Method for selecting arm support accroding to the pumping distance in concrete pump vehicle

A concrete pump truck and concrete pump technology, which is applied in the processing of building materials, construction, building structure, etc., can solve problems such as affecting construction efficiency, accelerating pipeline wear, and pumping concrete with small elevation or span distance, etc. The effect of improving work stability, improving construction efficiency and reducing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

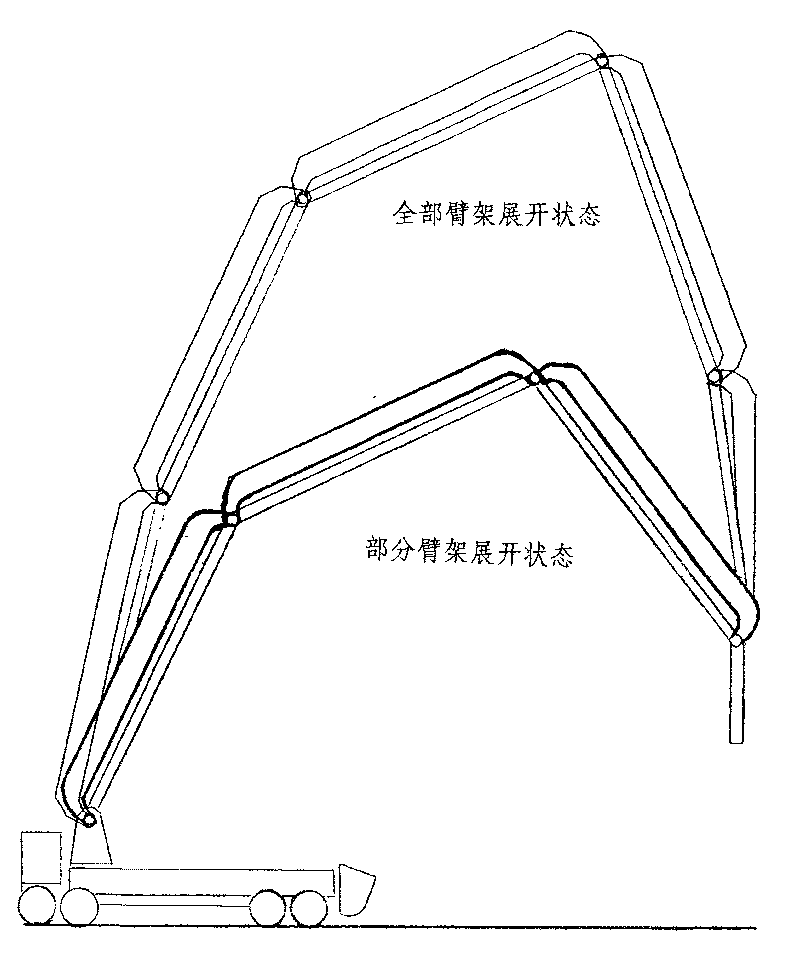

[0021] figure 1 It is a schematic diagram of the working state of pumping concrete before and after the implementation of the present invention

[0022] The figure shows that when the pumping distance of concrete is the same and the construction conditions are the same, when using the existing technology to deploy all the booms and using the present invention to deploy only part of the booms for concrete pumping construction, the two types of concrete pump trucks different working status.

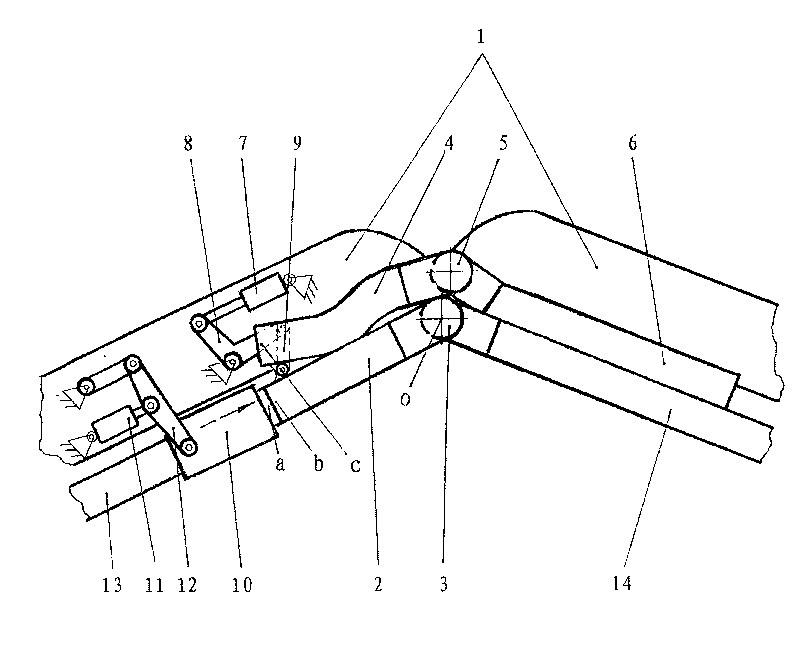

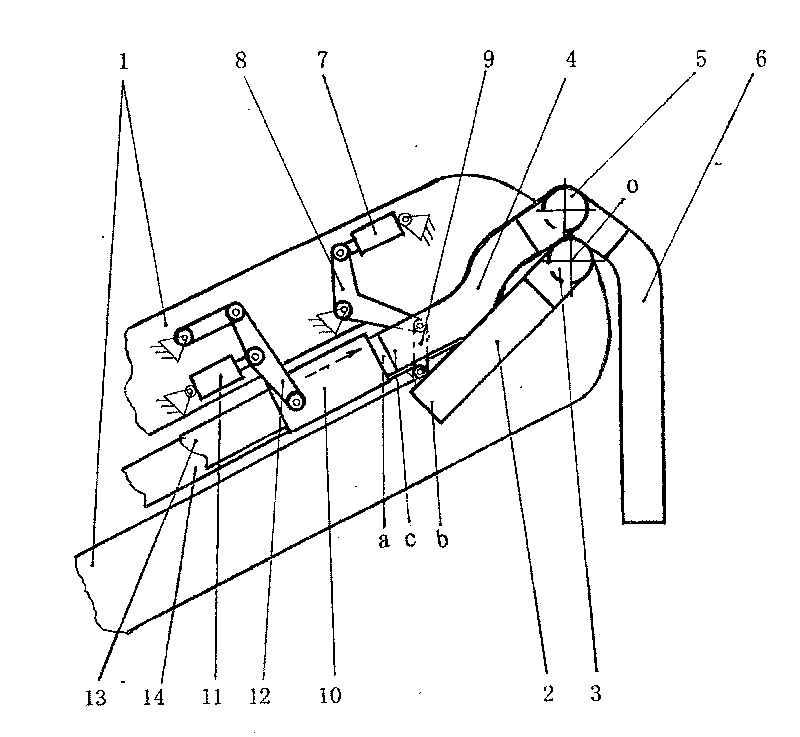

[0023] figure 2 It is a schematic diagram of the working principle of the auxiliary concrete discharge mechanism in the state of long-distance pumping of concrete when the boom is deployed.

[0024] When the concrete pump truck is carrying out long-distance pumping concrete construction operations, the pipeline switching cylinder 7 pushes the rocker arm 8, so that the connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com