Seventy-two-hour super-slow-setting carboxylic acid pumping agent and preparation method thereof

A slow coagulation carboxylic acid and pumping agent technology, which is applied in the field of concrete admixtures, can solve problems such as short initial setting time and cannot meet the construction requirements of occlusal piles, and achieve the purpose of inhibiting cement hydration reaction, enhancing slump performance, and reducing time-lapse loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

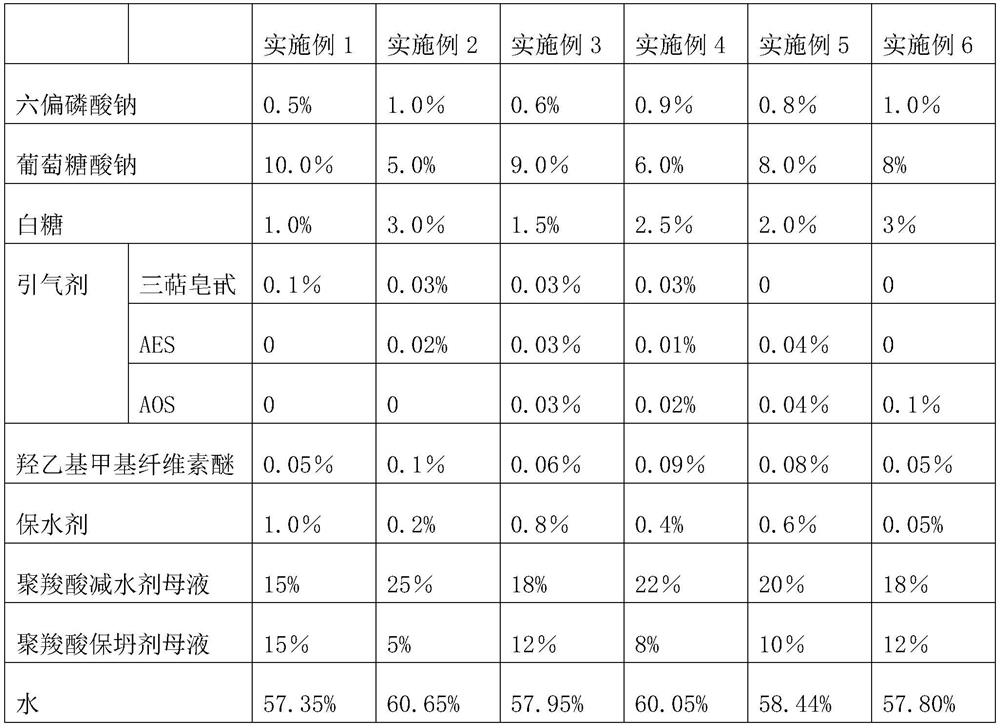

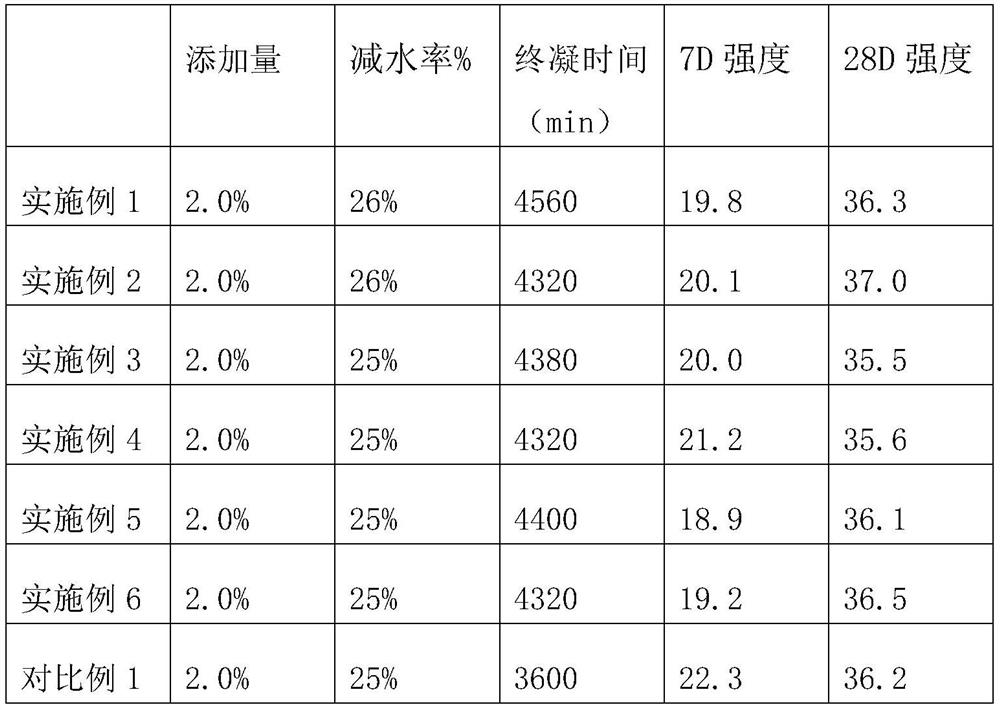

Embodiment 1

[0062] Include the following steps:

[0063] S1. Weigh sodium hexametaphosphate, sodium gluconate, sugar, air-entraining agent, hydroxyethyl methyl cellulose ether, water retaining agent, polycarboxylate water reducer mother liquor, polycarboxylate slump retaining agent mother liquor and water according to the ratio ;

[0064] S2, adding water into the reaction vessel;

[0065] S3, start stirring and keep stirring state (stirring speed is 1000r / min), add sodium hexametaphosphate, sodium gluconate and white sugar in reaction vessel; Then stir for 15min;

[0066] S4, keep stirring state (stirring speed is 1000r / min), add air-entraining agent in reaction vessel, then stir 15min;

[0067] S5, keep stirring state (stirring speed is 1000r / min), add polycarboxylate superplasticizer mother liquor, polycarboxylate slump retaining agent mother liquor in reaction vessel, stir 15min;

[0068] S6. Keep stirring (stirring speed is 1000r / min), add water retaining agent and hydroxyethyl ce...

Embodiment 2

[0070] Include the following steps:

[0071] S1. Weigh sodium hexametaphosphate, sodium gluconate, sugar, air-entraining agent, hydroxyethyl methyl cellulose ether, water retaining agent, polycarboxylate water reducer mother liquor, polycarboxylate slump retaining agent mother liquor and water according to the ratio ;

