the downhole choke salvage and can meet the requirements of the downhole choke in the gas field. The safety, reliability and low-cost salvage technology and economic requirements in the process of salvage by flow device.

Owner:PETROCHINA CO LTD

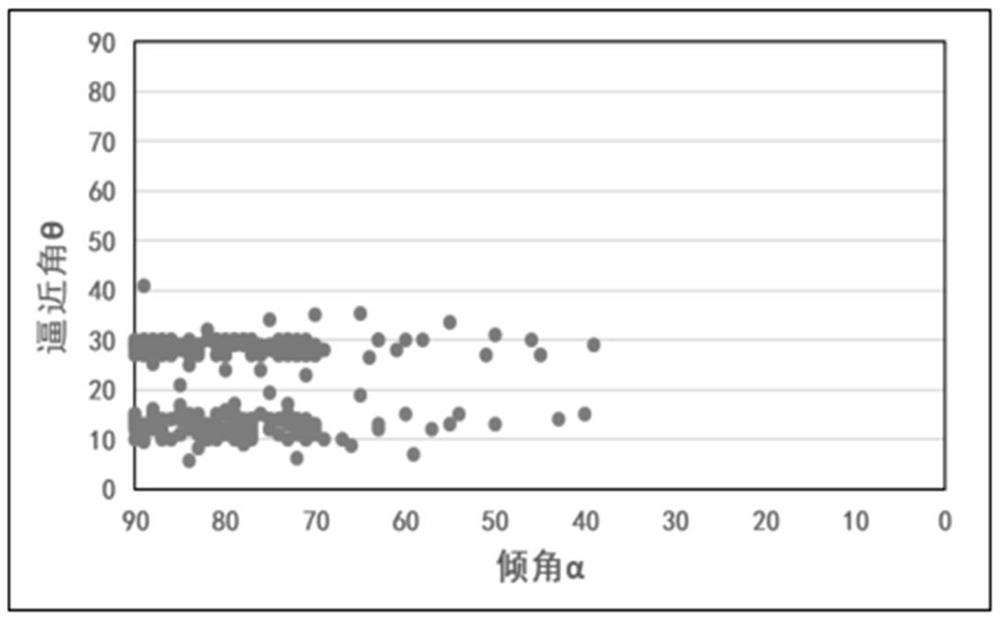

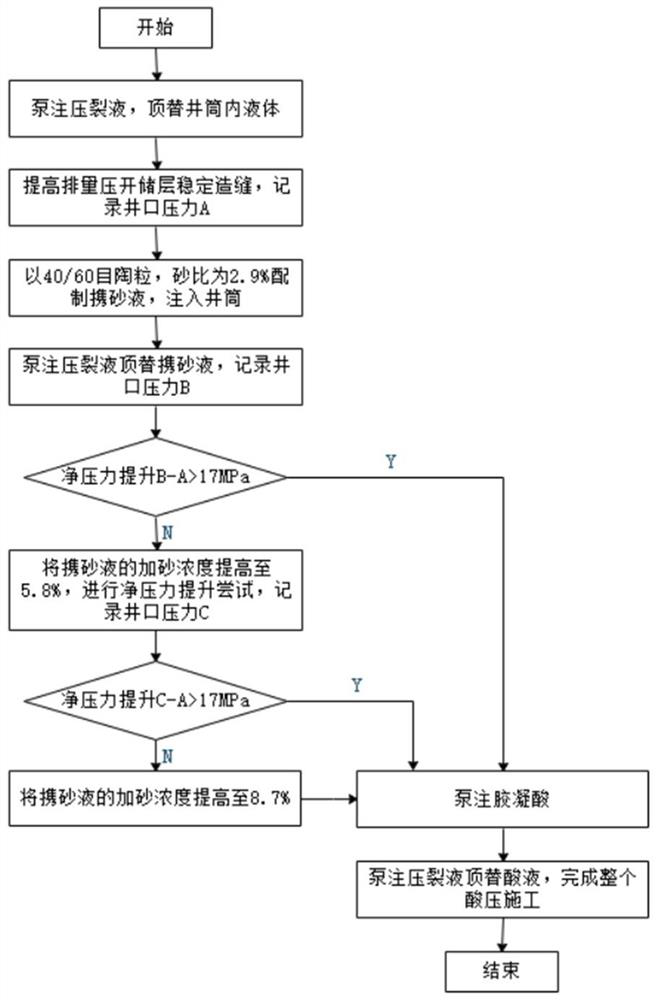

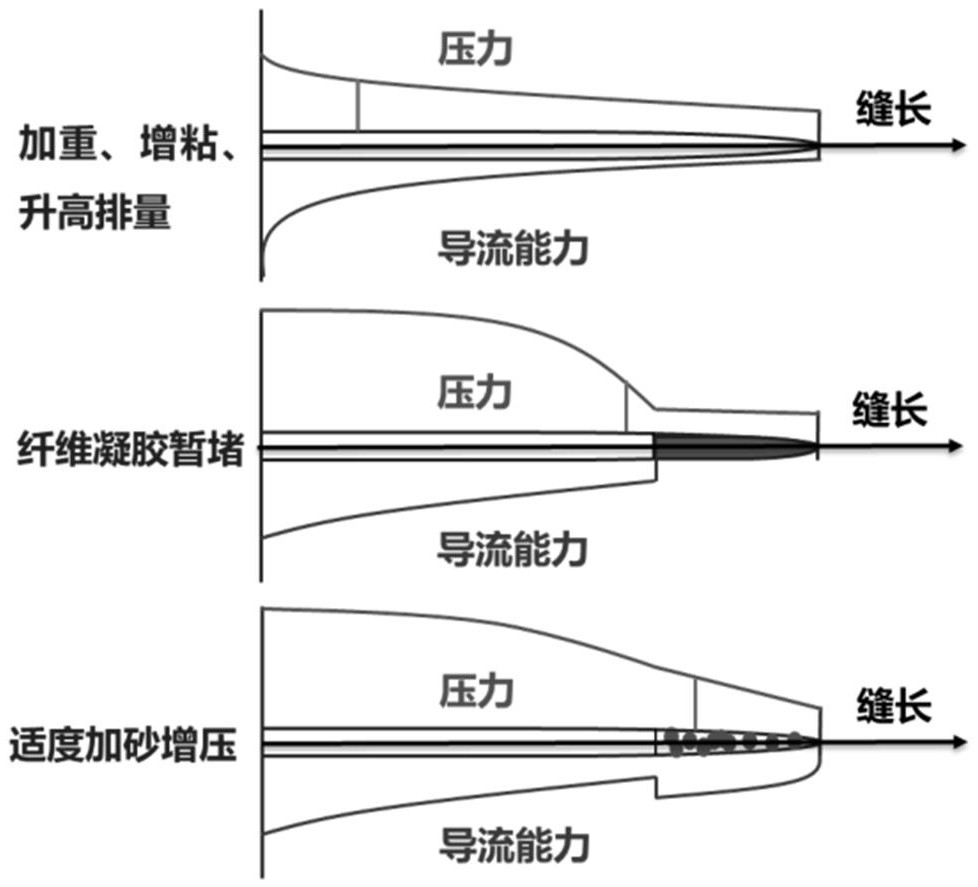

