Oil phase prepared from coal-to-oil intermediate product for high-temperature sensitization process emulsion explosive and preparation method of oil phase

An emulsion explosive and coal-to-liquid technology, which is applied in the directions of explosives, non-explosive stabilizers, non-explosive/non-thermal components, etc., can solve the problems of high price of petroleum by-products, fluctuations in the quality of oil-phase materials, and waste of resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

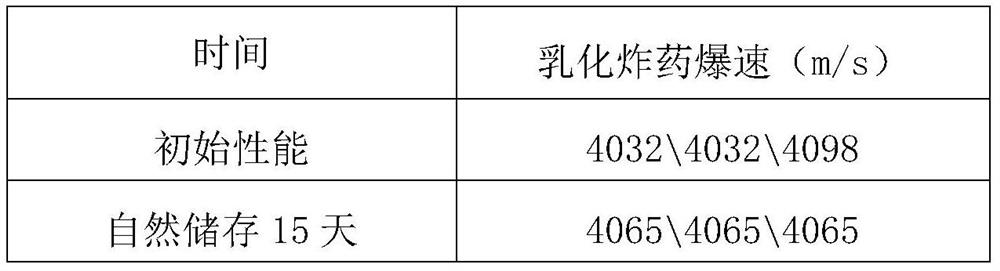

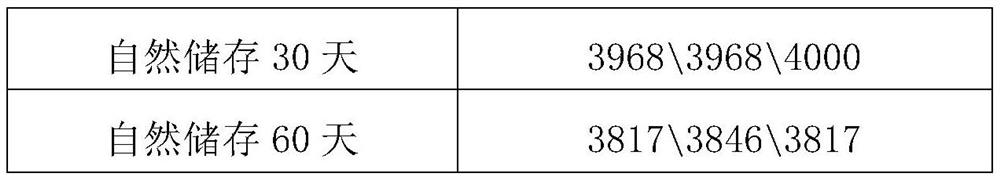

[0015] A method for preparing an oil phase for high-temperature sensitized emulsion explosives by using coal-to-oil intermediate products, comprising mixing coal-to-oil intermediate products, wax materials, sp-80 emulsifiers, and polymer surfactants, the weight ratio of the four materials being 50-55:12-17:18-22:5-10, the four kinds of materials are added into the mixing tank by metering, heated and stirred for 40-70min, and the temperature is controlled at 75±5°C to form a composite oil phase, coal-to-oil The intermediate product is composed of linear hydrocarbons and oxygenated organic compounds, and is a semi-finished product in the process of coal-to-oil production.

[0016] The coal-to-liquid intermediate product is a coal chemical technology that uses coal as raw material to produce liquid fuel and chemical raw materials. The index of the coal-to-liquid intermediate product is 100°C kinematic viscosity of 10-14mm 2 / s, 20°C density 800-900kg / m 3 , freezing point 0-15°C, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Solidifying point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com