A grate sieve plate for vibrating sieve and vibrating sieve

A technology of grate sieve plates and vibrating screens, which is applied in the fields of filtration, solid separation, chemical instruments and methods, etc., can solve problems such as short service life, low screening precision, and difficulty in cleaning materials, and achieve long service life and reduce The effect of cleaning difficulty and improving screening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

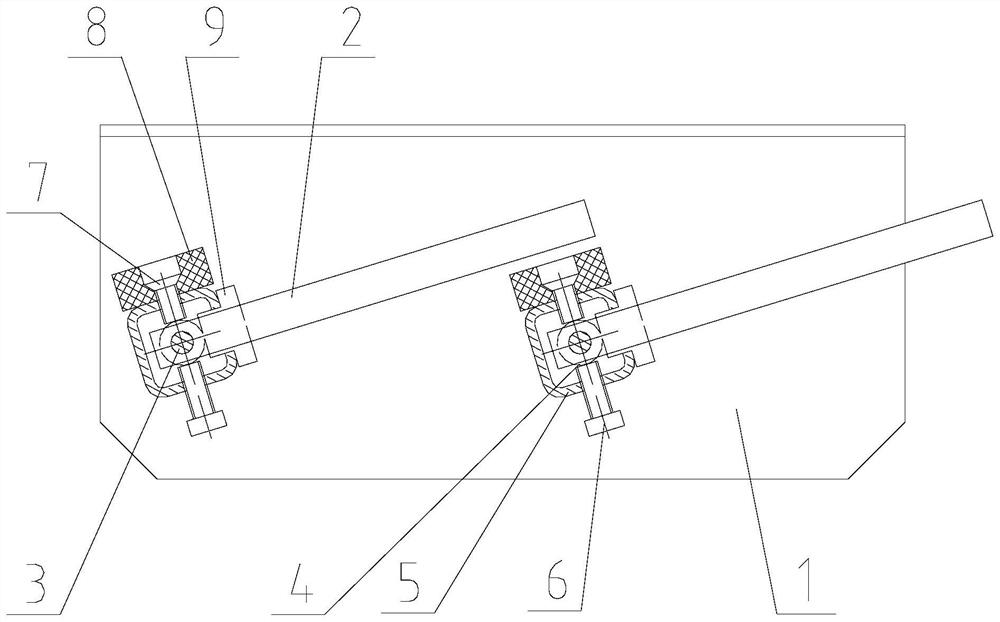

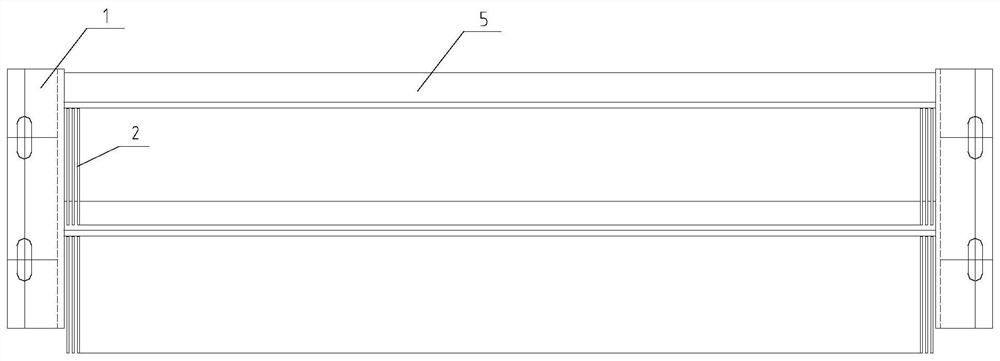

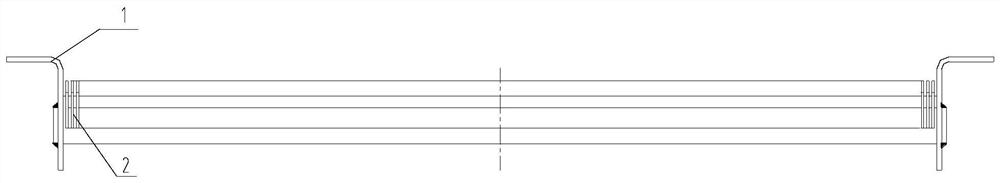

[0027] refer to figure 1 , figure 2 with image 3 , a grate sieve plate for a vibrating screen of the present invention, comprising two side plates 1 and a plurality of grate sieve units installed between the two side plates 1, the grate sieve unit comprising a grate bar series assembly and a plurality of The grate bar 2, the grate bar series assembly includes the shaft 3, the spacer 4, the C-shaped groove 5 and the bolt 6, one end of the grate bar 2 is drilled, and the grate bar 2 and the spacer 4 are connected by two grate bars. The strips 2 are connected in series on the shaft 3 in the form of separating the spacer 4, and then installed in the C-shaped groove 5 as a whole. A bolt 6 is set on the C-shaped groove 5 of the C-shaped groove 5, and the upper end of the bolt 6 is supported on the spacer 4. Both ends of the C-shaped groove 5 and the shaft 3 are fixed on the two side plates 1, and the opening of the C-shaped groove 5 faces upward. Tilt at a certain angle; the un...

Embodiment 2

[0036] Different from Example 1, refer to Figure 4 , the side plate 1 is fixedly connected by a plurality of side plate units, two grate sieve units are arranged between each two corresponding side plate units, and the entire grate sieve plate is arranged inclined downward. The advantage of this embodiment is that the length of the grate sieve plate can be flexibly set according to the length required by the vibrating screen.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com