Self-compacting concrete and preparation method thereof

A technology of self-compacting concrete and mixture, applied in the field of concrete, can solve the problems of low pumpability, low compactness and compression resistance, poor fluidity of self-compacting concrete, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

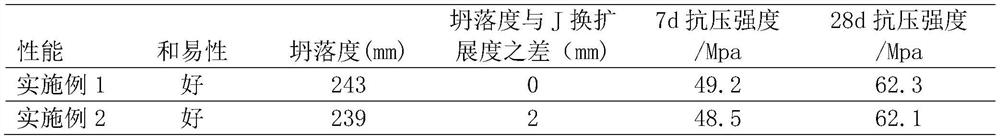

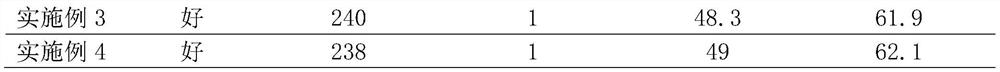

Examples

Embodiment 1

[0031] Prepare the following raw material components: 136 parts of cement, 107 parts of modified mineral powder, 77 parts of coal ash, 927 parts of gravel, 204 parts of coarse sand, 469 parts of fine sand, 122 parts of water and 11.4 parts of admixture. Among them, the admixture is composed of the following raw materials in parts by weight: 4.6 parts of polycarboxylate water reducer, 2.3 parts of binder, 1.7 parts of expansion agent, 2.4 parts of nano-graphite and 1.4 parts of polystyrene nano-microspheres.

[0032] Prepare self-compacting concrete as follows:

[0033] Step 1, mixing coal ash and 1 / 2 modified slag powder evenly, then adding coarse sand and crushed stone to form an aggregate mixture;

[0034] Step 2, mixing and stirring the cement and the remaining 1 / 2 modified slag powder to obtain a slurry mixture;

[0035] Step 3, adding the slurry mixture prepared in step 2 to the aggregate mixture in step 1 and stirring evenly to obtain a mixing material;

[0036] Step 4...

Embodiment 2

[0038] Prepare the following raw materials in parts by weight: 128 parts of cement, 114 parts of modified mineral powder, 81 parts of coal ash, 886 parts of gravel, 214 parts of coarse sand, 504 parts of fine sand, 116 parts of water and 8.9 parts of admixture. The raw materials of the admixture are preferably composed of 4.6 parts of polycarboxylate water reducer, 2.3 parts of binder, 1.7 parts of expansion agent, 2.4 parts of nano-graphite and 1.4 parts of polystyrene nano-microspheres.

[0039] Self-compacting concrete was prepared according to the method of Example 1.

Embodiment 3

[0041] Prepare the following raw materials in parts by weight: 112 parts of cement, 125 parts of modified mineral powder, 85 parts of coal ash, 800 parts of gravel, 233 parts of coarse sand, 455 parts of fine sand, 110 parts of water and 8 parts of admixture.

[0042] Self-compacting concrete was prepared according to the method of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com