A kind of universal drilling tool overhauler and its overhauling method

An overshot, general-purpose technology, applied in the fields of drilling and drilling machinery, can solve the problems of low success rate of drilling tools salvage, damage to drilling tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

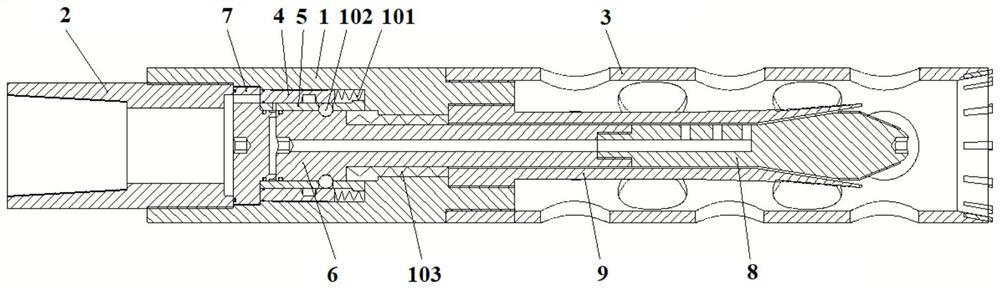

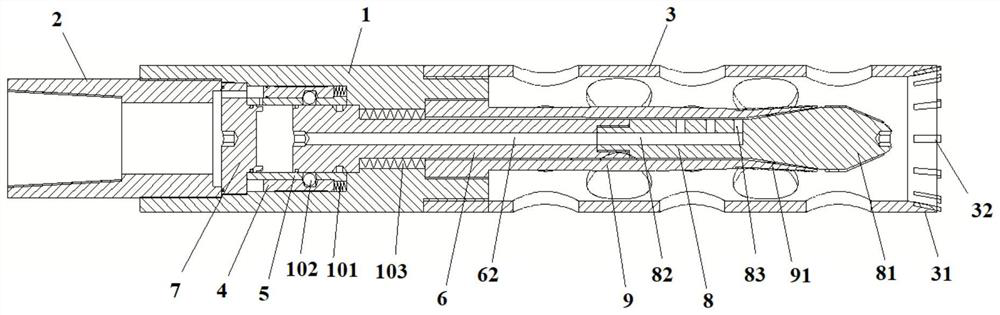

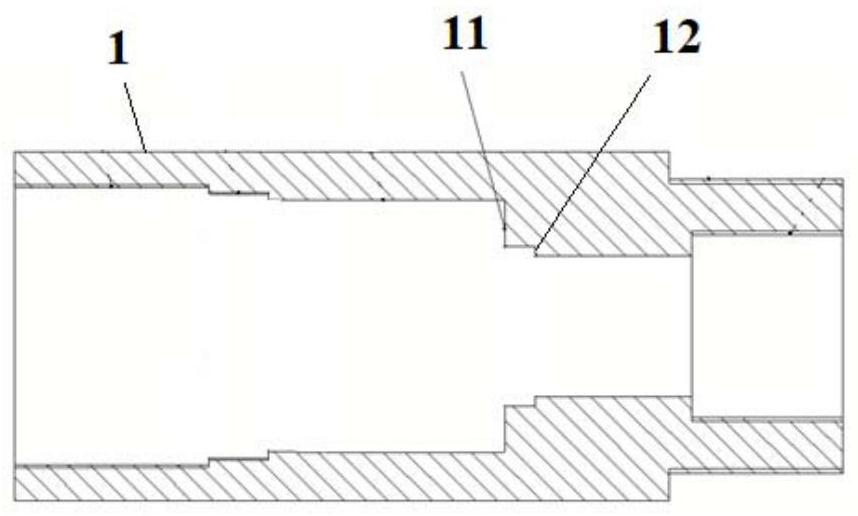

[0045] Such as Figure 1 to Figure 7 As shown, this embodiment provides a general-purpose drilling tool overshot, which includes an outer tube 1, and the two ends of the outer tube 1 are respectively provided with a reducing pipe 2 and a sleeve that are coaxial with the outer tube 1 and detachable and fixedly communicated. 3. In the outer tube 1, there are coaxial sleeves from outside to inside: an annular pilot piston 4 capable of axial movement, an inner tube 5 with a water hole 51 on the side wall, and a hollow piston rod 6 capable of axial movement; An end cover 7 is provided at the end of the hollow piston rod 6 and the ring-shaped pilot piston 4, one end of the end cover 7 is close to the end of the reducing pipe 2, and the other end is fixedly connected with the end of the inner tube 5, and the end cover 7 is provided with There is an axial water inlet channel 71; the hollow piston rod 6 extends into the sleeve 3, and the coaxial core rod 8 is connected to the tail of t...

Embodiment 2

[0056] This embodiment provides a kind of salvage method of the general-purpose drilling tool overshot in embodiment 1, and this salvage method comprises the following steps:

[0057] Step 1: Connect the external salvage drill pipe to the variable diameter joint, send the general-purpose drilling tool overshot to the place where the drill tool breaks or falls, and pass high-pressure water into the external salvage drill pipe to the variable diameter joint. Under the action, the annular pilot piston moves to the right, and the first spring compresses the annular pilot piston to move axially until the tapered through hole is aligned with the first annular groove, forming an unlocking groove; the high-pressure water further passes through the water hole, and the high-pressure water Under the action, the hollow piston rod tends to move to the right, and the hemisphere of the limiting bead is squeezed into the unlocking groove. The hollow piston rod and the core rod move to the righ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com