Viscosity reduction reinforcing agent for concrete and application thereof

A technology for concrete and reinforcing agent, applied in the field of viscosity reducing and reinforcing agent for concrete, can solve the problems of increased shear stress, poor workability of concrete, excessive pumping pressure, etc., to reduce yield shear stress, improve strength, and reduce viscosity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

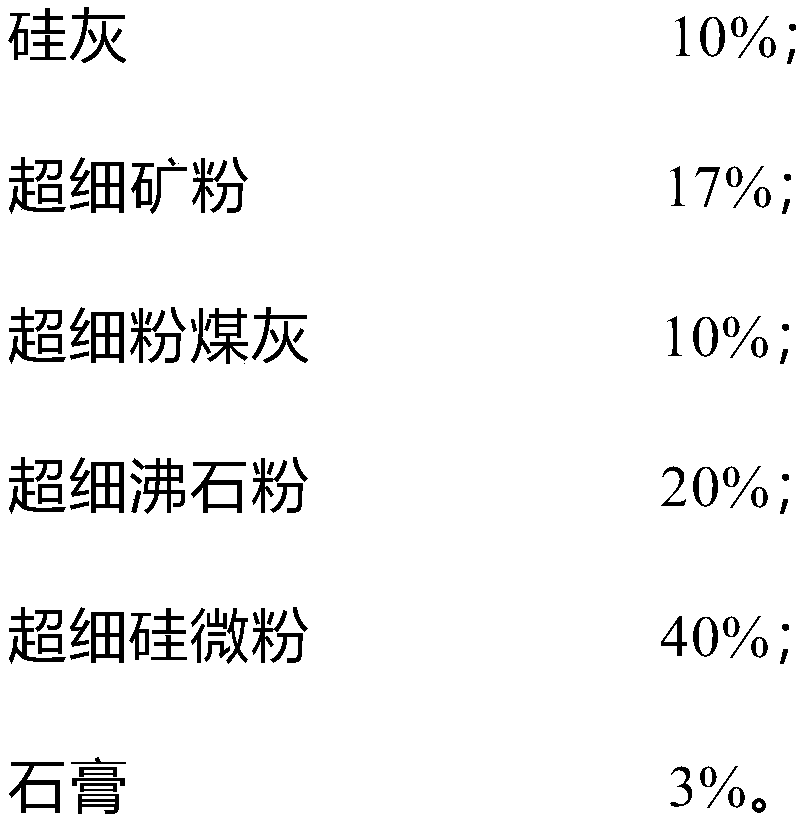

[0027] A concrete viscosity-reducing reinforcing agent is composed of the following substances by mass percentage:

[0028]

[0029] The addition amount of the viscosity-reducing reinforcing agent for concrete accounts for 5% of the mass of the cementitious material.

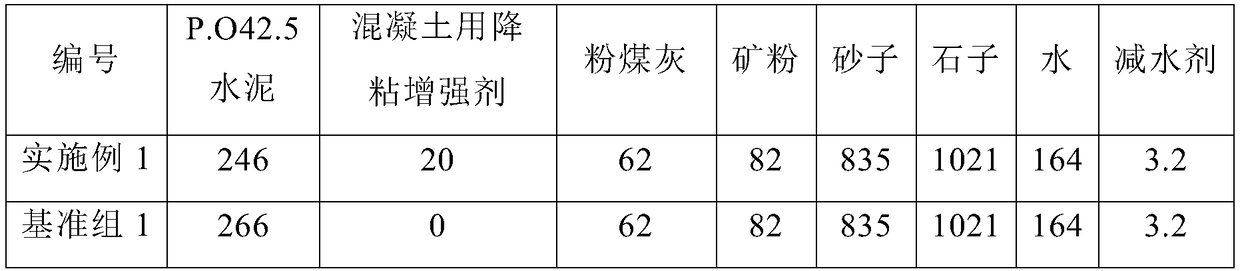

[0030] Concrete raw material composition of benchmark group 1: cement is BBMG P.O 42.5, fly ash is grade II fly ash, mineral powder is grade S75 mineral powder, sand is machine-made sand with a fineness modulus of 2.9, and gravel is graded from 5mm to 25mm Crushed stone, the admixture is polycarboxylate high-performance water reducer.

[0031] Table 1 C40 mix ratio (kg / m 3 )

[0032]

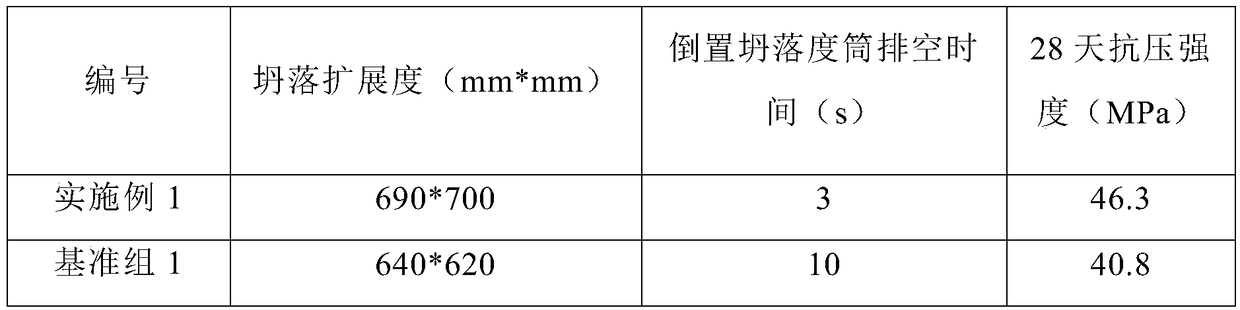

[0033] Table 2 C40 performance test results

[0034]

Embodiment 2

[0036] A concrete viscosity-reducing reinforcing agent is composed of the following substances by mass percentage:

[0037]

[0038] The added amount of the viscosity-reducing reinforcing agent for concrete accounts for 8% of the mass of the cementitious material.

[0039] Concrete raw material composition of benchmark group 2: cement is BBMG P.O 42.5, fly ash is Class I fly ash, mineral powder is S95 grade mineral powder, sand is river sand with a fineness modulus of 2.4, and gravel is graded from 5mm to 20mm Crushed stone, the admixture is polycarboxylate high-performance water reducer.

[0040] Table 3 C55 mix ratio (kg / m 3 )

[0041]

[0042] Table 4 C55 performance test results

[0043]

Embodiment 3

[0045] A concrete viscosity-reducing reinforcing agent is composed of the following substances by mass percentage:

[0046]

[0047]

[0048] The added amount of the viscosity-reducing reinforcing agent for concrete accounts for 10% of the mass of the cementitious material.

[0049] Concrete raw material composition of benchmark group 3: cement is Yinghai P.O 42.5, fly ash is class II fly ash, slag powder is S95 slag powder, silica fume is 87% silica content, sand is fineness modulus 2.7 mechanism Sand and gravel are graded crushed stones of 5mm to 20mm, and the admixture is polycarboxylate high-performance water reducer.

[0050] Table 5 C60 mix ratio (kg / m 3)

[0051]

[0052] Table 6 C60 performance test results

[0053]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com