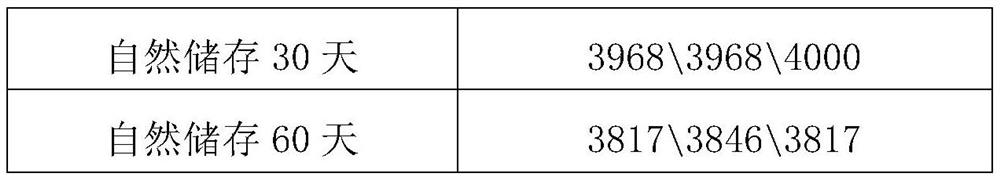

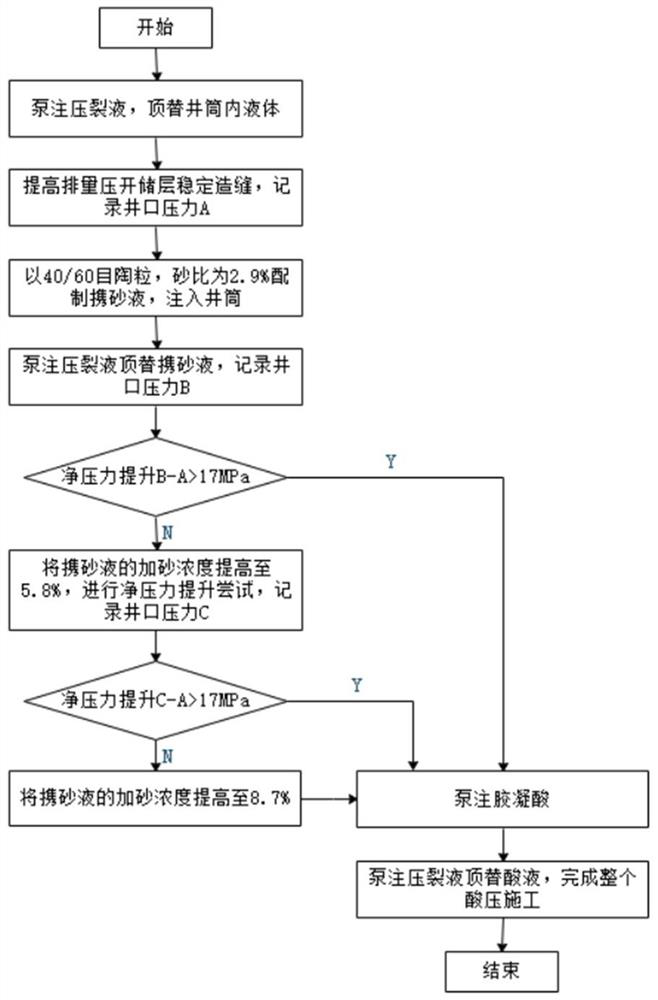

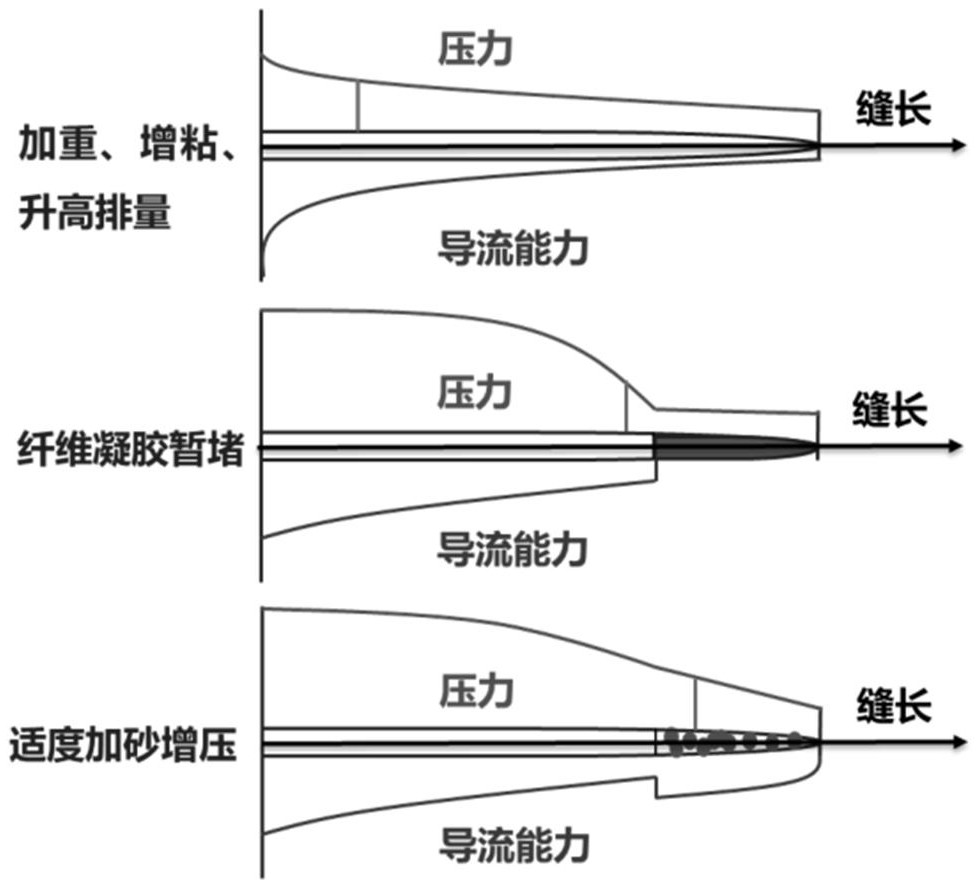

Moderate sand adding, pressurizing and acid fracturing method for improving fracture-vug type reservoir transformation effect

ActiveCN113356826AReduce pumping pressureImprove utilization efficiencyFluid removalAcid etchingAcid fracturing

