A high pressure washer

A technology of a high-pressure cleaner and a high-pressure plunger pump, which is applied to cleaning methods and appliances, cleaning methods using liquids, chemical instruments and methods, etc., and can solve the impact on the life of the spray gun connecting pipe, bursting of the connecting pipe and the spray gun, and operator injury and other problems to achieve the effect of improving service life, reducing pumping pressure and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

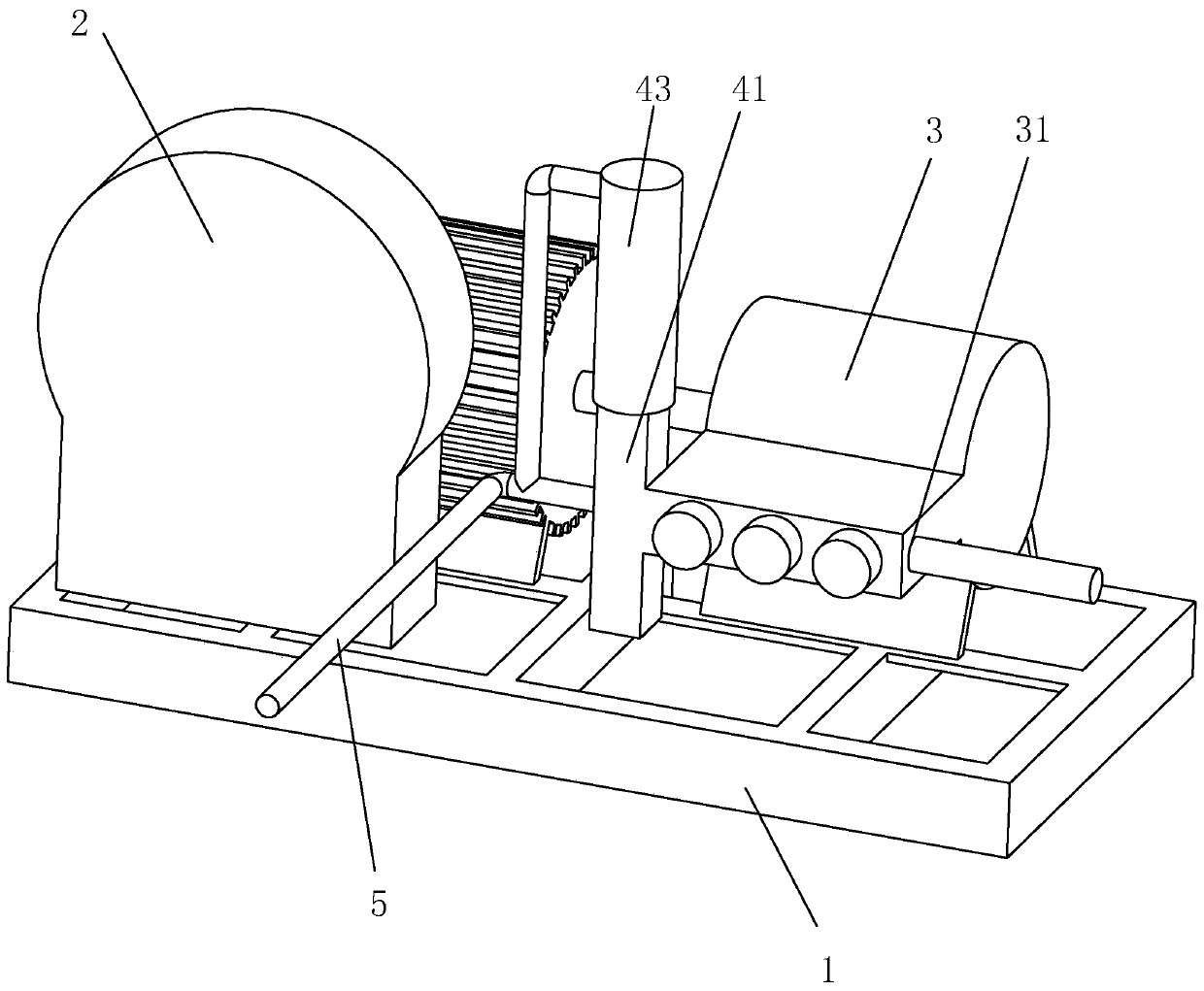

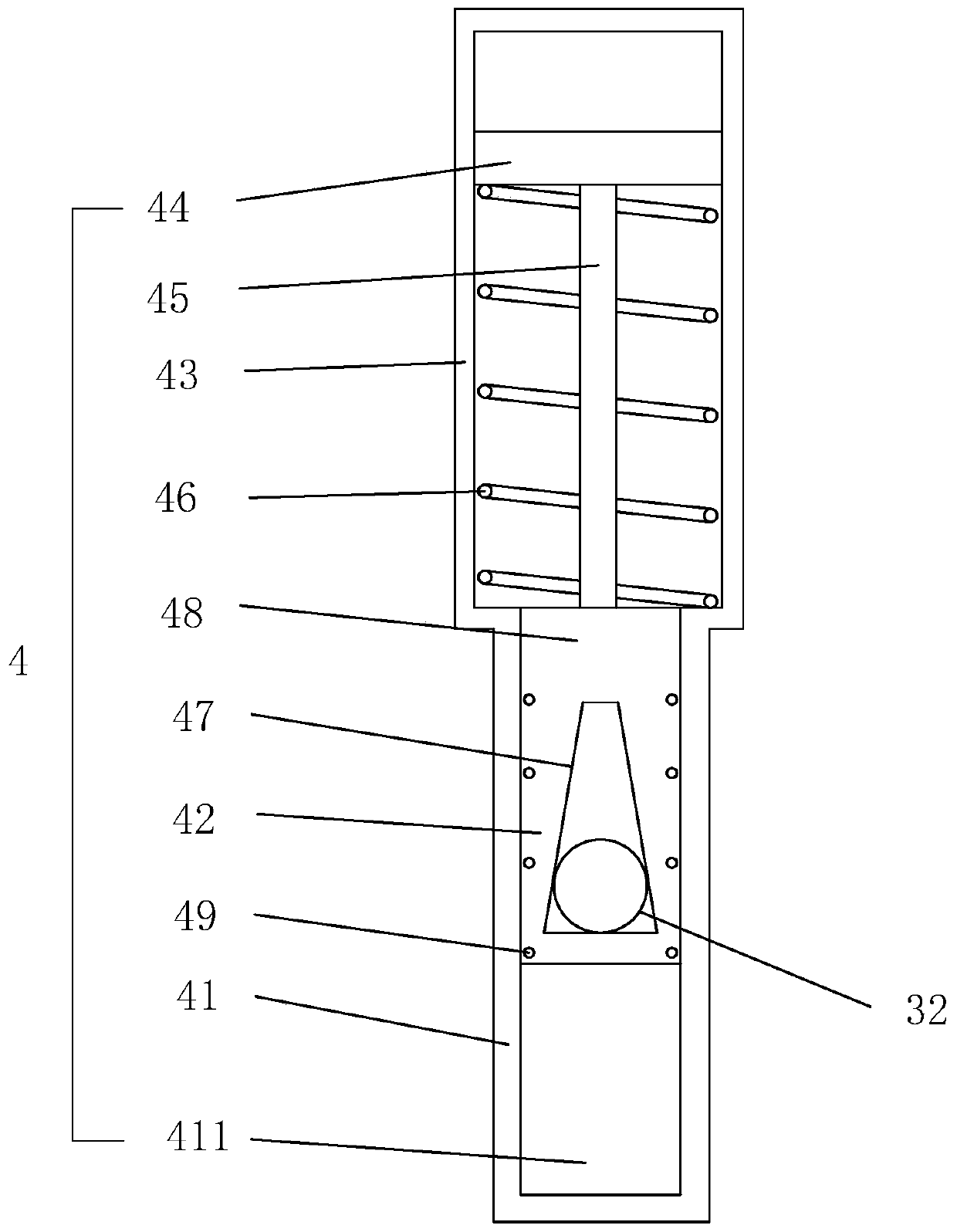

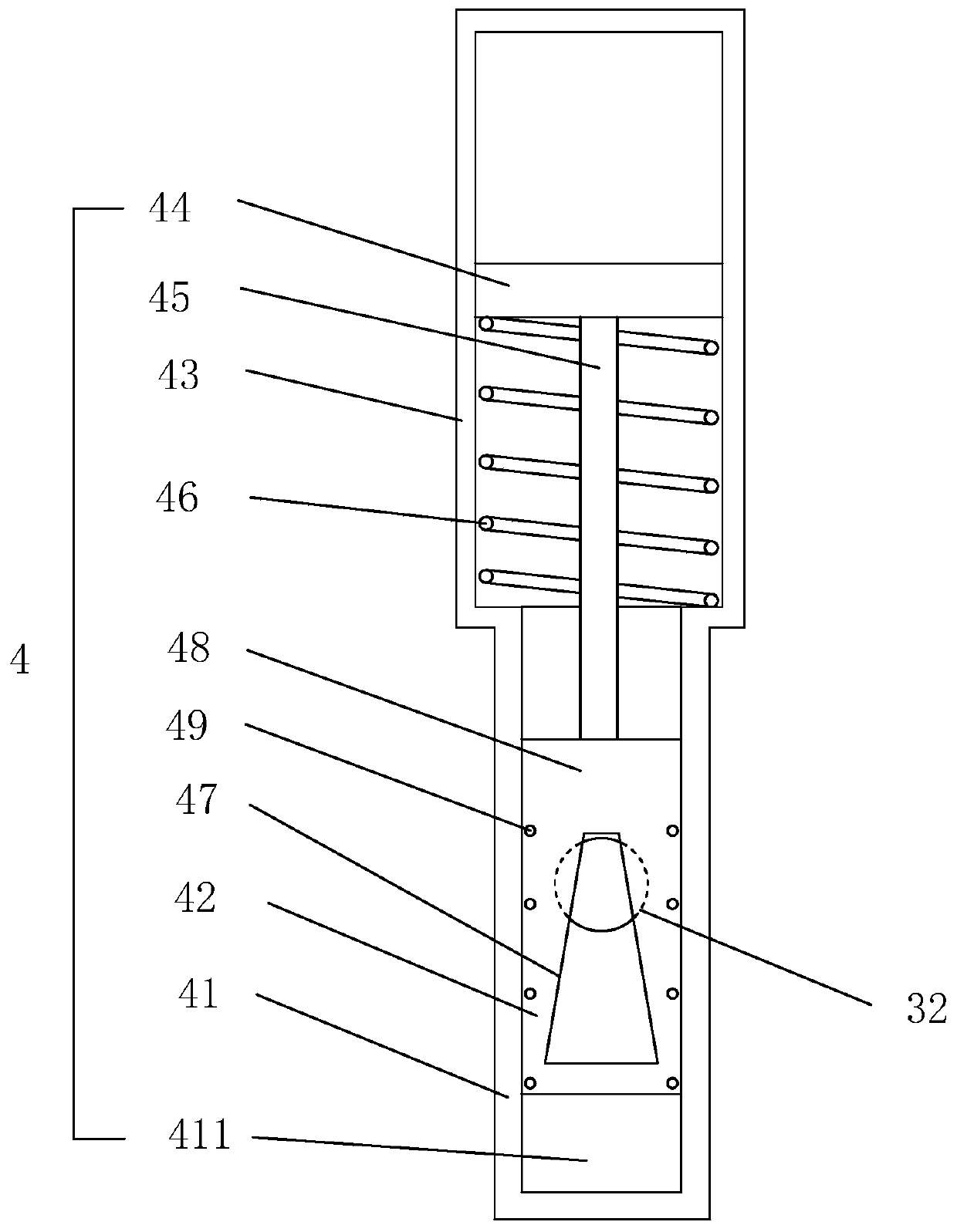

[0038] Example 1: A high-pressure cleaner, such as figure 1 , 2 As shown, including the base 1, the control box 2, the high-pressure plunger pump 3, the nozzle, the control box 2, the high-pressure plunger pump 3 are all fixedly connected to the base 1 by bolts, and the control box 2 controls the high-pressure plunger pump 3 The opening and closing of the high-pressure plunger pump 3 can be directly detected through the control box 2 to automatically adjust the pressure of the high-pressure plunger pump 3. The nozzle end is connected to the high-pressure plunger pump through the connecting