Viscosity reduction type liquid phase composition, preparation method and application thereof

A composition and liquid-phase technology, applied in the field of viscosity-reducing liquid-phase composition and its preparation, viscosity-reducing superplasticizer and its preparation, can solve problems such as difficult construction, high-strength concrete, and heavy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

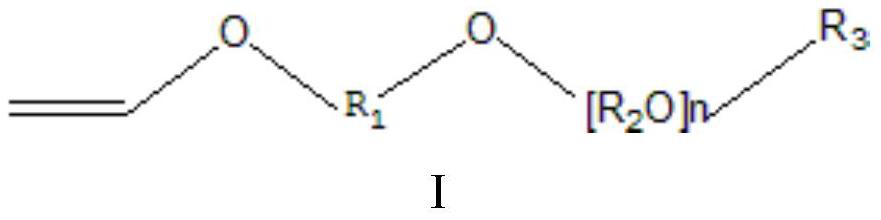

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0066] Preparation Example 1 Preparation of water-reducing mother liquor TL-01

[0067] 49g of polyether macromonomer (molecular weight: 3000, commercially available product WR6251 of Levima Advanced Materials Technology Co., Ltd.) prepared with 2-methallyl alcohol as an initiator was placed in a kettle and dissolved in 32.5g of water, Add 0.06g of hydrogen peroxide (30% by mass aqueous solution), then start to drop 5.2g of acrylic acid, 0.08g of L-ascorbic acid, 0.22g of thioglycolic acid and water mixture, the time of adding is 2.5h, after the addition is completed, ripen for 1h, Cool to room temperature to obtain water-reduced mother liquor TL-01.

[0068] Preparation example 2 Preparation of slump-preserving mother liquor TLB-01

[0069] Put 49g of polyether macromonomer (molecular weight: 2400, commercially available product SR7302 of Levima Advanced Materials Technology Co., Ltd.) prepared with isopentenol as an initiator and dissolve it in 32.5g of water, add 0.06g Hy...

Embodiment 1

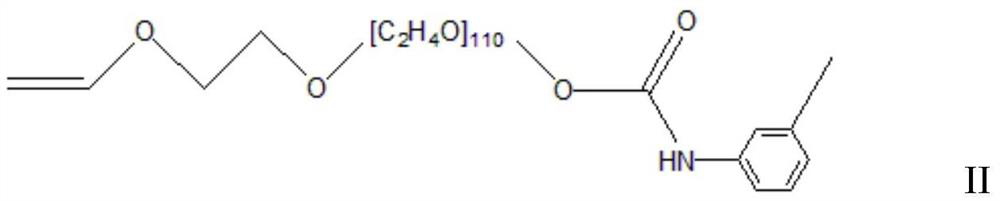

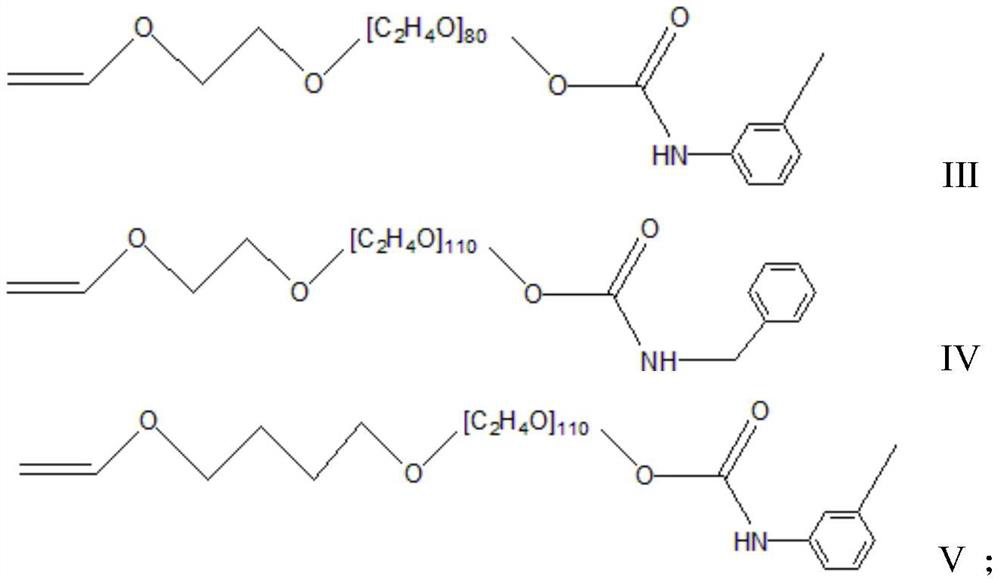

[0071] 49g is prepared with reference to the embodiment of CN109679086A, and the polyether macromonomer (weight average molecular weight is about 5000) prepared by using 2-vinyloxyethanol as an initiator and end-blocking with m-toluene isocyanate is placed in a kettle in 32.5g of water Dissolve, add 0.06g hydrogen peroxide (30% by mass aqueous solution), then start to dropwise add 4.9g acrylic acid, 0.12gL-ascorbic acid, 0.38g mercaptoacetic acid mixed solution, dropwise time is 50min, after dropwise addition, ripen for 1.5h, Cool to room temperature to obtain viscosity-reducing mother liquor A, and compound it with water-reducing mother liquor TL-01 and slump-preserving mother liquor TLB-01 at a mass ratio of 23:4:5 to obtain a viscosity-reducing superplasticizer for sleepers.

Embodiment 2

[0073] 49g of the polyether macromonomer (molecular weight is about 4000) prepared by referring to the example of CN109679086A with 2-vinyloxyethanol as the initiator and end-capped with m-toluene isocyanate was dissolved in 32.5g of water in a kettle, Add 0.06g hydrogen peroxide (30% by mass aqueous solution), then start dropwise adding a mixture of 3.2g acrylic acid, 0.12gL-ascorbic acid, and 0.22g mercaptopropionic acid. The dropwise addition time is 1h. After the dropwise addition, mature for 1.5h and cool After reaching room temperature, mother liquor B was obtained, and mixed with water-reducing mother liquor TL-01 and slump-preserving mother liquor TLB-01 at a ratio of 28:5:4 to obtain a viscosity-reducing superplasticizer for sleepers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com