The invention relates to a moderate sand adding, pressurizing and acid fracturing method for improving the fracture-vug type reservoir transformation effect. The moderate sand adding, pressurizing and acid fracturing method sequentially comprises the following steps of (1) establishing a target reservoir artificial fracture model, calculating to obtain the average fracture width of the artificial fracture model in a reservoir, taking 1 / 3 of the average fracture width as the upper limit value D of the particle size of a propping agent, and measuring the safe sand adding concentration R when the particle size of the propping agent is D; (2) determining a critical net pressure increase value of a natural fracture in the target reservoir with acid fracturing started; and (3) carrying out sand adding, pressurizing and acid fracturing construction on the target reservoir. According to the moderate sand adding, pressurizing and acid fracturing method, based on the characteristic that the net pressure is rapidly increased after sand is added into the fracture-vug type reservoir, a pump injection program is dynamically adjusted, a scheme is optimized in real time, residual acid after acid fracturing and the propping agent are transported to the far end of a fracture together, a near-end acid etching support and a far-end propping agent support are formed, the flow conductivity of a seepage channel in an acid fracturing affecting range is enhanced, the mining efficiency of a fractured-vuggy oil and gas reservoir is improved, and wide market application prospects are achieved.

Owner:SOUTHWEST PETROLEUM UNIV

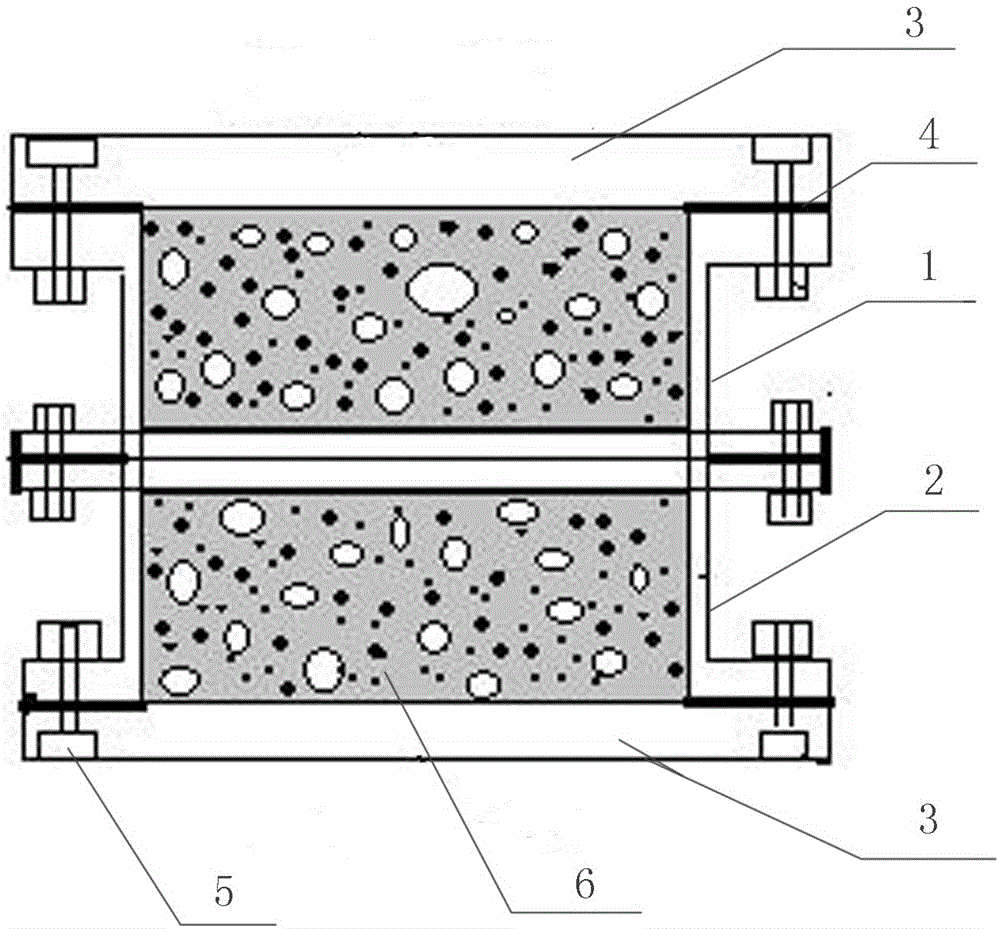

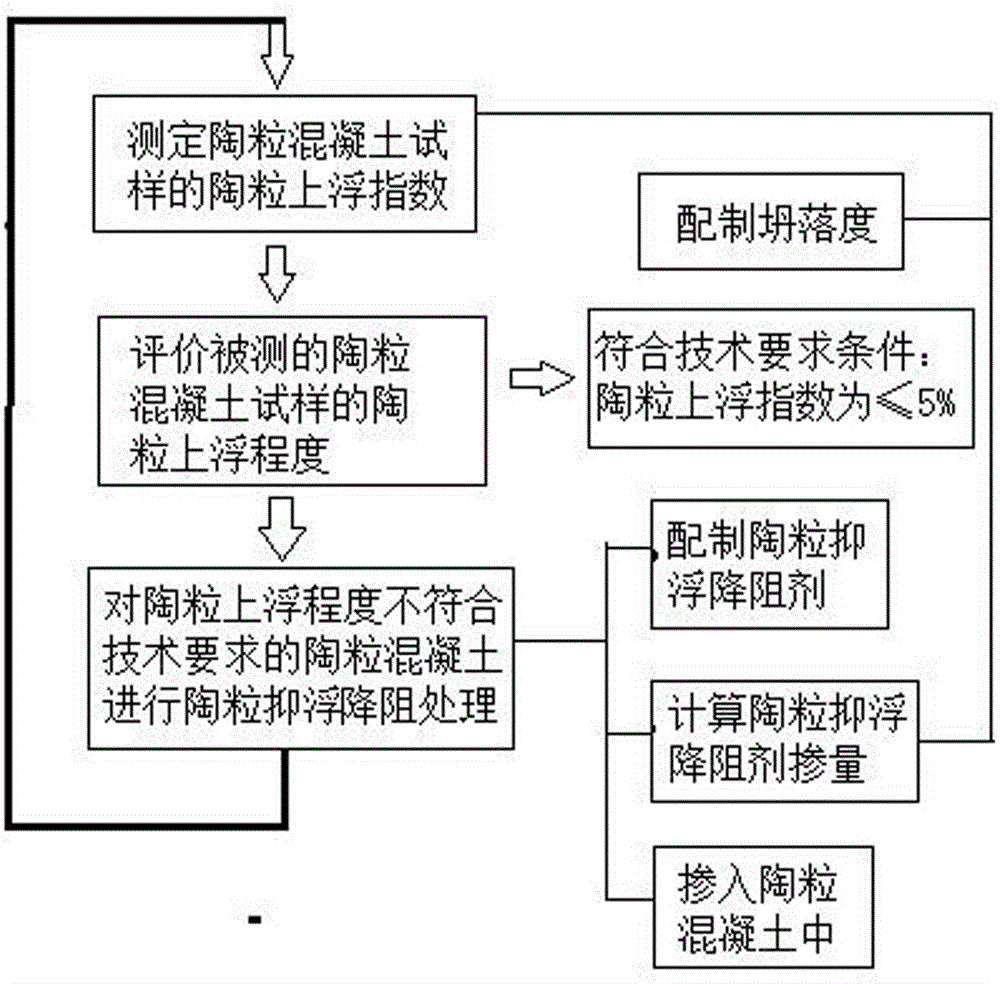

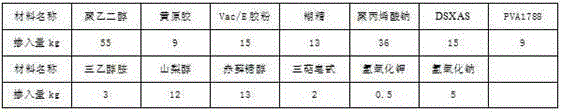

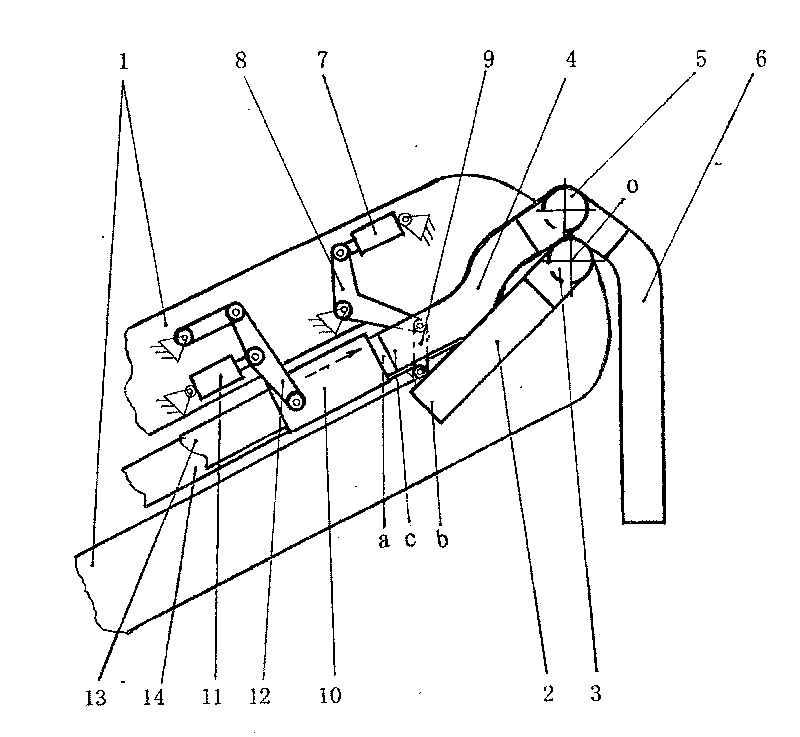

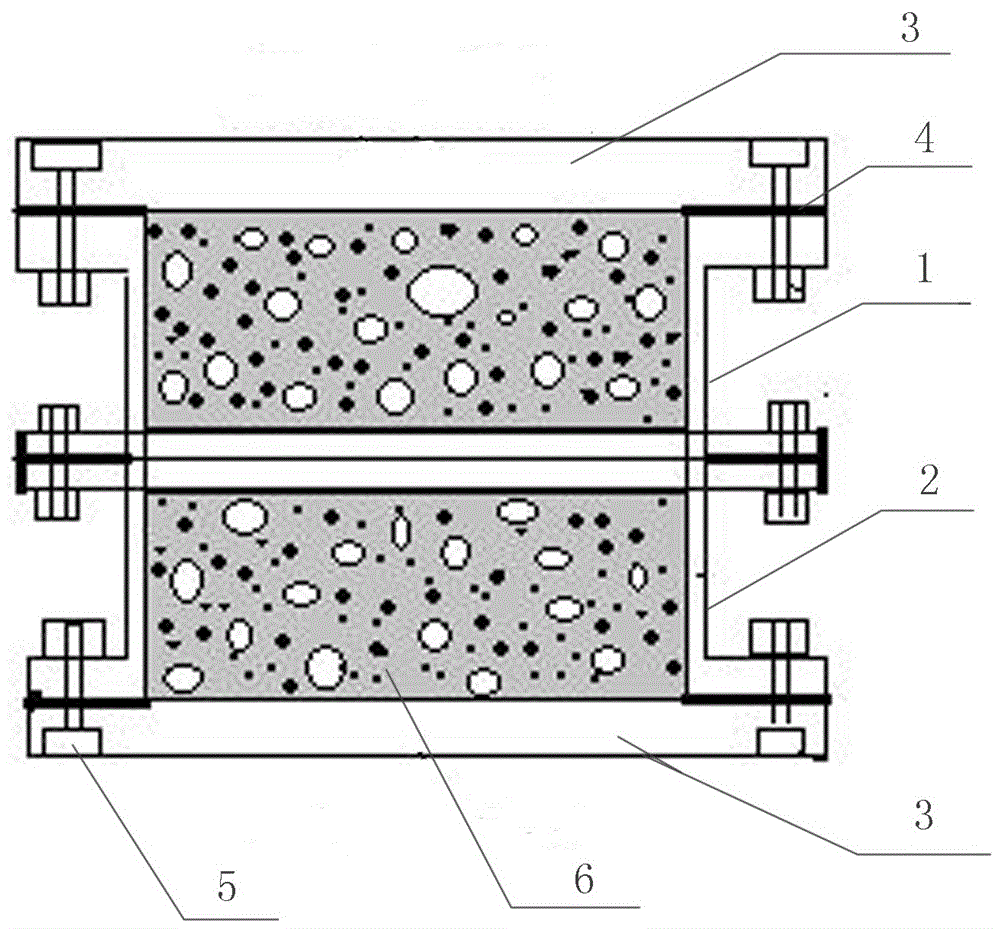

Ceramsite floating restraining and resistance reducing agent and method for reducing floating degree of ceramsite in pumped ceramsite concrete

The invention provides a ceramsite floating restraining and resistance reducing agent and a method for reducing the floating degree of ceramsite in pumped ceramsite concrete. A method for detecting the ceramsite floating index for representing the floating degree of the ceramsite is provided, a reverse vibrating treatment measure and a reverse secondary hitting method are adopted, operation is easy and fast, and the result reliability is high. According to the ceramsite floating restraining and resistance reducing agent and the method applying the ceramsite floating restraining and resistance reducing agent to reducing the floating degree of the ceramsite in the pumped ceramsite concrete, pumping resistance can be effectively lowered, the pumping and lubricating effect can be improved, the pumping speed can be increased, pumping pressure can be lowered, and the percent of the slump of the ceramsite concrete doped with the ceramsite floating restraining and resistance reducing agent to the slump of ceramsite concrete without being doped with the ceramsite floating restraining and resistance reducing agent is not lower than 90%.