[0072] S2, adding water into the reaction vessel;

[0073] S3, start stirring and keep stirring state (stirring speed is 1200r / min), add sodium hexametaphosphate, sodium gluconate and white sugar in reaction vessel; Then stir for 10min;

[0074] S4, keep stirring state (stirring speed is 1200r / min), add air-entraining agent in reaction vessel, then stir 10min;

[0075] S5, keep stirring state (stirring speed is 1200r / min), add polycarboxylate superplasticizer mother liquor, polycarboxylate slump retaining agent mother liquor in reaction vessel, stir 10min;

[0076] S6. Keep stirring (stirring speed is 1200r / min), add water retaining agent and hydroxyethyl cell...

Embodiment 3

[0078] Include the following steps:

[0079] S1. Weigh sodium hexametaphosphate, sodium gluconate, sugar, air-entraining agent, hydroxyethyl methyl cellulose ether, water retaining agent, polycarboxylate water reducer mother liquor, polycarboxylate slump retaining agent mother liquor and water according to the ratio ;

[0080] S2, adding water into the reaction vessel;

[0081] S3, start stirring and keep stirring state (stirring speed is 800r / min), add sodium hexametaphosphate, sodium gluconate and white sugar in reaction vessel; Then stir for 20min;

[0082] S4, keep stirring state (stirring speed is 800r / min), add air-entraining agent in reaction vessel, then stir 20min;

[0083] S5, keep stirring state (stirring speed is 800r / min), add polycarboxylate superplasticizer mother liquor, polycarboxylate slump retaining agent mother liquor in reaction vessel, stir 20min;

[0084] S6. Keep stirring (stirring speed is 800r / min), add water retaining agent and hydroxyethyl cellul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com