Temperature-sensitive plugging cement paste for oil well cementation and preparation method of temperature-sensitive plugging cement paste

A mud and oil well technology, which is applied in the field of oil well cementing temperature-sensitive plugging cement slurry and its preparation, can solve the problems of low cement strength and no temperature-sensitive plugging, and achieve low pumping pressure and good plugging The effect, the effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

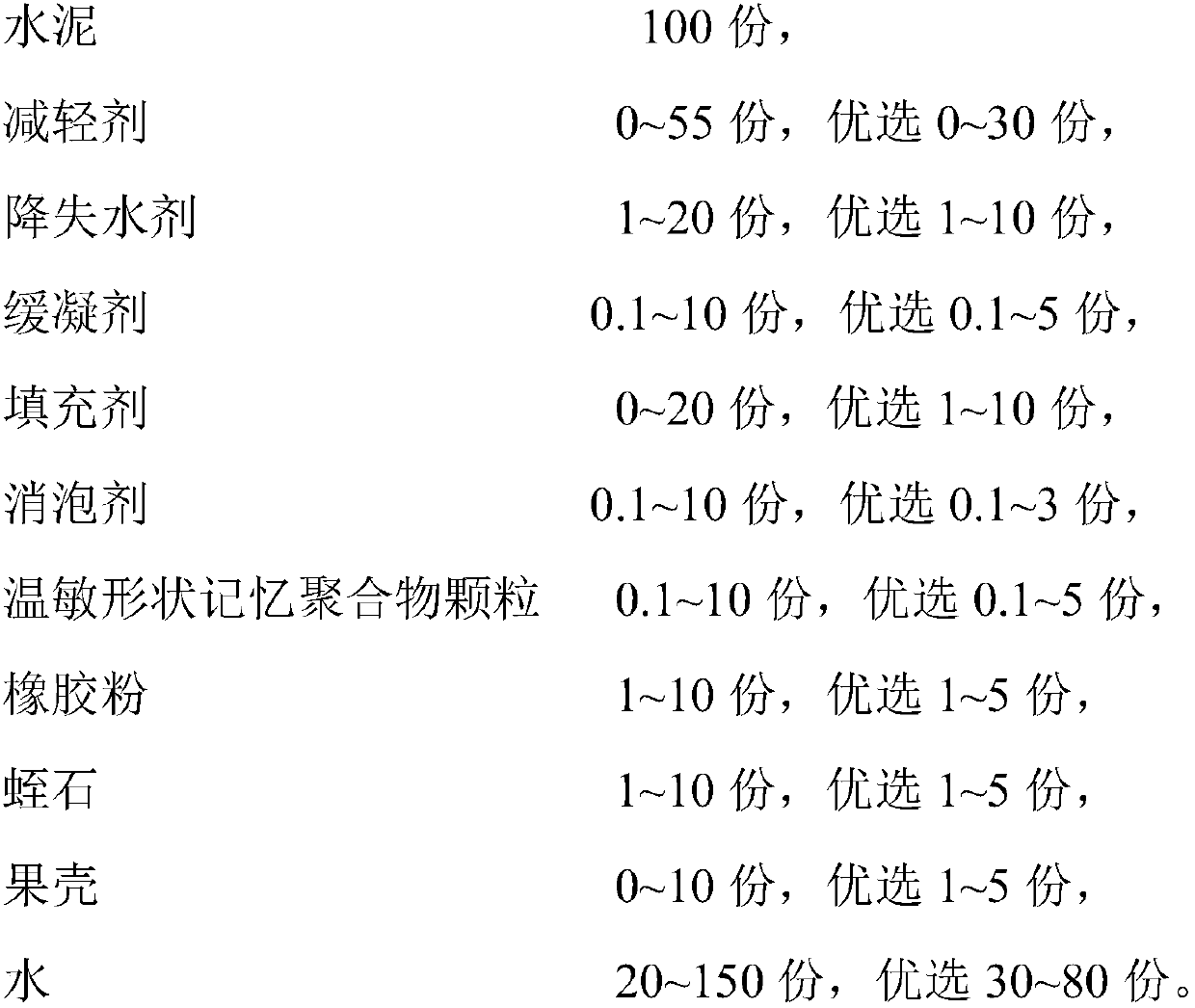

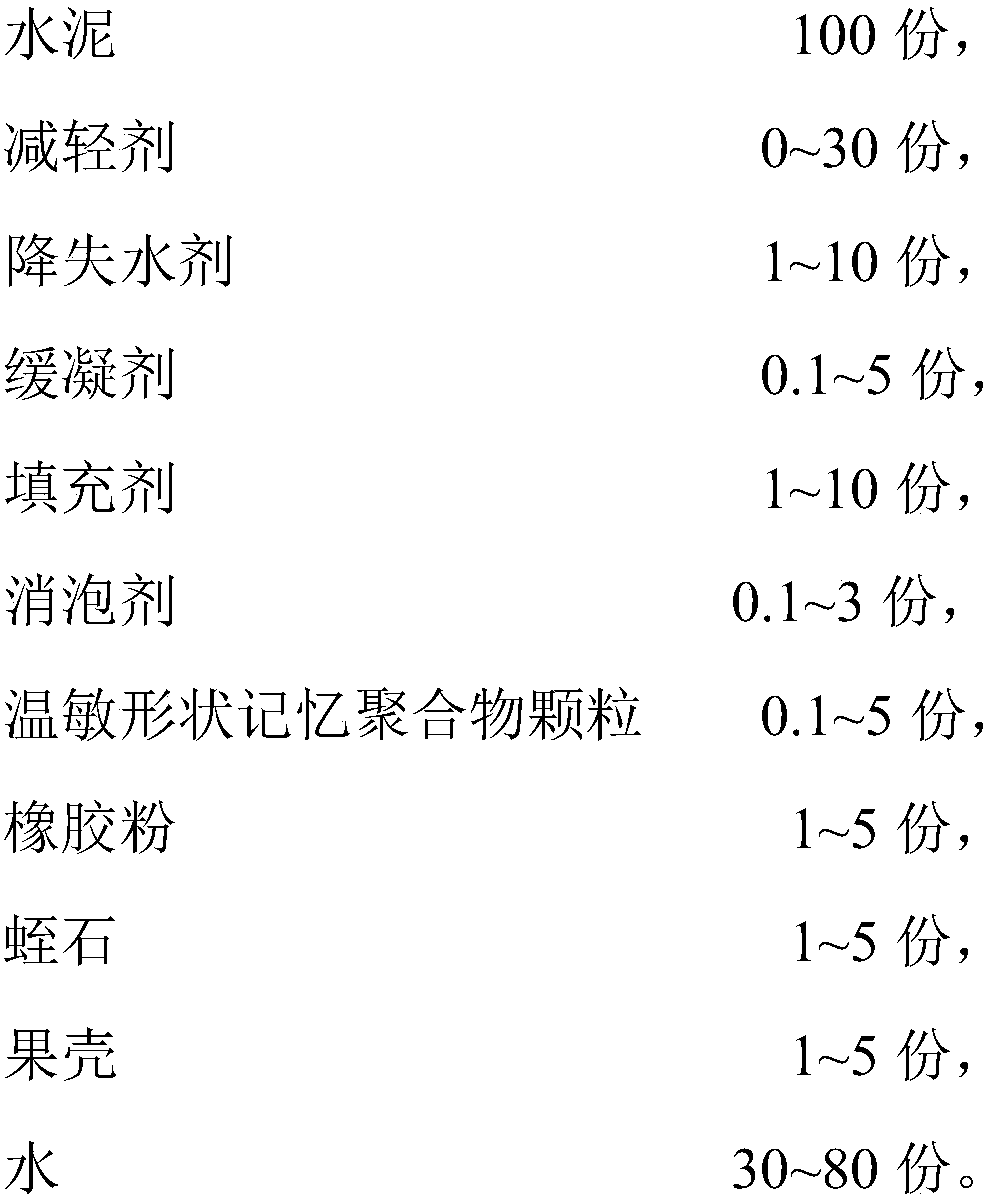

Method used

Image

Examples

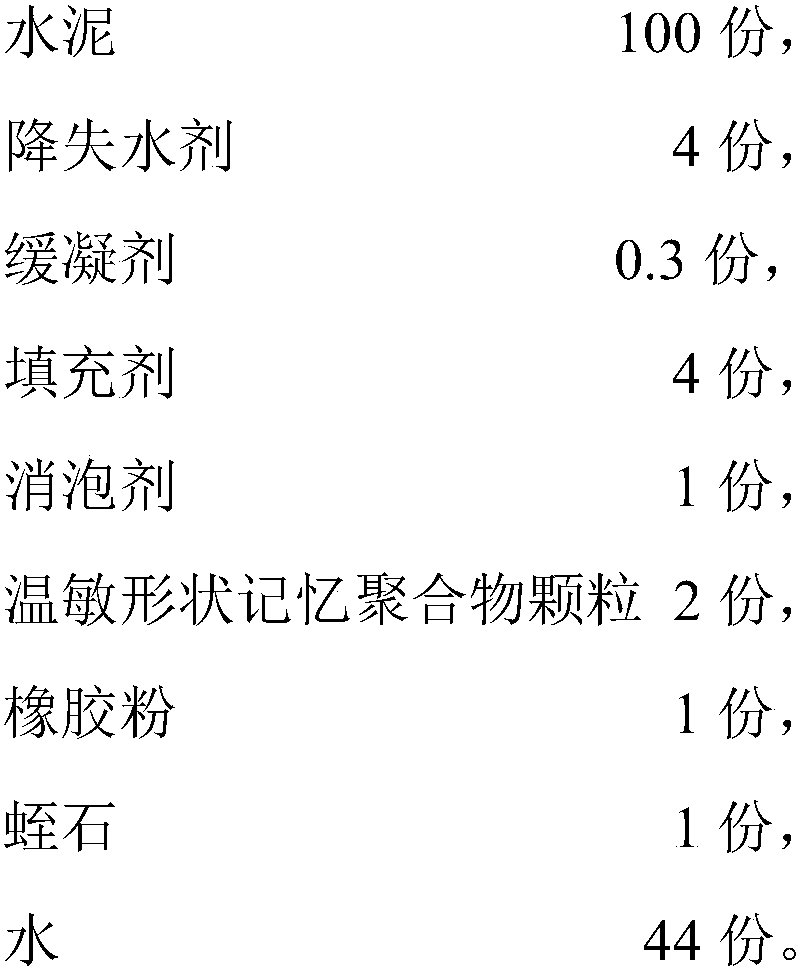

Embodiment 1

[0035]

[0036] The fluid loss reducer used is DZJ-Y (AMPS multi-polymer copolymer) produced by Sinopec Engineering Institute, the retarder is DZH-2 (organic phosphoric acid) produced by Sinopec Engineering Institute, and the filler is micro silicon (400 mesh). The foaming agent is DZX (silicon oil) produced by Sinopec Engineering Institute; the particle size of rubber powder is 500um~3mm, and the particle size of vermiculite is 0.5mm~4mm.

