A kind of ceramsite buoyancy suppression agent and method for reducing ceramsite floating degree in pumped ceramsite concrete

A technology of ceramsite concrete and ceramsite, which is applied in the direction of instruments and analysis materials, etc., can solve problems such as failure to propose, detection and acceptance errors, and poor guidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Embodiment 1: The method for measuring the floating index of ceramsite of the present invention, and the effect comparison with the conventional method for measuring the degree of stratification

[0053] 1. LC7.5 pumping ceramsite concrete mix ratio, shale ceramsite density grade is 700kg / m 3 , see Table 1.

[0054] Table 1 LC7.5 pumping ceramsite concrete mix ratio

[0055]

[0056] 2. Method for measuring floating index of ceramsite of the present invention

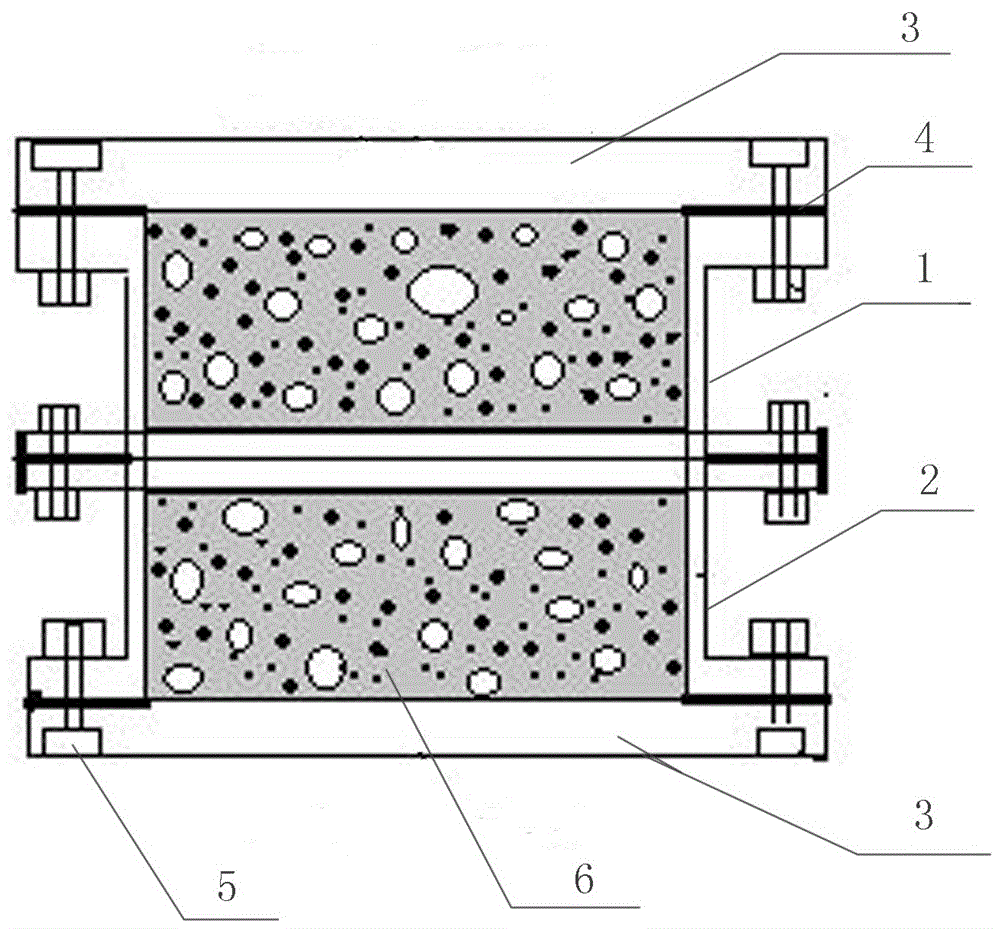

[0057] 1) The instrument for measuring the ceramsite floating index of the ceramsite concrete sample adopts the ceramsite floating index detection cylinder, and the ceramsite floating index detection cylinder described above (see figure 1 ): Including the upper and lower layers of interconnected square metal cylinders, that is, the upper metal cylinder 1 and the lower metal cylinder 2, the upper and lower ends of the detection cylinder are respectively equipped with metal cover plates 3, and the square side ...

Embodiment 2

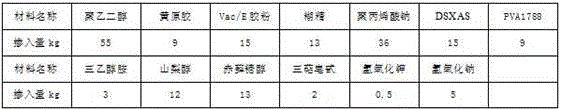

[0073] Example 2: The formula 1 of ceramsite anti-floating and drag-reducing agent and its effect verification for reducing the floating degree of ceramsite in pumped ceramsite concrete

[0074] 1. The mix proportion of LC10 pumped ceramsite concrete, the prepared slump is 200mm, see Table 3.