Owner:济南四建(集团)有限责任公司

A kind of concrete admixture mainly composed of marble powder and reducing bleeding type and preparation method thereof

The invention relates to the field of building materials, in particular to a bleeding-reducing concrete admixture mainly composed of marble stone powder and a preparation method thereof, comprising the following components in parts by weight: 50-70 parts of modified marble stone powder, superfine powder 10-20 parts of coal ash, 10-20 parts of silica fume, and 1-5 parts of water-retaining agent. The preparation method is to add water-retaining agent and silica fume to the mixer at the same time and stir for 10-20 minutes, then add ultra-fine fly ash, Stir for 10-20 minutes, finally add modified marble stone powder and stir for 20-30 minutes, and mix uniformly to prepare the bleeding-reducing concrete admixture. The present invention introduces modified marble stone powder, superfine fly ash, and silica fume and optimizes them to increase the flow rate of concrete and improve pumping performance, and at the same time introduces water-retaining agent to improve the homogeneity of concrete, reduce bleeding of concrete and improve concrete Homogeneity, can be widely used in the construction of pumped concrete, medium and low grade concrete.

Owner:FUJIAN KZJ NEW MATERIALS CO LTD

A high pressure washer

The invention discloses a high-pressure washer which has the advantage of avoiding too high instantaneous water pressure so as not cause damage when a spray pipe is closed. According to the technicalscheme, a water inlet and a water outlet are formed in a high-pressure plunger pump, and a valve device is arranged on the high-pressure plunger pump. The valve device comprises a valve body and a flow limiting valve plate, and the valve body is fixedly connected with one end, close to the water outlet, of the high-pressure plunger pump. A valve chamber is formed in the valve body, and the two ends of the valve chamber are respectively connected with a connecting pipe and the water outlet. The flow limiting valve plate is arranged in the valve chamber. A cushioning cylinder body is arranged onthe valve body, and a sealed piston is arranged in the cushioning cylinder body. A connecting rod connected with the flow limiting valve plate is arranged at one end, close to the valve chamber, of the sealed piston, and the other end of the cushioning cylinder body communicates with the connecting pipe. An elastic reset piece for enabling the sealed piston to move to one end far away from the valve body is arranged on the cushioning cylinder body. A flow limiting hole is formed in the flow limiting valve plate, and the section of the flow limiting hole is trapezoidal. The two ends of the trapezoidal flow limiting hole are respectively a large bottom surface and a small bottom surface, and the small bottom surface end of the flow limiting hole is close to the cushioning cylinder body.

Owner:南京汇涛节能科技有限公司

A sand-free fracturing fluid with high conductivity, its preparation method, fracturing technology and application

ActiveCN108315005BSolve the problem of frequent sand pluggingThere will be no sand pluggingDrilling compositionFiberFracturing fluid

Owner:PEKING UNIV

Device and method for continuously injecting hot seawater to exploit seabed natural gas hydrate

ActiveCN104912532BGet in placeLow costConstructionsFluid removalPressure transmissionCommunicating vessels