[0037] The preparation method of temperature-sensitive shape-memory polymer particles is as follows: styrene-butadiene temperature-sensitive shape-memory polymer (the shape-memory deformation temperature is 50-110°C, purchased from Dezhou Continental Shelf Petroleum Engineering Technology Co., Ltd.) After freezing and crushing, the temperature after liquid nitrogen cryogenic freezing is -10°C to -20°C, and the temperature-sensitive shape memory polymer after crushing is 20 mesh to 80 mesh. The fibers are polypropylene fiber (polypropyle...

Embodiment 2

[0041]

[0042] The lightening agent used is fly ash, the water loss reducing agent is FSAM (PVA polymer) produced by Sinopec Engineering Institute, the retarder is DZH-2 produced by Sinopec Engineering Institute, the filler is micro silicon (400 mesh), defoaming The agent is DZX produced by Sinopec Engineering Institute, the particle size range of fruit shell is 0.5-5mm, the particle size of rubber powder is 500um-3mm, and the particle size of vermiculite is 0.5mm-4mm.

[0043] The preparation method of temperature-sensitive shape-memory polymer particles is as follows: styrene-butadiene temperature-sensitive shape-memory polymer (the shape-memory deformation temperature is 50-110°C, purchased from Dezhou Continental Shelf Petroleum Engineering Technology Co., Ltd.) After freezing and crushing, the temperature after liquid nitrogen cryogenic freezing is -10°C to -20°C, and the temperature-sensitive shape memory polymer after crushing is 20 mesh to 80 mesh. The fibers are p...

Embodiment 3

[0047]

[0048] The lightening agent used is fly ash, the water loss reducer is FSAM (polyvinyl alcohol polymer) produced by Sinopec Engineering Institute, the retarder is DZH-2 produced by Sinopec Engineering Institute, and the filler is micro silicon (400 mesh). The foaming agent is DZX, and the rubber powder particle size is 500um~3mm. Vermiculite particle size is 0.5mm ~ 4mm.

[0049] The preparation method of temperature-sensitive shape-memory polymer particles is as follows: the temperature-sensitive shape-memory polymer of styrene-butyl acrylate copolymer (the shape-memory deformation temperature is 50-110°C, purchased from Dezhou Continental Shelf Petroleum Engineering Technology Co., Ltd.) Nitrogen cryogenically freezes and pulverizes, liquid nitrogen freezes at a temperature of -10°C to -20°C, and the pulverized temperature-sensitive shape memory polymer is 20 mesh to 80 mesh. The fibers are polypropylene fiber (polypropylene fiber) and polyvinyl chloride fiber (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com