Pumping concrete admixture capable of improving pumpability and preparation method thereof

A technology for pumping concrete and pumping performance, which is applied in the field of pumping concrete admixtures and its preparation, can solve problems such as difficulty in application, expensive silica fume, and lack of high-quality fly ash, and achieve low product cost and improved workability , the effect of improving pumpability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

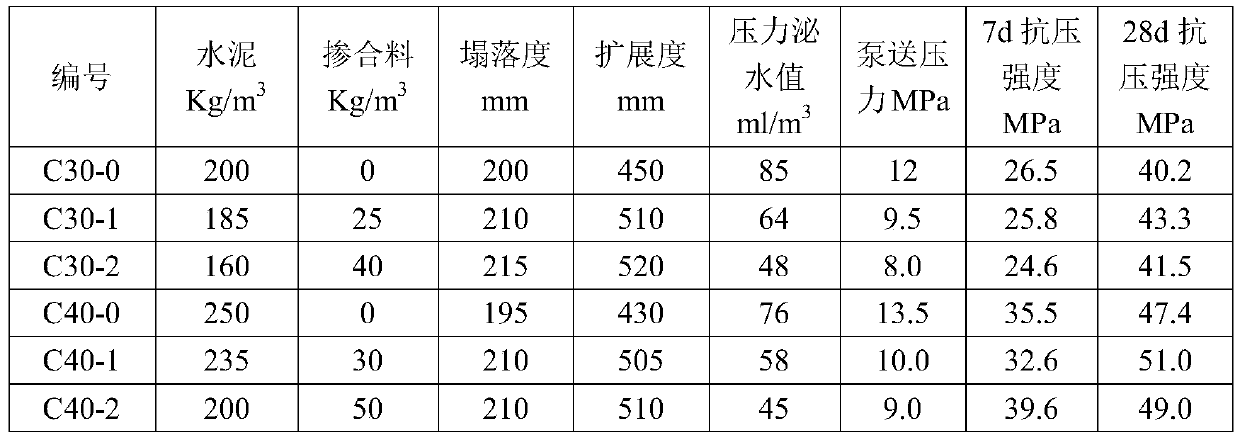

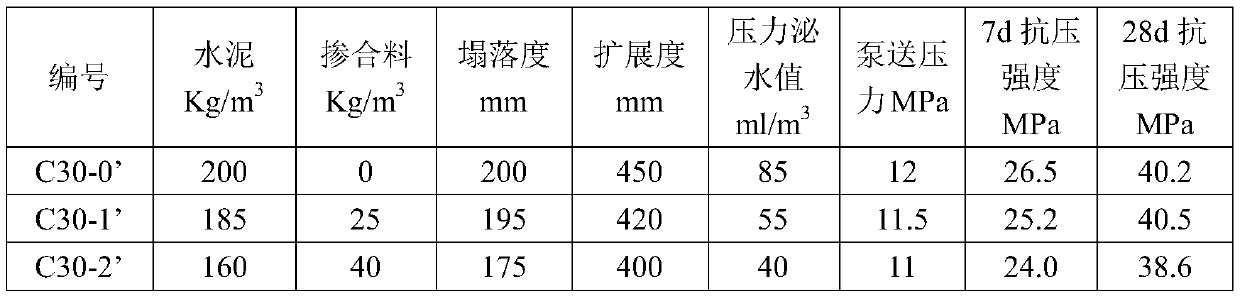

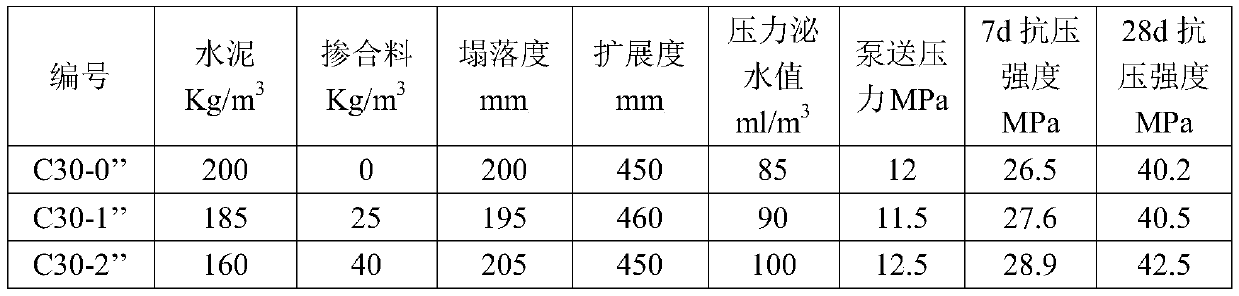

Examples

Embodiment 1

[0031] Preparation of pumpable concrete admixtures for improved pumpability

[0032] The raw material composition of this embodiment is: by weight, copper tailing slag 75, granulated blast furnace slag 25, admixture 0.1, admixture is plasticized by the mass ratio of 1:1:2 triethanolamine, polyvinyl alcohol and polycarboxylic acid agent composition. The specific preparation method is as follows:

[0033] (1) separating the muddy copper tailings through a hydrocyclone to separate particles with a particle size of less than 200 meshes, then settling and concentrating, and then dehydrating through a filter press to obtain a copper tailing mud cake with a moisture content of 10%;

[0034] (2) Mix the cake-like material of copper tailing slag with granulated blast furnace slag, then dry and grind in a vertical mill or drying mill until the specific surface area is greater than 550m 2 / kg, and during the grinding process, the admixture is sprayed to obtain the pumpable concrete adm...

Embodiment 2

[0036] Preparation of pumpable concrete admixtures for improved pumpability

[0037] The raw material composition of this embodiment is: by weight, copper tailings 70, granulated blast furnace slag 30, admixture 0.05, admixture is plasticized by the mass ratio of 1:1:2 triethanolamine, polyvinyl alcohol and polycarboxylic acid agent composition. The specific preparation method is as follows:

[0038] (1) separating the muddy copper tailings through a hydrocyclone to separate particles with a particle size less than 200 meshes, then settling and concentrating, and then dehydrating through a filter press to obtain a copper tailing mud cake with a moisture content of 9%;

[0039] (2) Mix the cake-like material of copper tailing slag with granulated blast furnace slag, then dry and grind in a vertical mill or drying mill until the specific surface area is greater than 550m 2 / kg, and during the grinding process, the admixture is sprayed to obtain the pumpable concrete admixture th...

Embodiment 3

[0041] Preparation of pumpable concrete admixtures for improved pumpability

[0042] The raw material composition of this embodiment is: by weight, copper tailings 80, granulated blast furnace slag 20, admixture 0.1, admixture is plasticized by the mass ratio of 1:1:2 triethanolamine, polyvinyl alcohol and polycarboxylic acid agent composition. The specific preparation method is as follows:

[0043] (1) separating the muddy copper tailings through a hydrocyclone to separate particles with a particle size of less than 200 meshes, then settling and concentrating, and then dehydrating through a filter press to obtain a copper tailing mud cake with a moisture content of 8%;

[0044] (2) Mix the cake-like material of copper tailing slag with granulated blast furnace slag, then dry and grind in a vertical mill or drying mill until the specific surface area is greater than 550m 2 / kg, and during the grinding process, the admixture is sprayed to obtain the pumpable concrete admixtur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com