Owner:INST OF MECHANICS CHINESE ACAD OF SCI

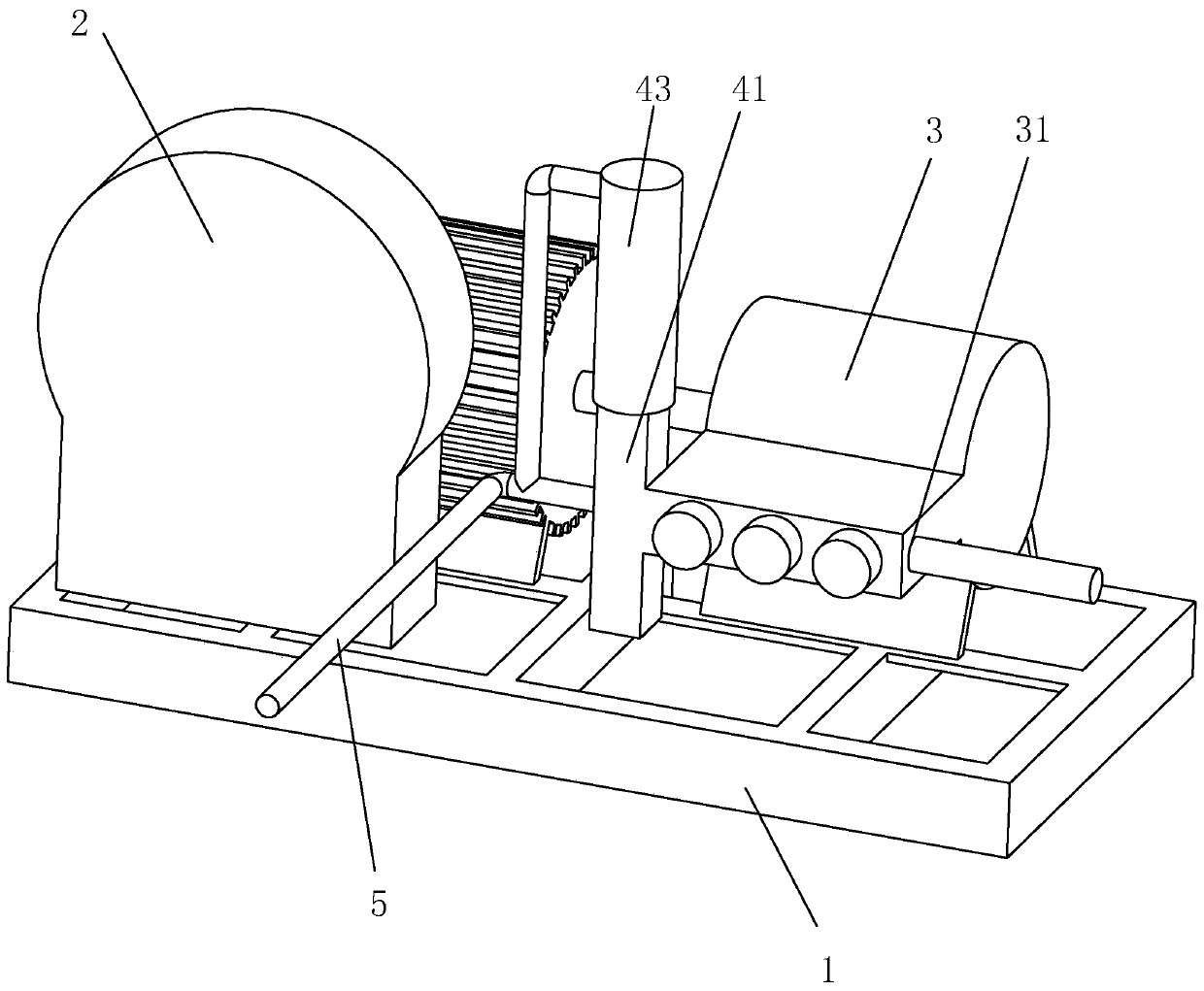

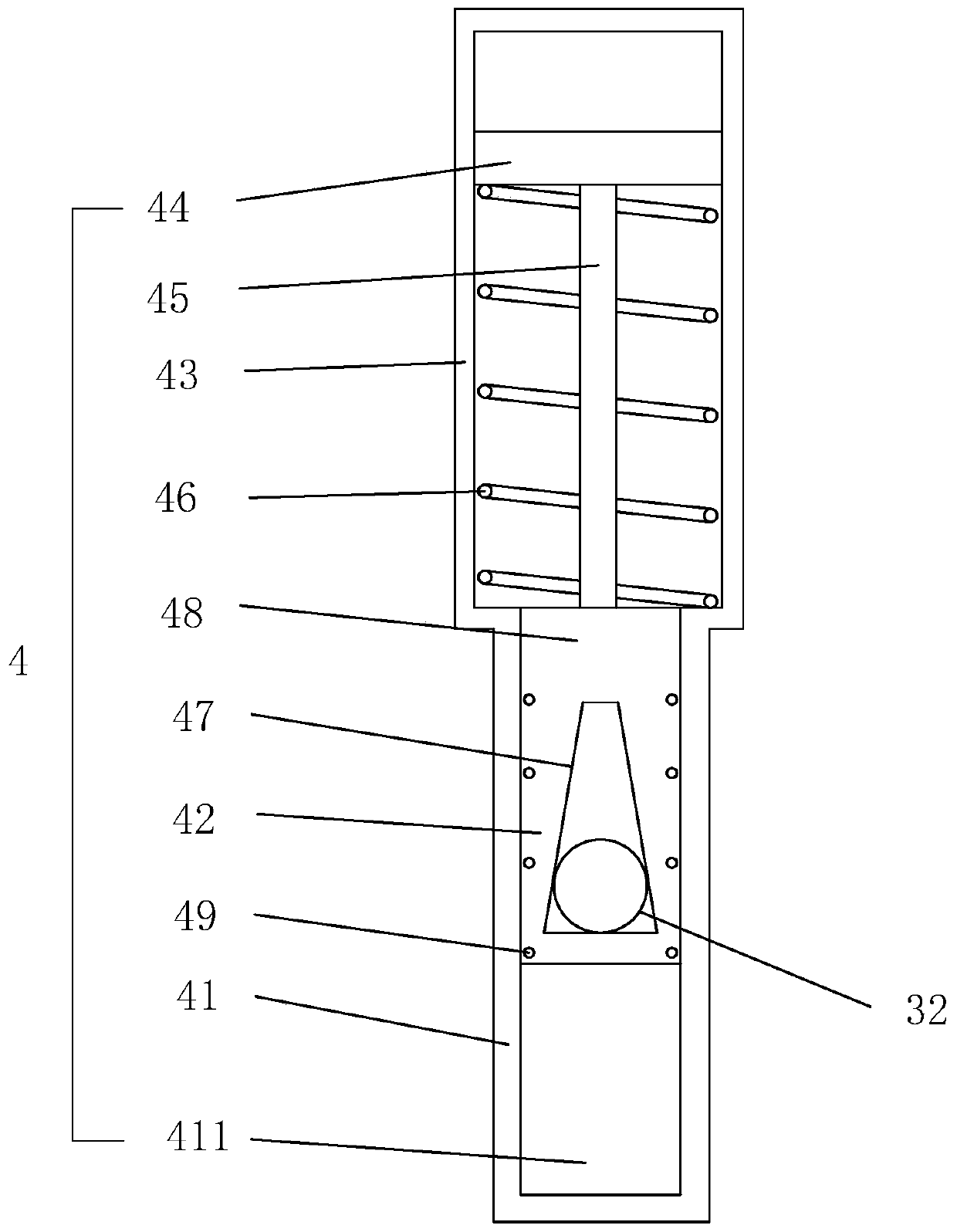

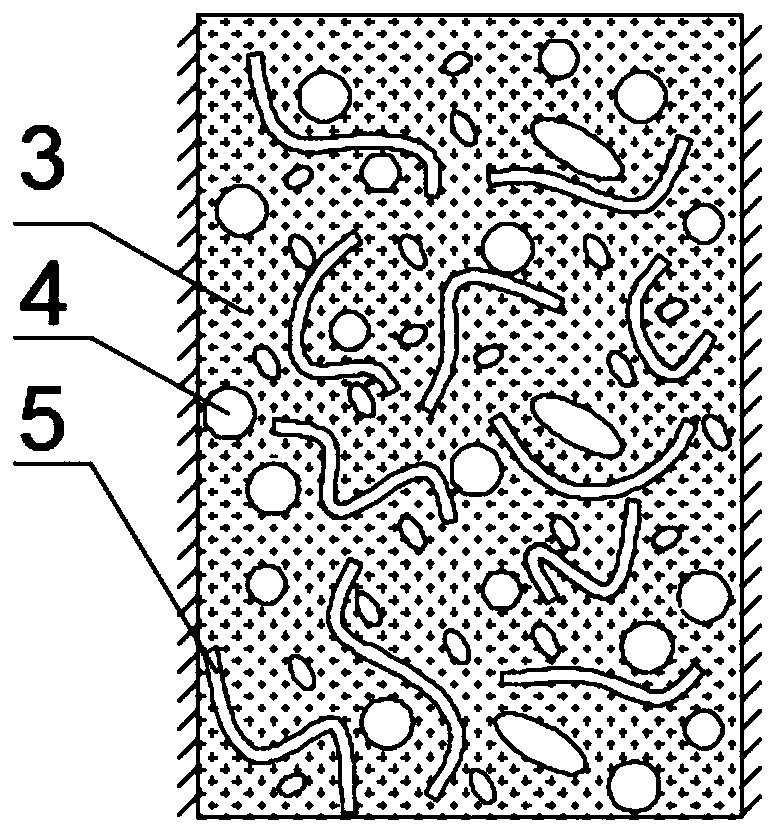

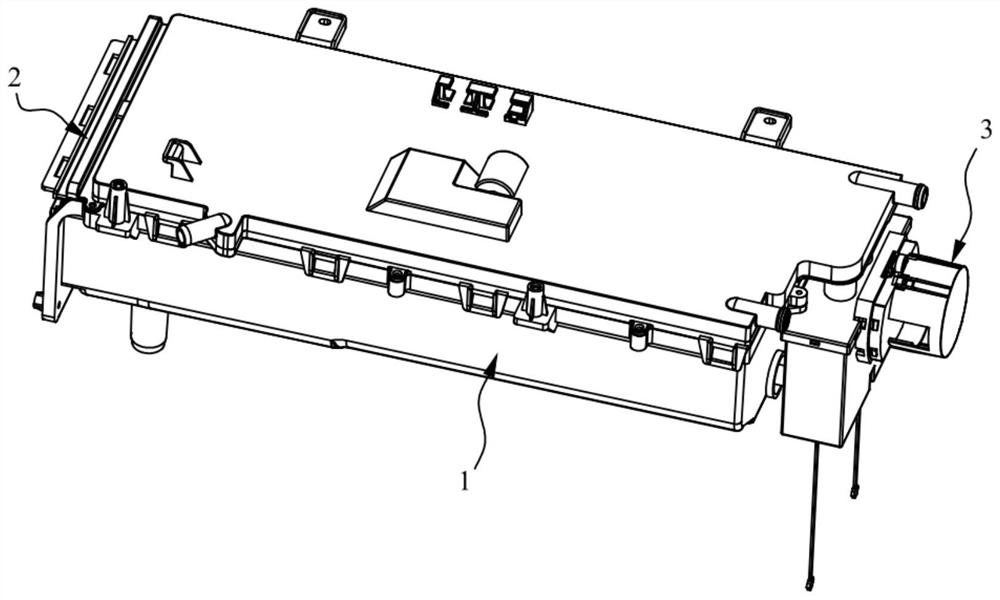

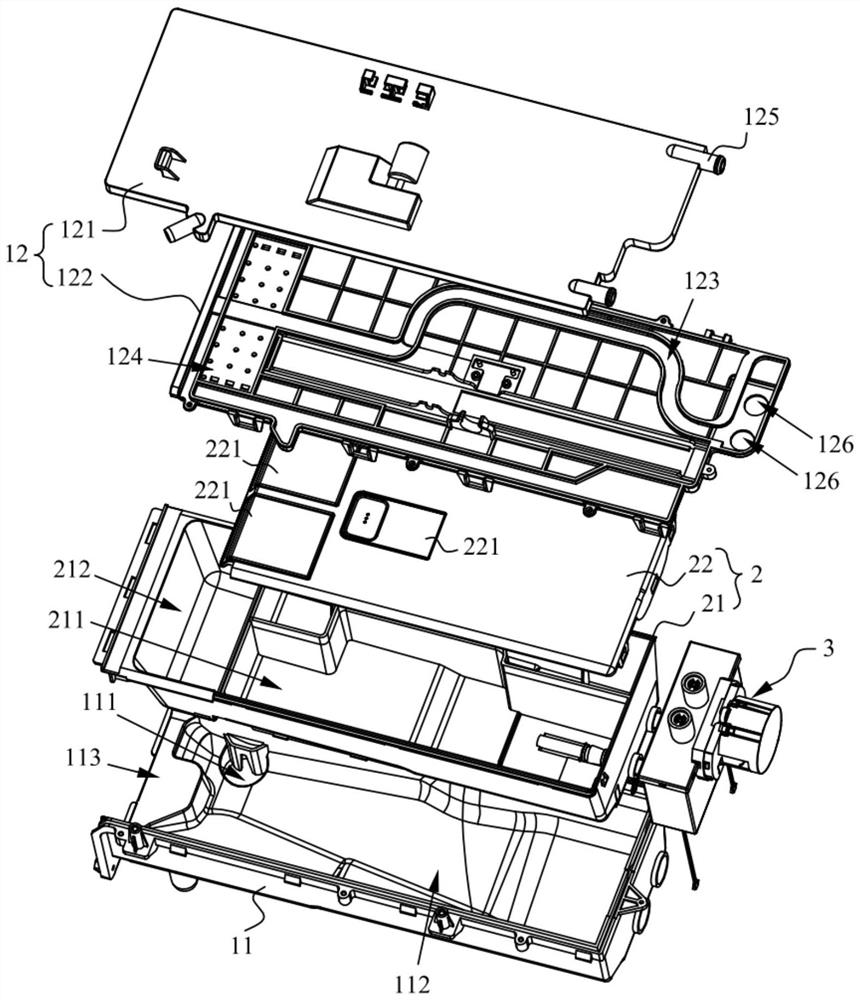