[0075] Table 3 LC10 pumping ceramsite concrete mix ratio

[0076]

[0077] 2. Detection and evaluation of floating index of ceramsite

[0078] The ceramsite floating index detection method is the same as embodiment 1 detection method of the present invention, and the detection result of the ceramsite floating index of the ceramsite concrete whose proportioning is Table 3 is 15.1%;

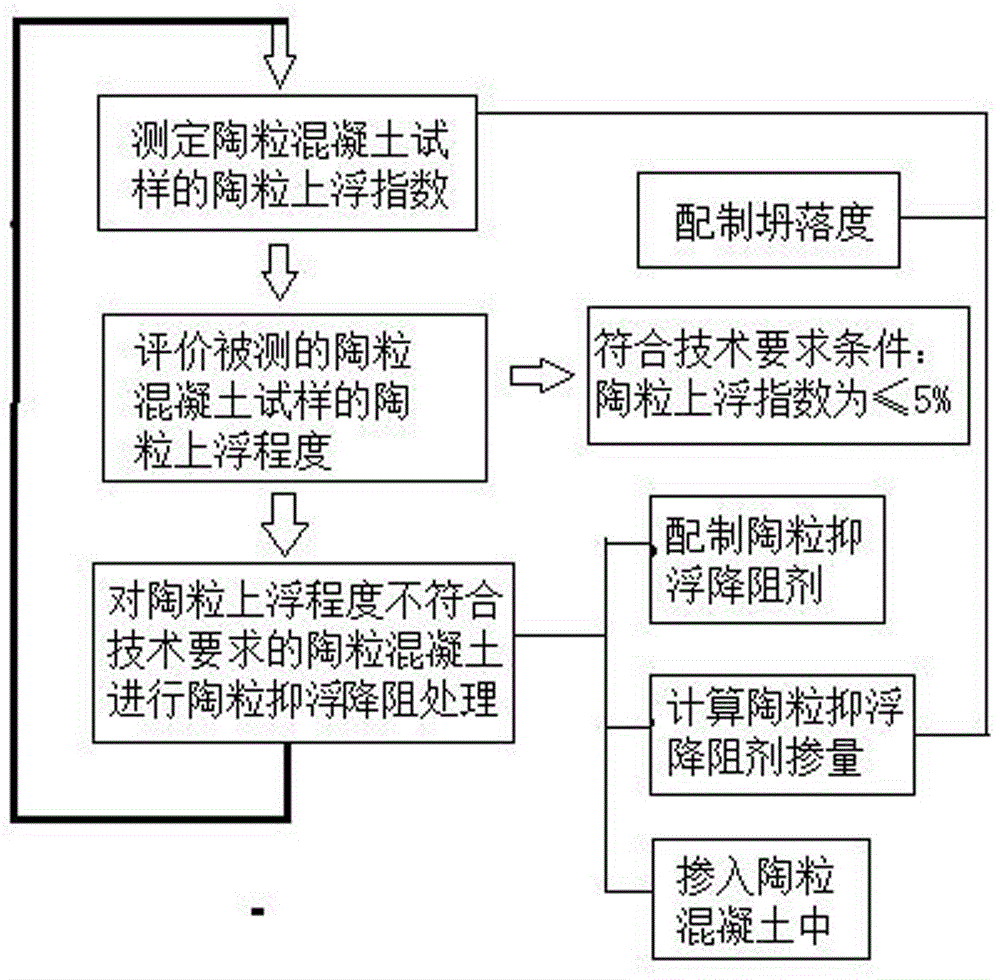

[0079] Evaluate the ceramsite floating degree of the ceramsite concrete in Table 3: According to the measured ceramsite floating index, judge whether the ceramsite concrete meets the pumping construction requirements. The judgment standard is: when the ceramsite floating index is ≤5%, the ceramsite The ...

Embodiment 3

[0104] Example 3: Formula 2 of ceramsite anti-floating and drag-reducing agent and its effect verification for reducing the floating degree of ceramsite in pumped ceramsite concrete

[0105] 1. The mix ratio of LC15 pumped ceramsite concrete, the prepared slump is 220mm, see Table 5.

[0106] Table 5 LC15 pumping ceramsite concrete mix ratio

[0107]

[0108] 2. Detection and evaluation of floating index of ceramsite

[0109] Ceramsite floating index detection method is the same as embodiment 1 detection method of the present invention, and the detection result of the ceramsite floating index of the ceramsite concrete whose proportioning is Table 5 is 16.8%;

[0110] Evaluate the ceramsite floating degree of the ceramsite concrete in Table 3: According to the measured ceramsite floating index, judge whether the ceramsite concrete meets the pumping construction requirements. The judgment standard is: when the ceramsite floating index is ≤5%, the ceramsite The concrete meet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com