Automatic shearing filter screen device applied to emulsion conveying pipeline in fracturing construction

A technology for conveying pipelines and construction, applied in the field of automatic shearing screen devices, can solve problems such as the drop of pumping pressure and the viscosity value of fracturing fluid, so as to reduce clogging, reduce waste of resources, and be beneficial to the construction environment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

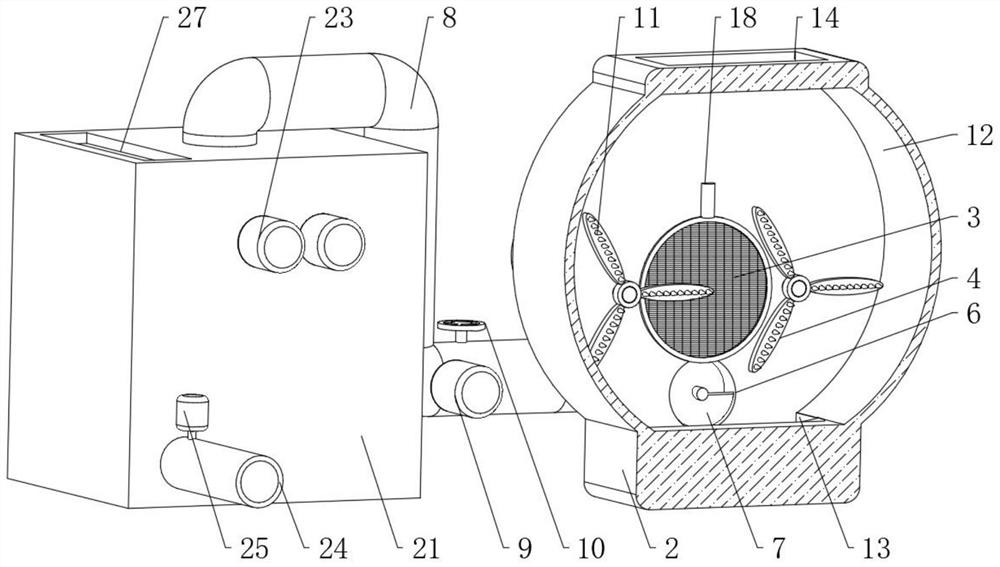

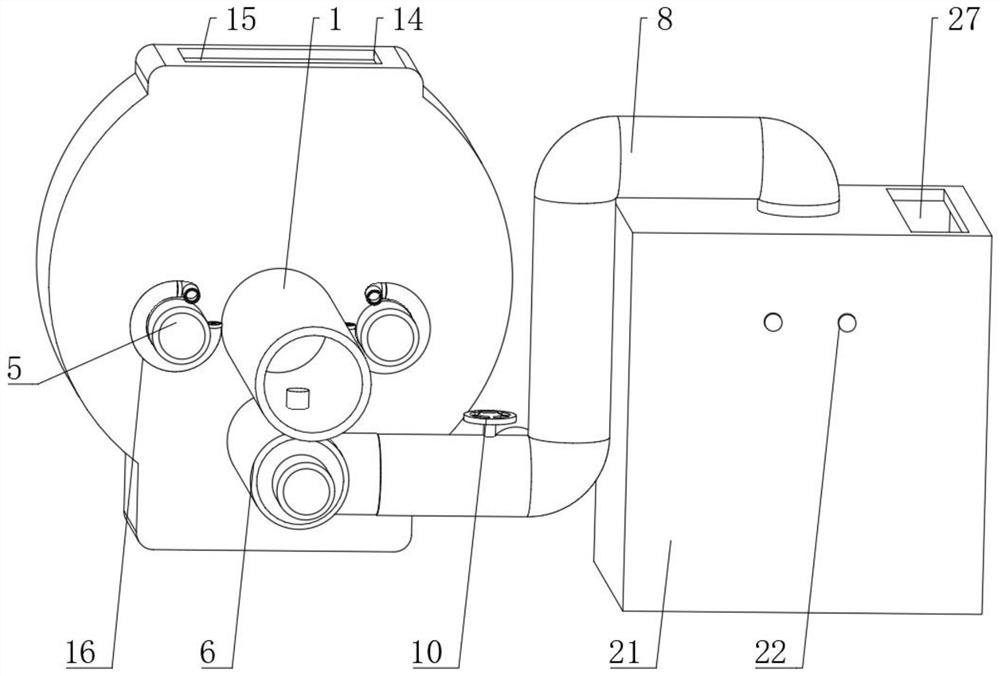

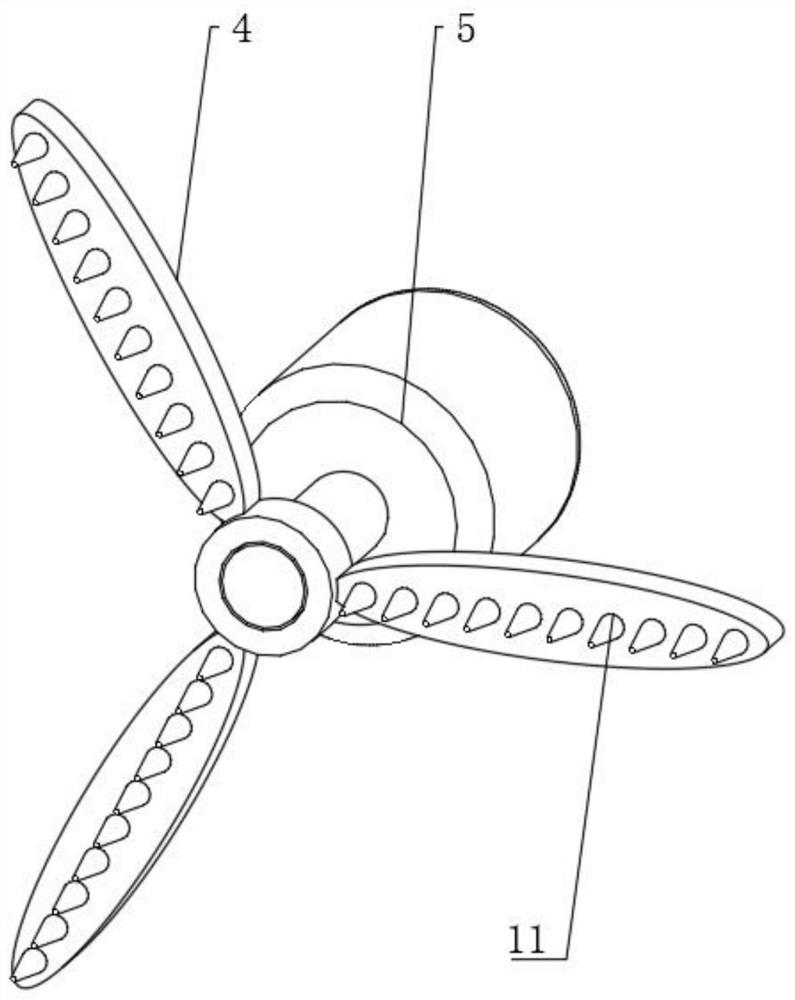

[0036] see Figure 1-7 , an automatic shearing filter screen device used in emulsion delivery pipelines in fracturing construction, including a main pipe assembly 1 and a filter box 2 connected to one end of the main pipe assembly 1, and also includes a computer, the inside of the filter box 2 and the main pipe assembly 1 A filter screen 3 is fixedly installed at the joint, and a pressure sensor and a speed sensor are installed inside the main pipe assembly 1. The end of the filter box 2 away from the main pipe assembly 1 is connected to a feed pipe, and a booster pump is provided on the side of the feed pipe. This scheme It is a prior art, not shown in the figure. When working, a filter screen 3 with a specified pore size is installed in the filter box 2, so that the connection between the inside of the filter box 2 and the main pipe assembly 1 is covered, and the fracturing fluid is pressurized Pushed by the pump, it flows into the main pipe assembly 1 along the feed pipe an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com