Easy-to-clean fluid bed granulator and cleaning method thereof

A boiling granulator and easy-to-clean technology, applied in cleaning methods and utensils, chemical instruments and methods, cleaning hollow objects, etc., can solve the problems of inadequate cleaning, long cleaning time, and complicated cleaning steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

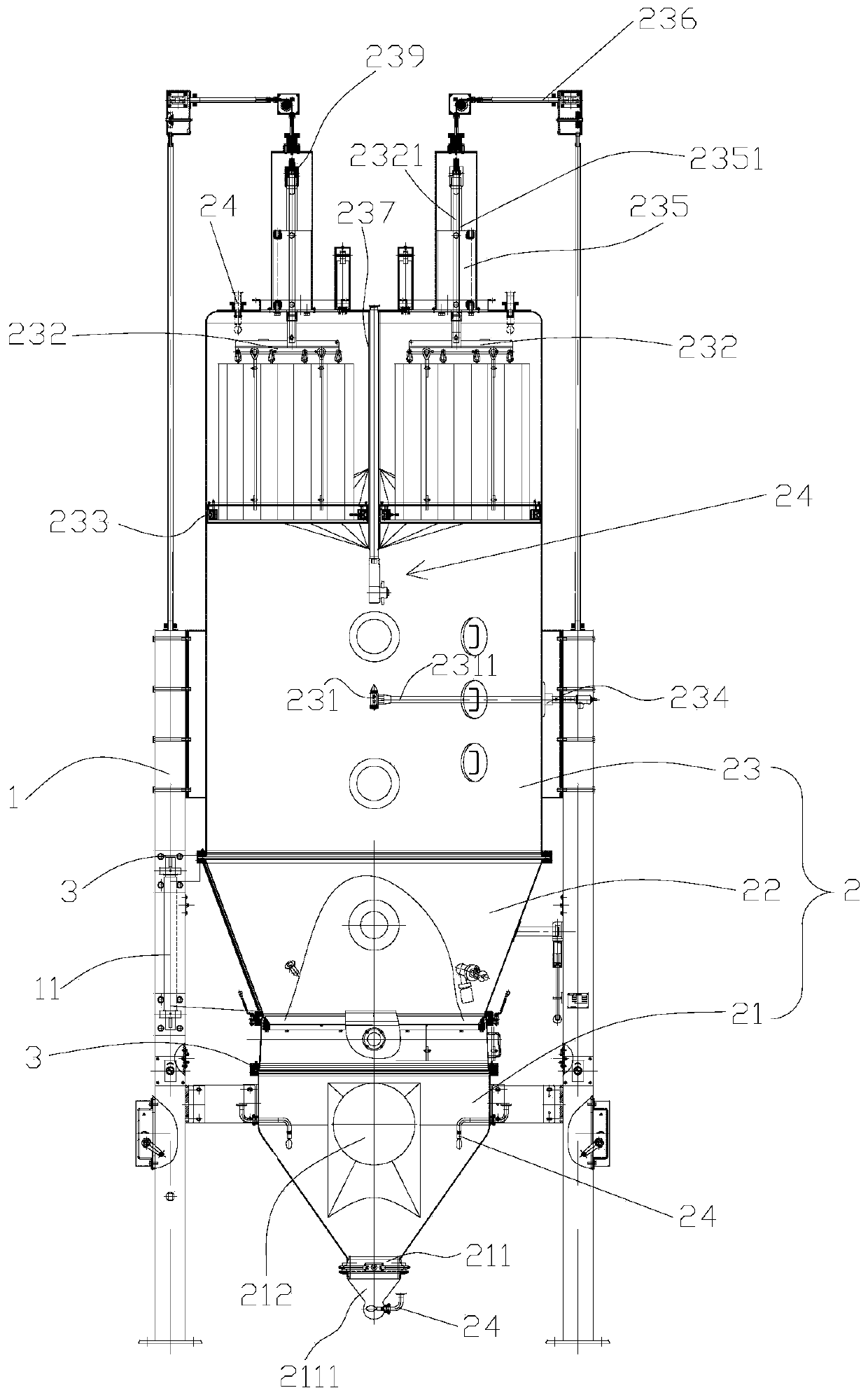

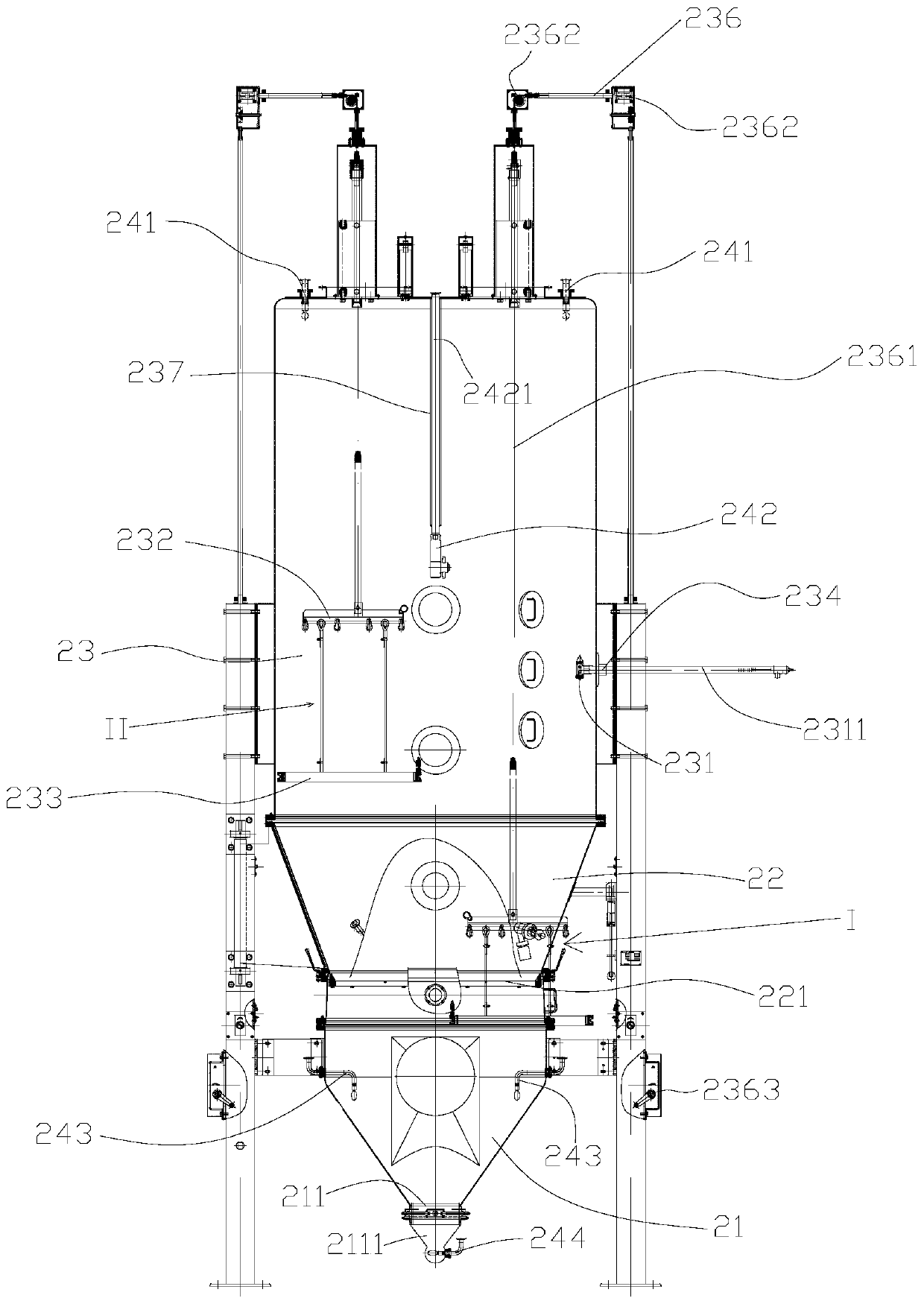

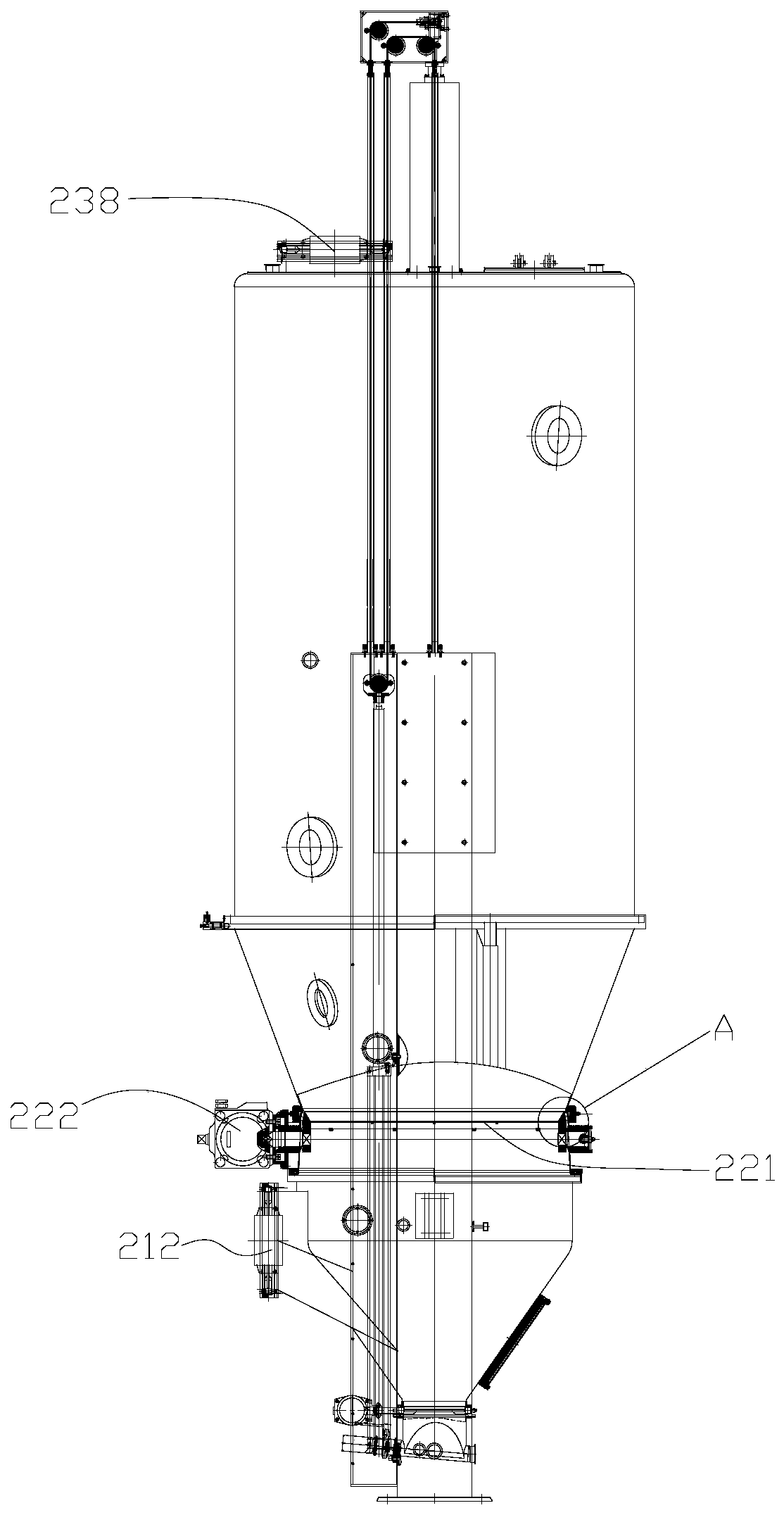

[0029] Specific embodiments of the present invention such as Figure 1-4As shown, an easy-to-clean fluidized granulator includes a frame 1 on which a granulation tank 2 is arranged, and the granulation tank 2 is sequentially provided with a base buffer bucket 21 from bottom to top , the material container 22 and the diffusion and trapping chamber 23, the base buffer bucket 21, the material container 22 and the diffusion and trapping chamber 23 are hermetically connected to each other through the first sealing member 3, and the material container 22 is hinged by the hinge shaft 11 Arranged on the frame 1, the first sealing member 3 is an annular inflatable airbag. The base buffer bucket 21 is provided with an air inlet 212, and the upper end of the diffusion and collection chamber 23 is provided with an air outlet 238, and the diffusion and collection chamber 23 is provided with an atomizing spray gun 231, several shaking bag holders 232 and fixed The air bag frame 233 on each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com