pipe 5 3 connection, people operate the switch on the nozzle to spray water, and people can operate the nozzle to flush and clean the device. The high-pressure plunger pump 3 is provided with a water inlet 31 and a water outlet 32, and the water enters the high pressure through the water inlet 31 The plunger pump 3 presses water into the connecting pipe 5 through the water outlet 32 through ...

Embodiment 2

[0043] Embodiment 2: A high-pressure cleaner, which differs from embodiment 1 in that Figure 5 As shown, the base 1 is provided with a centrifugal pump 6 and a water storage tank 7, the centrifugal pump 6 is connected to the water storage tank 7, the water inlet 31 is connected to the water storage tank 7, and the top of the water storage tank 7 is provided with an exhaust valve 71.

[0044] The centrifugal pump 6 pumps external water into the water storage tank 7 for storage and filtration, so that the high-pressure plunger pump 3 can directly pump water from the water storage tank 7, so as to prevent external debris from affecting the normal operation of the high-pressure plunger pump 3 Work, and the delivery force generated by the high-pressure plunger pump 3 is all acting on pressing water into the connecting pipe 5, thereby effectively improving the water-pressing effect of the high-pressure plunger pump 3. When the centrifugal pump 6 pumps the water to the water storage tan...

Embodiment 3

[0046] Embodiment 3: A high-pressure cleaner, the difference from embodiment 2 is that Figure 7 , 8 As shown, the base 1 is provided with a fixed ring 81, the fixed ring 81 is fixedly connected with a supporting foot 82, the supporting foot 82 is fixedly connected to the base 1, and the inner circumferential side of the fixed ring 81 is in contact with the outer circumferential side of the water storage tank 7. A cushion rubber pad 83 is also provided on the inner circumferential side of the fixing ring 81.

[0047] Since the water storage tank 7 basically plays an intermediate role and will filter debris, etc., the water storage tank 7 needs to be disassembled and cleaned frequently. Therefore, the water storage pipe is separated from the high-pressure plunger pump 3 and the centrifugal pump 6 It can be pulled out vertically from the fixing ring 81, and after cleaning, it can be fixed by inserting it into the fixing ring 81, thereby facilitating the disassembly and installation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com