Device for measuring gas loss in gas storage injection and production process

A technology of gas loss and gas storage, which is applied in the field of experimental devices, can solve the problems of poor experimental flexibility, large errors, and inability to orientate continuous simulation, etc., and achieve the effect of easy realization and small errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

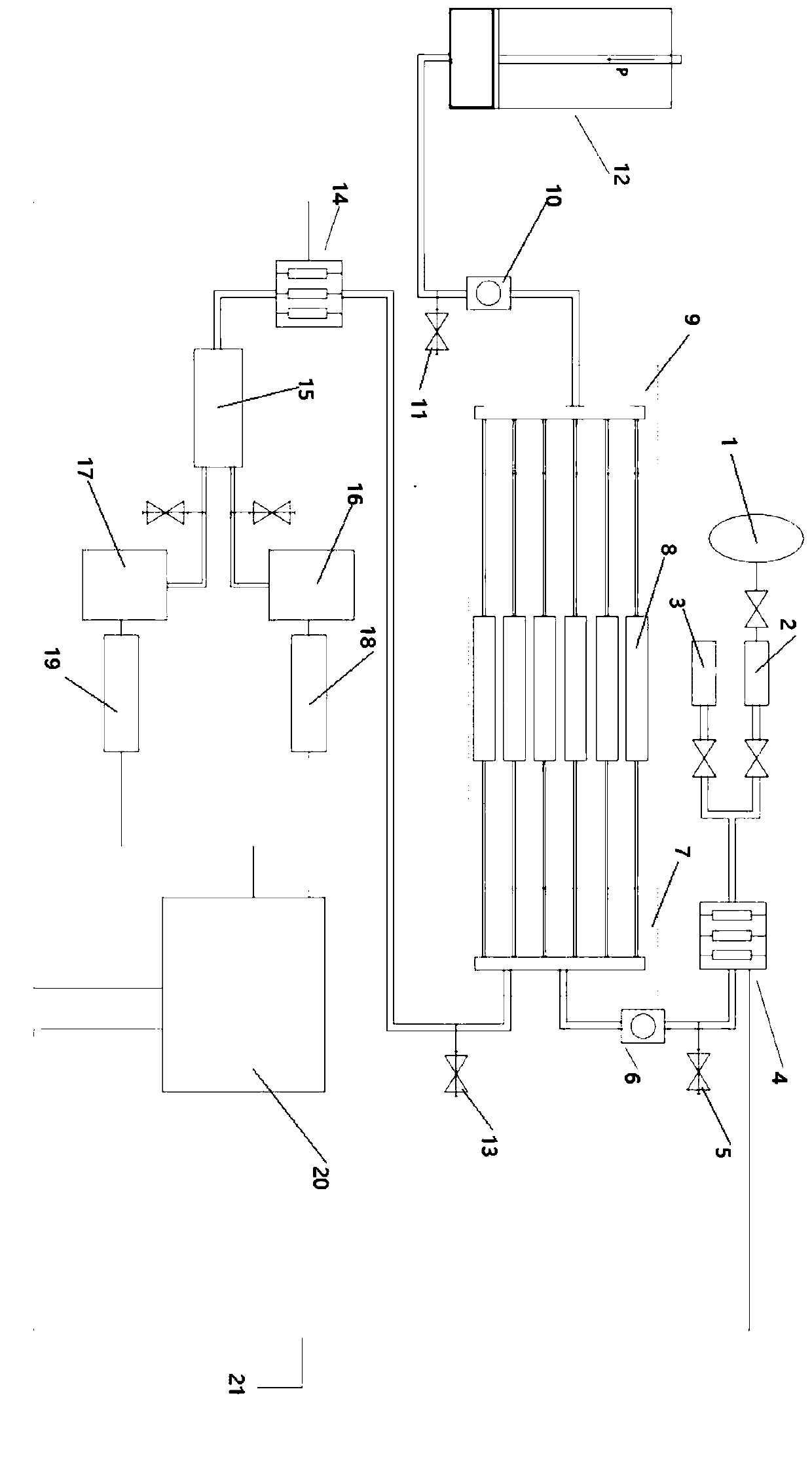

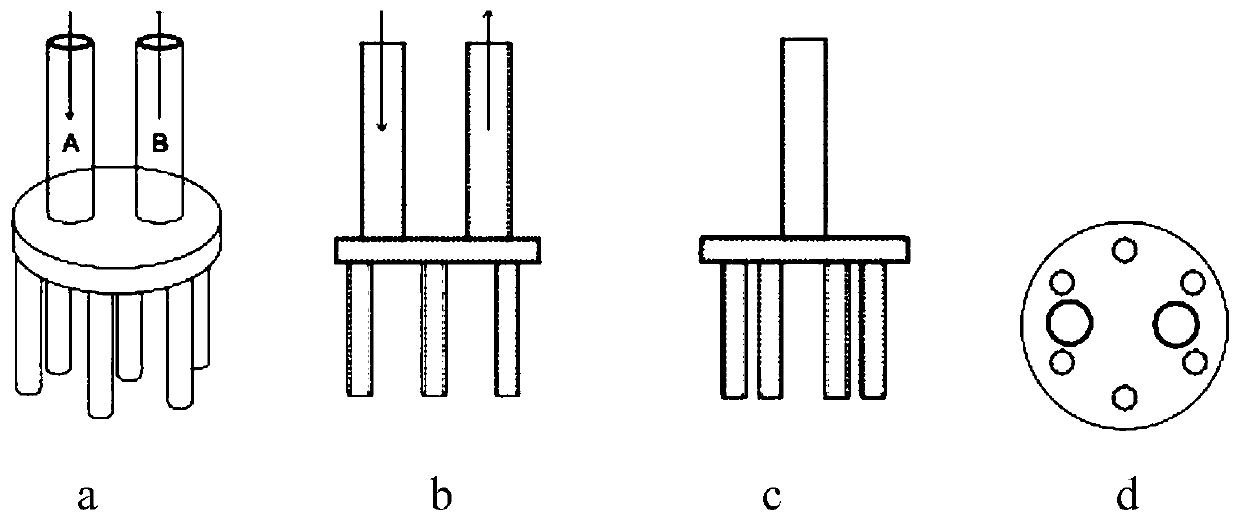

[0034] refer to Figure 1-4 , Put the small core of the experimental sample into the small core holder, according to the purpose of the experiment, refer to Figure 3 to combine the clamping units, and install them into the total experimental device. This device can carry out 6 groups of