An electro-hydraulic throttle salvage tool and its salvage method

A salvage tool and choke technology, applied in the field of electro-hydraulic choke salvage tools, can solve the problems of high cost of choke, low success rate of salvage measures, etc., to reduce pump pressure, improve salvage success rate, Effectiveness of reliable and low-cost salvage techniques and economic requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

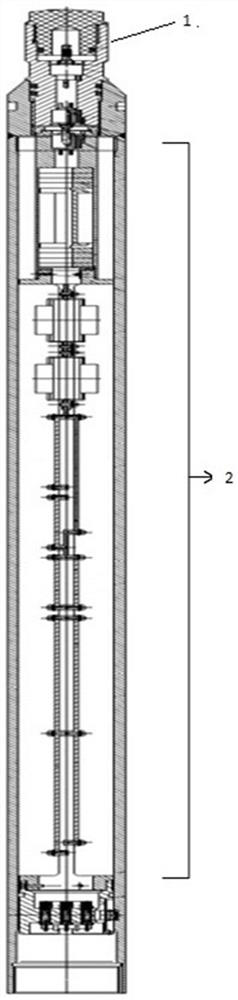

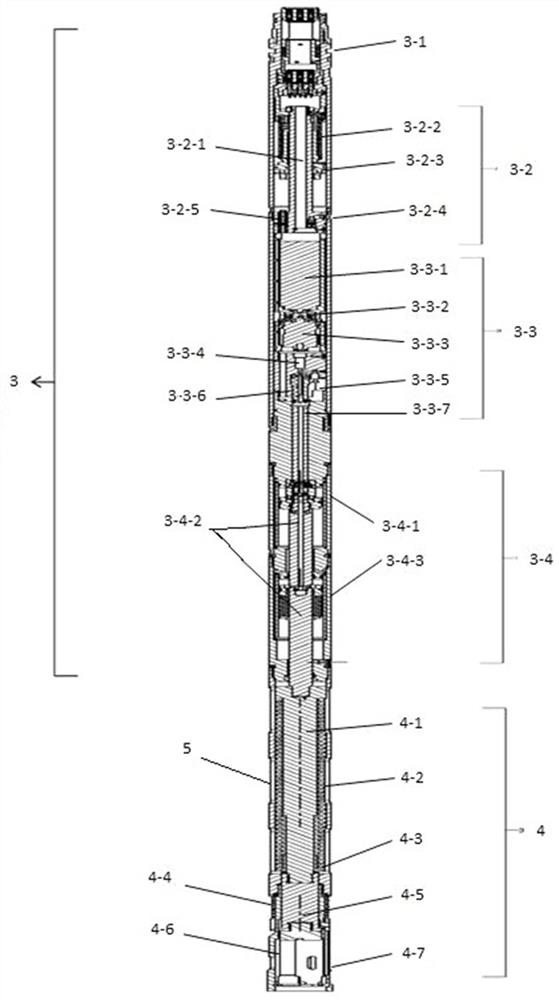

[0048] The first embodiment of the present invention relates to an electro-hydraulic choke fishing tool, such as figure 1 and figure 2As shown, it includes a casing 5, the top of the casing 5 is an upper joint 1 for the cable to pass through, and the casing 5 is encapsulated in order from top to bottom with an electronic short joint 2, a hydraulically driven short joint 3 and a self-resetting salvage spear short joint 4, The electronic sub-section 2 is electrically connected with the hydraulic driving sub-section 3, and the hydraulic-driving sub-section 3 pushes the self-resetting salvage spear sub-section 4 to grab the throttle through hydraulic oil.

[0049] The working process of the electro-hydraulic throttle salvage tool is as follows:

[0050] Inject hydraulic oil into the electro-hydraulic choke salvage tool, and the hydraulic oil fills the hydraulic drive sub-section 3; use the cable to pass through the upper joint 1 and electrically connect with the electronic sub-s...

no. 2 approach

[0054] This embodiment relates to an electro-hydraulic throttle salvage tool, such as figure 1 and figure 2 As shown, it includes a casing 5, the top of the casing 5 is an upper joint 1 for the cable to pass through, and the casing 5 is encapsulated in order from top to bottom with an electronic short joint 2, a hydraulically driven short joint 3 and a self-resetting salvage spear short joint 4, The electronic sub-section 2 is electrically connected with the hydraulic driving sub-section 3, and the hydraulic-driving sub-section 3 pushes the self-resetting salvage spear sub-section 4 to grab the throttle through hydraulic oil.

[0055] The hydraulic drive short joint 3 includes, from top to bottom, a connecting joint 3-1, a hydraulic balance mechanism 3-2, a hydraulic power mechanism 3-3 and a driving hydraulic cylinder mechanism 3-4. The lower end of the electronic short joint 2 is connected to the connecting joint 3-2. 1. Sealed and plugged, the hydraulic balance mechanism ...

no. 3 approach

[0063] This embodiment relates to an electro-hydraulic throttle salvage tool, such as figure 1 and figure 2 As shown, it includes a casing 5, the top of the casing 5 is an upper joint 1 for the cable to pass through, and the casing 5 is encapsulated in order from top to bottom with an electronic short joint 2, a hydraulically driven short joint 3 and a self-resetting salvage spear short joint 4, The electronic sub-section 2 is electrically connected with the hydraulic driving sub-section 3, and the hydraulic-driving sub-section 3 pushes the self-resetting salvage spear sub-section 4 to grab the throttle through hydraulic oil.

[0064] The hydraulic drive short joint 3 includes, from top to bottom, a connecting joint 3-1, a hydraulic balance mechanism 3-2, a hydraulic power mechanism 3-3 and a driving hydraulic cylinder mechanism 3-4. The lower end of the electronic short joint 2 is connected to the connecting joint 3-2. 1. Sealed and plugged, the hydraulic balance mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com