Oil phase for medium-low temperature sensitization process emulsion explosive and prepared from coal-to-oil intermediate product and preparation method thereof

A technology of emulsified explosives and coal-to-oil, applied in explosives, non-explosive/non-thermal agent components, offensive equipment, etc., can solve the problems of oil phase material quality fluctuation, resource waste, impact, etc., and achieve good safety performance and fluidity Good, low pumping pressure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

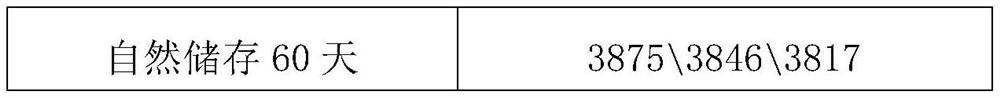

[0014] A method for preparing an oil phase for medium and low temperature sensitized emulsion explosives from coal-to-oil intermediates, comprising mixing coal-to-oil intermediates, wax materials, sp-80 emulsifiers, polymer surfactants, and the weight ratio of the four materials Between 45-55:15-20:25-30:5-10, the four materials are metered into the mixing tank, heated and stirred for 40-70 minutes, and the temperature is controlled at 75±5°C to form a composite oil phase.

[0015] Coal-to-liquid intermediate product is a coal chemical technology that uses coal as raw material to produce liquid fuel and chemical raw materials. The index of coal-to-oil intermediate product is 100°C kinematic viscosity of 8-12mm 2 / s, 20℃ density 750~850kg / m 3 , freezing point 0-10°C, flash point > 170°C, n-alkanes ≥ 92%, aromatics content ≤ 0.3%, sulfur content ≤ 4.0mg / kg. The most notable feature of coal-to-oil intermediates is that the product is mainly composed of straight-chain hydrocarbon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Solidifying point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com