Bleeding-reduced-type concrete admixture by using marble powder as major and preparation method thereof

A marble and concrete technology, applied in the field of building materials, can solve the problem of inability to completely dispose of stone powder waste, and achieve the effects of good concrete homogeneity, improved cohesion, and improved pumping performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

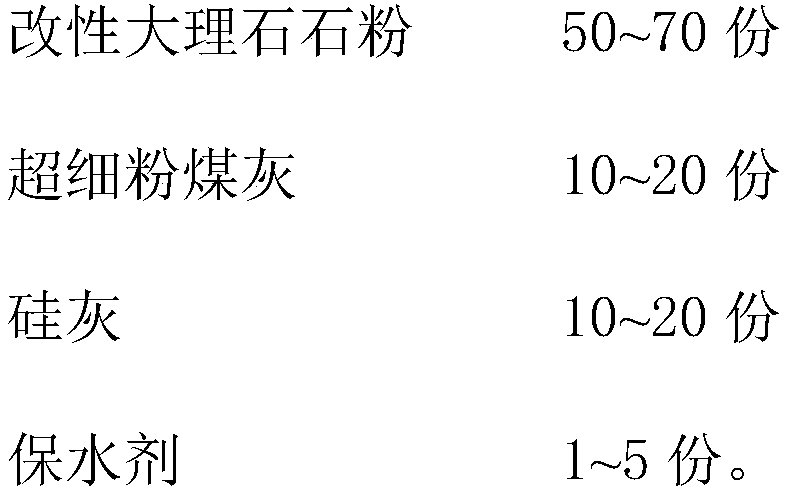

Method used

Image

Examples

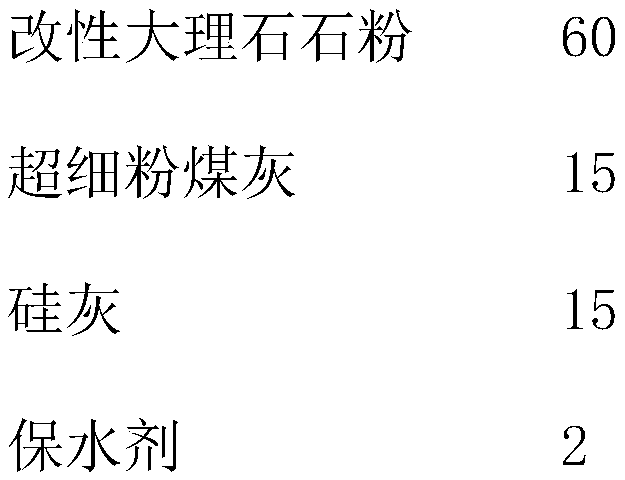

Embodiment 1

[0025] (1) Preparation of grinding aid: 50.00g of triethanolamine, 50.00g of triethylenepropanolamine, 60.00g of molasses, urea solution (16.00g of urea, 84.00g of water), glycerin (2.00g of glycerin, 98.00g of water), drip Add it into 640.00g of water for reaction, raise the temperature to 50°C for reaction, and add it dropwise for 1 hour to obtain a grinding aid.

[0026] (2) Preparation of modified marble powder: Add 5000.00 g of waste marble powder and 1.00 g of grinding aid into a ball mill, grind for 20 minutes, and keep 60°C during the process to prepare modified marble powder.

[0027] (3) Preparation of powder polycarboxylate superplasticizer: Add 2.00 g of stabilizer anhydrous sodium acetate to 1000.00 g of polycarboxylate water reducer mother liquor, control the temperature at 100° C., and centrifugally dry to obtain powder polycarboxylate superplasticizer.

[0028] (4) Preparation of water-retaining agent: Mix 100.00 g of powder polycarboxylate superplasticizer, 20...

Embodiment 2

[0033] (1) Grinding aid preparation: N, N dimethylethanolamine 60.00g, diethanol monoisopropanolamine 40.00g, molasses 70.00g, urea solution (urea 20.00g, water 80.00g), glycerin (glycerin 2.50g , water 97.50g), added dropwise into 630.00g water to react, heated up to 45°C for reaction, and the dropwise addition time was 0.75h to obtain a grinding aid.

[0034] (2) Preparation of modified marble powder: Put 5000.00 g of waste marble powder and 1.20 g of grinding aid into a ball mill, grind for 25 minutes, and keep 60°C during the process to prepare modified marble powder.

[0035] (3) Preparation of powder polycarboxylate superplasticizer: Add 1.50 g of stabilizer active anhydrous copper sulfate and 1.00 g of sodium sulfate to 1000.00 g of polycarboxylate water reducer mother liquor, control the temperature at 100 ° C, and centrifugally dry to obtain powder poly Carboxylic acid superplasticizer.

[0036] (4) Preparation of water-retaining agent: Mix 100.00 g of powder polycar...

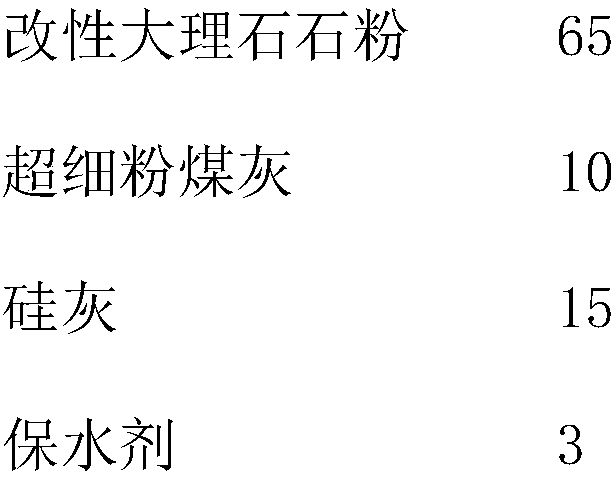

Embodiment 3

[0041](1) Grinding aid preparation: 60.00g of N,N-dibenzylethanolamine, 20.00g of diethanolamine, 20.00g of diethanol monoisopropanolamine, 70.00g of molasses, urea solution (20.00g of urea, 80.00g of water) 1. Glycerin (3.50 g of glycerol, 96.50 g of water), was added dropwise into 630.00 g of water for reaction, and the temperature was raised to 45° C. for reaction, and the dropwise addition time was 1.5 h to obtain a grinding aid.

[0042] (2) Preparation of modified marble powder: Put 5000.00 g of waste marble powder and 1.50 g of grinding aid into a ball mill, grind for 25 minutes, and keep 60°C during the process to prepare modified marble powder.

[0043] (3) Preparation of powder polycarboxylate superplasticizer: Add 1.50 g of stabilizer potassium carbonate and 1.00 g of anhydrous sodium acetate to 1000.00 g of polycarboxylate water reducer mother liquor, control the temperature at 100 ° C, and centrifugally dry to obtain powder polycarboxylate Acid superplasticizer. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com