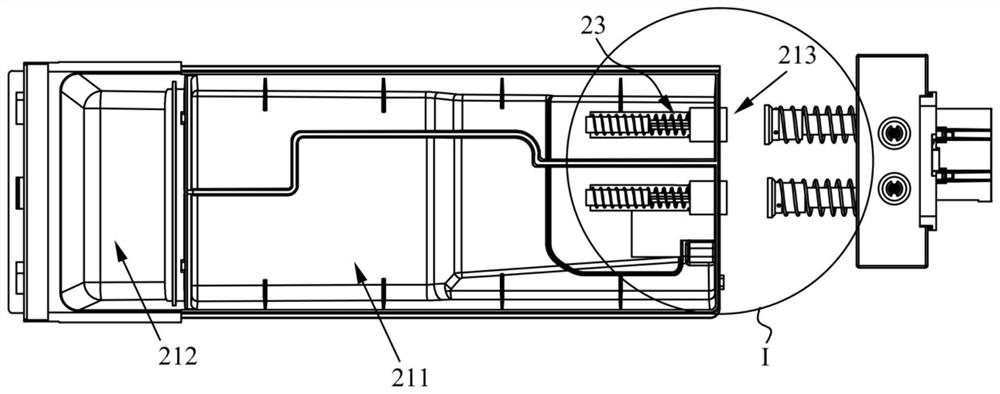

Automatic putting device and washing machine

ActiveCN114197173ASimple structureLow costOther washing machinesTextiles and paperLaundry washing machineProcess engineering