experiments at most at the same time, according to the purpose requirement of experiment, the experiment of 6 groups or less can seal up the superfluous conduit in the structure of total conduit two-way component device 7 and small conduit one-way inlet device 9.

[0035] The specific working steps of the device for measuring gas loss during injection and production of the gas storage are as follows:

[0036] 1. Turn on the air pump 1, and pass the experimental gas through the conduit through the pressure sensor I in turn to stabilize it at 20MPa.

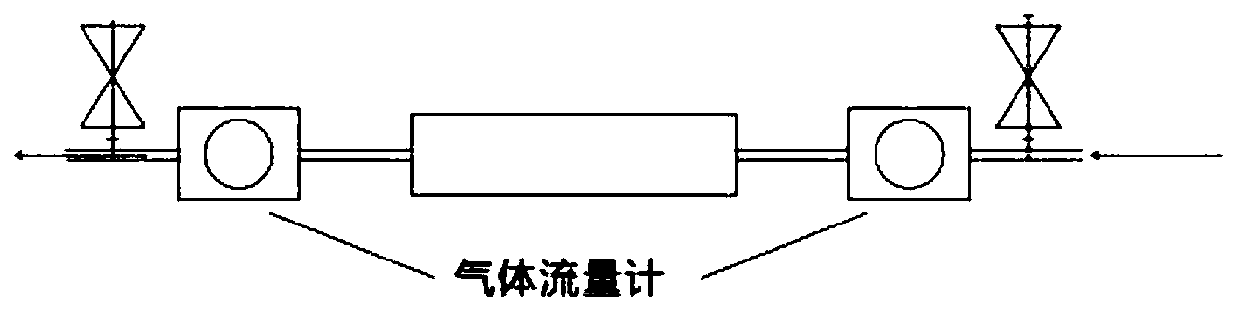

[0037] 2. Open the valve a5 and the valve b11, the experimental gas enters the two-way component device 7 of the main conduit through the gas flow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com