Plasticity stabilizer for mechanical spraying mortar

A technology of mechanical spraying and plastic stabilizer, applied in the field of building materials, can solve the problems of mechanized construction progress and efficiency not meeting the requirements, pumping performance not meeting the requirements, and mortar storage period short, etc., to improve workability and Constructability, work performance satisfaction, and the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

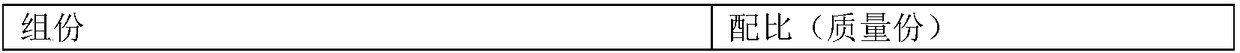

[0029] A plastic stabilizer for mechanical spraying mortar, the proportioning ratio of its components is as shown in Table 1:

[0030] Component

[0031] Preparation method: Weigh each component according to the mass ratio in Table 1, add it into a gravity-free mixer, and mix well to obtain a plastic stabilizer for mechanical spraying mortar.

Embodiment 2

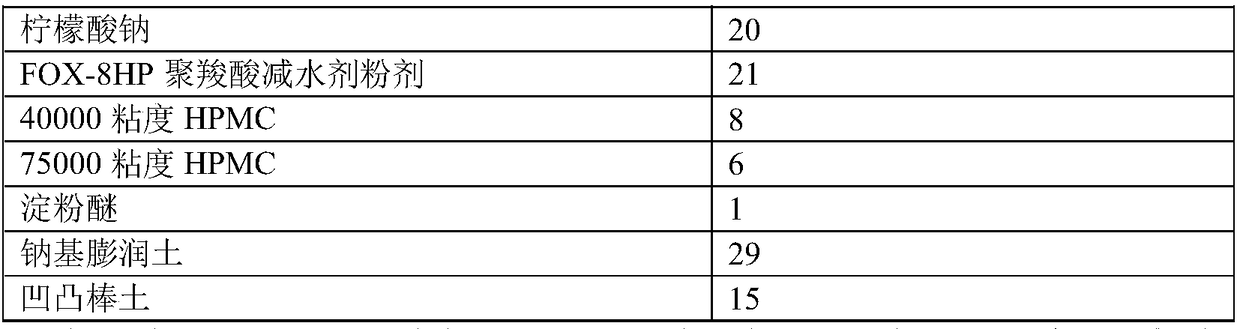

[0033] A plastic stabilizer for mechanical spraying mortar, the proportioning ratio of its components is as shown in Table 2:

[0034] Component

[0035] Preparation method: Weigh each component according to the mass ratio in Table 2, add it into a gravity-free mixer, and mix well to obtain a plastic stabilizer for mechanical spraying mortar.

Embodiment 3

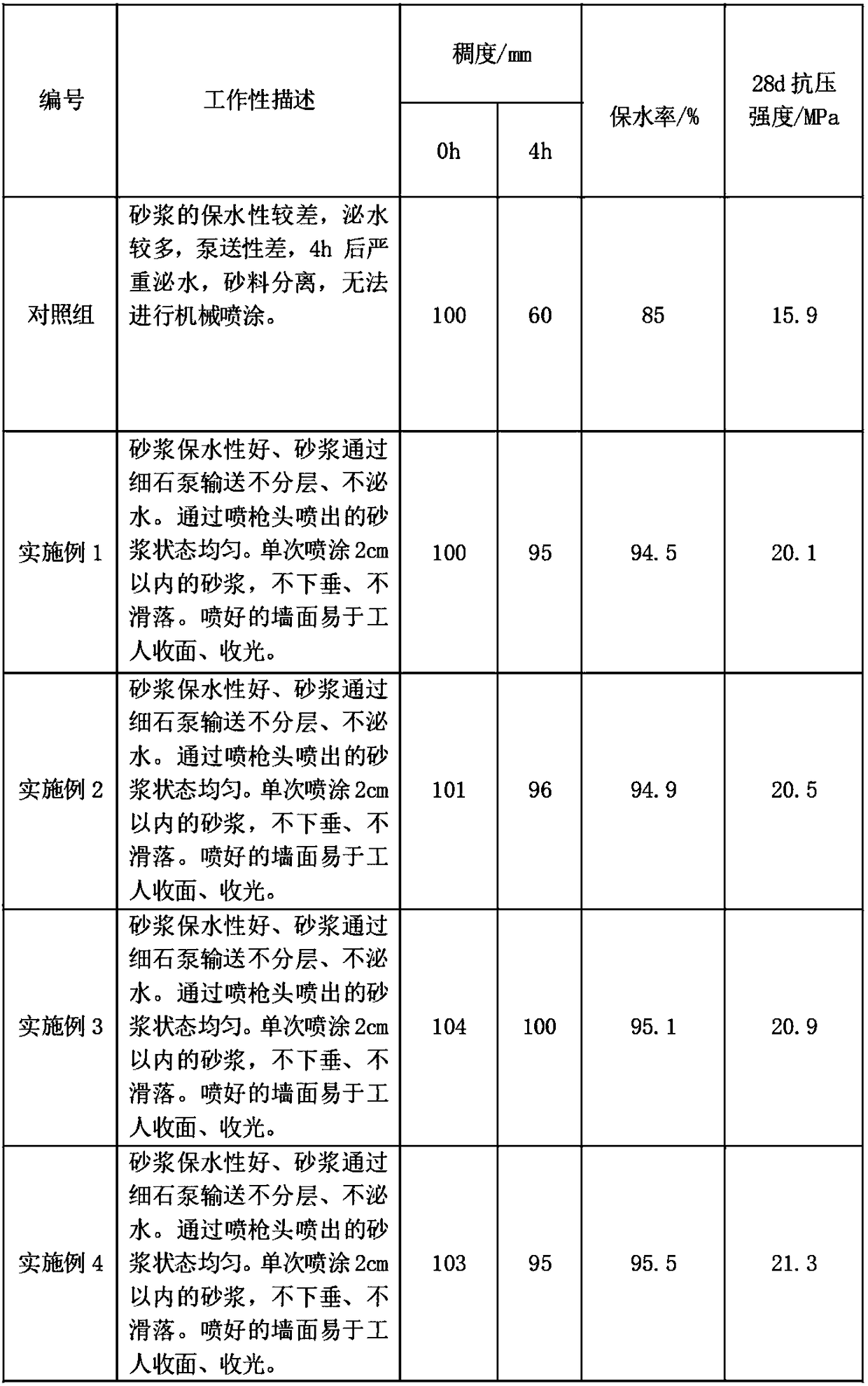

[0037] A plastic stabilizer for mechanical spraying mortar, the proportioning ratio of its components is as shown in table 3:

[0038] Component

[0039] Preparation method: Weigh each component according to the mass ratio in Table 3, add it into a gravity-free mixer, and mix well to obtain a plastic stabilizer for mechanical spraying mortar.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com