The invention belongs to the technical field of washing machines, and particularly discloses an automatic putting device and a washing machine. The automatic feeding device comprises a distribution box, the distribution box is provided with at least one liquid storage cavity, a liquid outlet is formed in the bottom of the side wall of one end of the distribution box, and the liquid outlet is communicated with the liquid storage cavity; the pumping unit is arranged at one end of the distribution box, and the pumping unit comprises a liquid suction pipe arranged at the bottom of the pumping unit; when the distribution box is separated from the pumping unit, the liquid outlet is sealed by the unsealing assembly, and when the distribution box is matched with the pumping unit in place, the unsealing assembly is far away from the liquid outlet, and the liquid suction pipe extends into the liquid storage cavity in a sealed mode to be communicated with the liquid storage cavity. The washing machine comprises the automatic putting device. According to the automatic putting device and the washing machine, the structure of the automatic putting device is simplified, and the cost of the automatic putting device and the washing machine is reduced.

Owner:NANJING ZHONGJINGKE ELECTRONICS TECH

Automatic shearing filter screen device applied to emulsion conveying pipeline in fracturing construction

InactiveCN113828030AReduce viscosity valueReduce pumping pressureDispersed particle filtrationFluid removalControl engineeringFracturing fluid

The invention discloses an automatic shearing filter screen device applied to an emulsion conveying pipeline in fracturing construction, and belongs to the field of oil and gas field development. The automatic shearing filter screen device applied to the emulsion conveying pipeline in fracturing construction comprises a main pipe assembly and a filter box communicating with one end of the main pipe assembly, a filter screen is fixedly installed at the joint of the interior of the filter box and the main pipe assembly, a pressure sensor and a speed sensor are arranged in the main pipe assembly, the end, away from the main pipe assembly, of the filter box communicates with a feeding pipe, and two sets of shearing blades are symmetrically arranged on the side, connected with the main pipe assembly, of the interior of the filter box. The minimum distance between the shearing blades and the filter screen is 1mm. The device can realize and reduce the viscosity value of fracturing fluid in the main pipe assembly, and the fracturing fluid can conveniently pass through the filter screen, so that the pumping pressure of the fracturing fluid in the main pipe assembly is reduced, the condition that the interior of the filter box is blocked is reduced, and the condition that the pumping of emulsion is forced to be interrupted is prevented.

Owner:北京中海沃邦能源投资有限公司

A kind of oil phase for emulsified explosive of high-temperature sensitization process prepared by using coal-to-oil intermediate product and its preparation method

ActiveCN112919998BImprove liquidityReduce pumping pressureNon-explosive stabilisersExplosive AgentsActive agent

Owner:GEZHOUBA YIPULI HUBEI CHANGTAI CIVIL EXPLOSIVE

Method for selecting arm support accroding to the pumping distance in concrete pump vehicle

InactiveCN101078298BImprove job stabilityImprove construction efficiencyBuilding material handlingArchitectural engineeringStructural engineering

The invention provides a method for pumping concrete in concrete pump truck and the device. The pumping distance of prior concrete pump truck in most construction occasions is not big but only one discharge port is set at the end of fitting pipe of arm frame in the arm frame with several decameters. So in construction all arm frames must be unfolded and by adopting high-pressure pumping, concretepasses through all fitting pipes of arm frame. Not only power is consumed and abrasion is enlarged but also efficiency and stability are decreased. Aiming at the lack of concrete pump truck existing in pumping work process, the invention provides that concrete assistant discharge device is set on the arm frame of concrete pump truck; according to the construction distance of pumping concrete fitting pipes of arm frame is switched and all or part fitting pipes of arm frame are selected to carry the construction operation of pumping concrete out. The invention can unfold proper arm frame according to the requirement and make use of corresponding fitting pipe of arm frame to construct work of pumping concrete so as to achieve purposes that the pumping pressure is decreased; energy consumptionis decreased; pipe abrasion is decreased; work efficiency and stability of pumping operation are improved.

Owner:董连城

A kind of ceramsite buoyancy suppression agent and method for reducing ceramsite floating degree in pumped ceramsite concrete

ActiveCN105036597BGuaranteed accuracyEasy to operateMaterial analysisEngineeringMechanical engineering

The invention provides a ceramsite floating restraining and resistance reducing agent and a method for reducing the floating degree of ceramsite in pumped ceramsite concrete. A method for detecting the ceramsite floating index for representing the floating degree of the ceramsite is provided, a reverse vibrating treatment measure and a reverse secondary hitting method are adopted, operation is easy and fast, and the result reliability is high. According to the ceramsite floating restraining and resistance reducing agent and the method applying the ceramsite floating restraining and resistance reducing agent to reducing the floating degree of the ceramsite in the pumped ceramsite concrete, pumping resistance can be effectively lowered, the pumping and lubricating effect can be improved, the pumping speed can be increased, pumping pressure can be lowered, and the percent of the slump of the ceramsite concrete doped with the ceramsite floating restraining and resistance reducing agent to the slump of ceramsite concrete without being doped with the ceramsite floating restraining and resistance reducing agent is not lower than 90%.

Owner:济南四建(集团)有限责任公司

Oil phase prepared from coal-to-oil intermediate product for high-temperature sensitization process emulsion explosive and preparation method of oil phase

The invention discloses an oil phase prepared from a coal-to-oil intermediate product for high-temperature sensitization process emulsion explosive and a preparation method of the oil phase. The oil phase is composed of the coal-to-oil intermediate product, a wax material, an SP-80 emulsifier and a polymer surfactant according to a weight ratio of (50-55):(12-17):(18-22):(5-10). The four materials are metered and added into a mixing tank to be heated, stirred and mixed for 40-70 min, the temperature is controlled to be 75+ / -5 DEG C, and mixing is carried out to form the compound oil phase; and the coal-to-oil intermediate product is a semi-finished product in the coal-to-oil production process, namely a coal-to-oil intermediate product. The invention has the advantages that: no other oil phase material is added, various performance indexes of the produced emulsion explosive can completely reach the national standard, and the product has the advantages of good fluidity, low pumping pressure and the like. The composite oil phase has the advantages of higher calorific value, favorable safety performance, convenience in use, low price, wide sources of various raw materials and higher economic benefit.

Owner:GEZHOUBA YIPULI HUBEI CHANGTAI CIVIL EXPLOSIVE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com