Online centralized detection and management device utilizing OTDR

A management equipment and centralized technology, applied in the field of OTDR, can solve the problems of unstable current signal frequency, easy loosening at the connection port, and not supporting temperature detection, so as to ensure the tightness, improve the detection items, and prevent the optical fiber from overheating. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

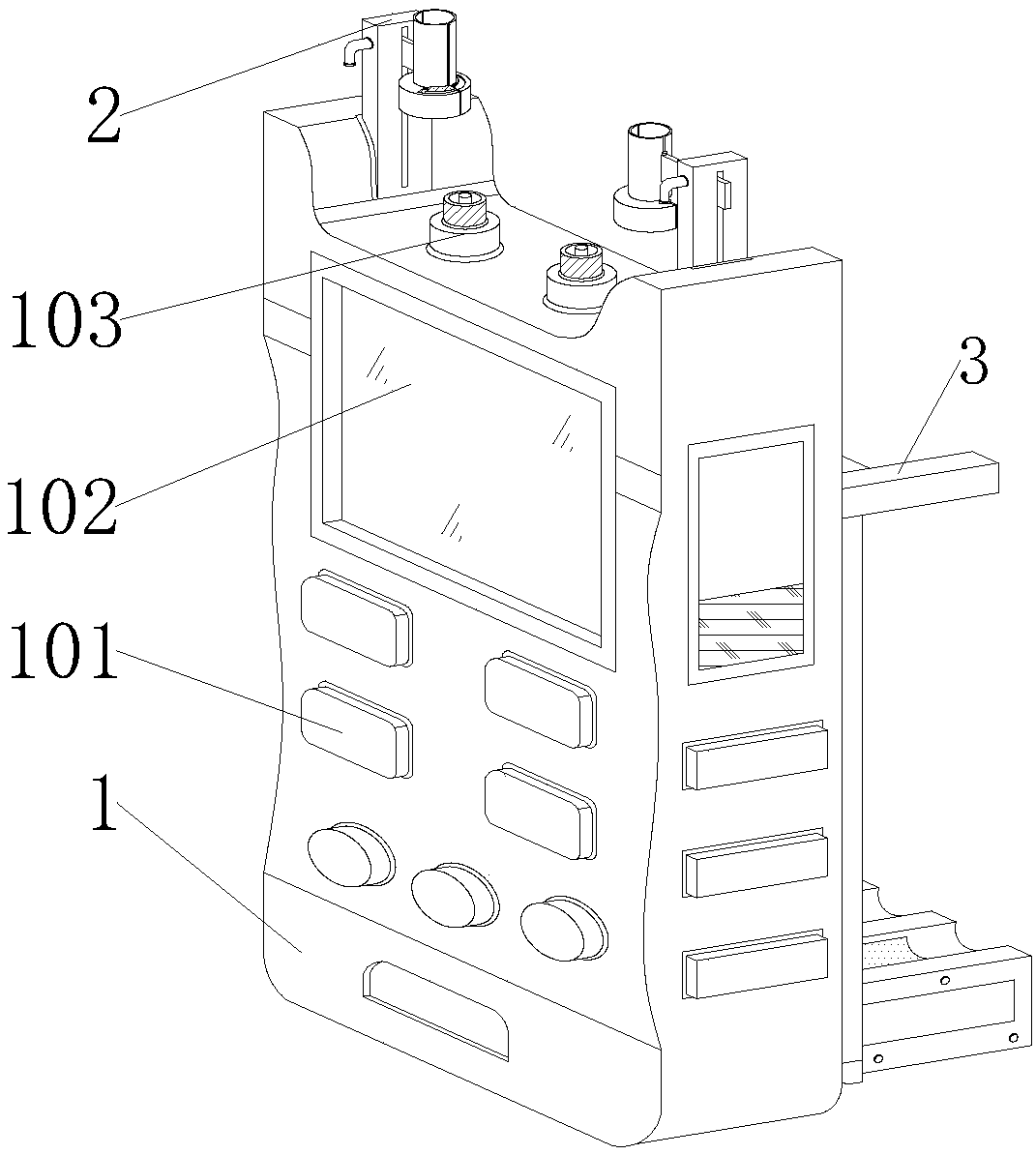

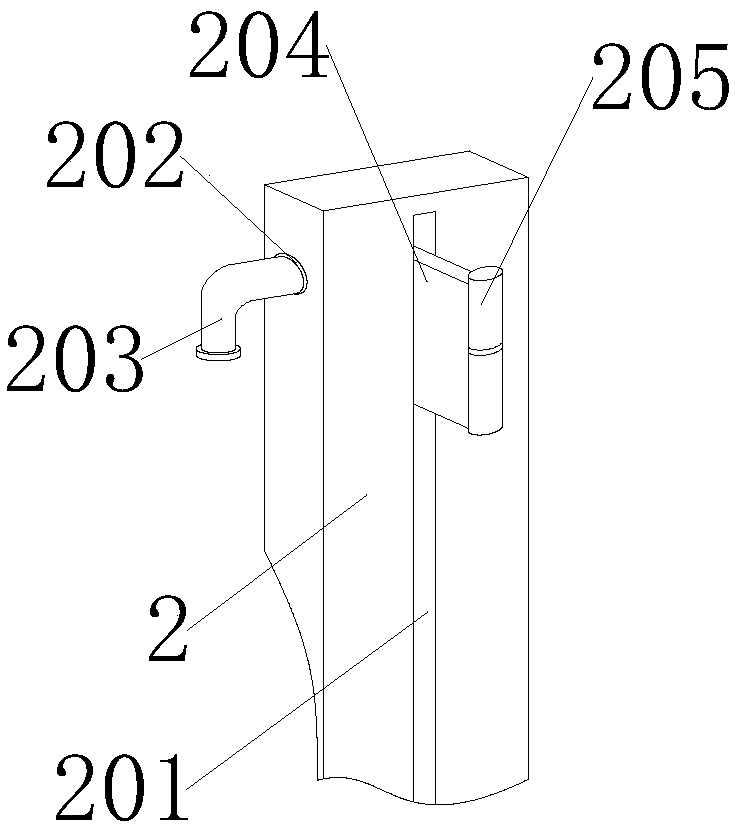

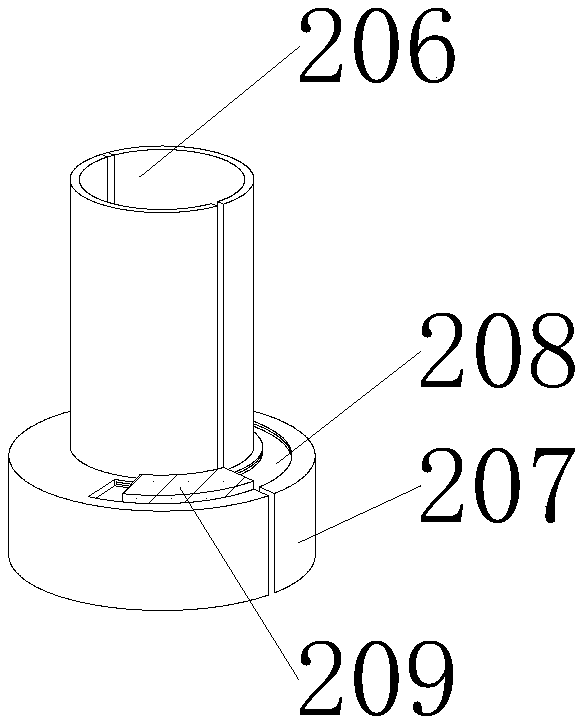

[0021] see Figure 1-5 As shown, an online centralized detection and management equipment using OTDR, the online centralized detection and management equipment using OTDR includes an optical time domain reflectometer 1 and a fixed plate 2, and the left and right sides of the top inner wall of the optical time domain reflectometer 1 are fixedly connected with fixed Board 2; the top of the optical time domain reflectometer 1 is electrically connected to the optical fiber interface 103 inside the fixed board 2, and the front end of the fixed board 2 has a movable groove 201, and the upper left side of the fixed board 2 has a small hole 202, and the small hole 202 and the movable groove 201 communicate with each other, the inside of the small hole 202 is rotatably connected with the card shaft 203, and the inside of the movable groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com