Wood-plastic composite material using silane-modified boehmite as flame retardant and preparation method thereof

A wood-plastic composite material and silane modification technology, applied in the field of wood-plastic composite material and its preparation, can solve the problems of affecting the processing performance and mechanical properties of materials, large addition amount, etc., and achieve the enhancement of thermal conductivity, tensile strength, The effect of improving flame retardant properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

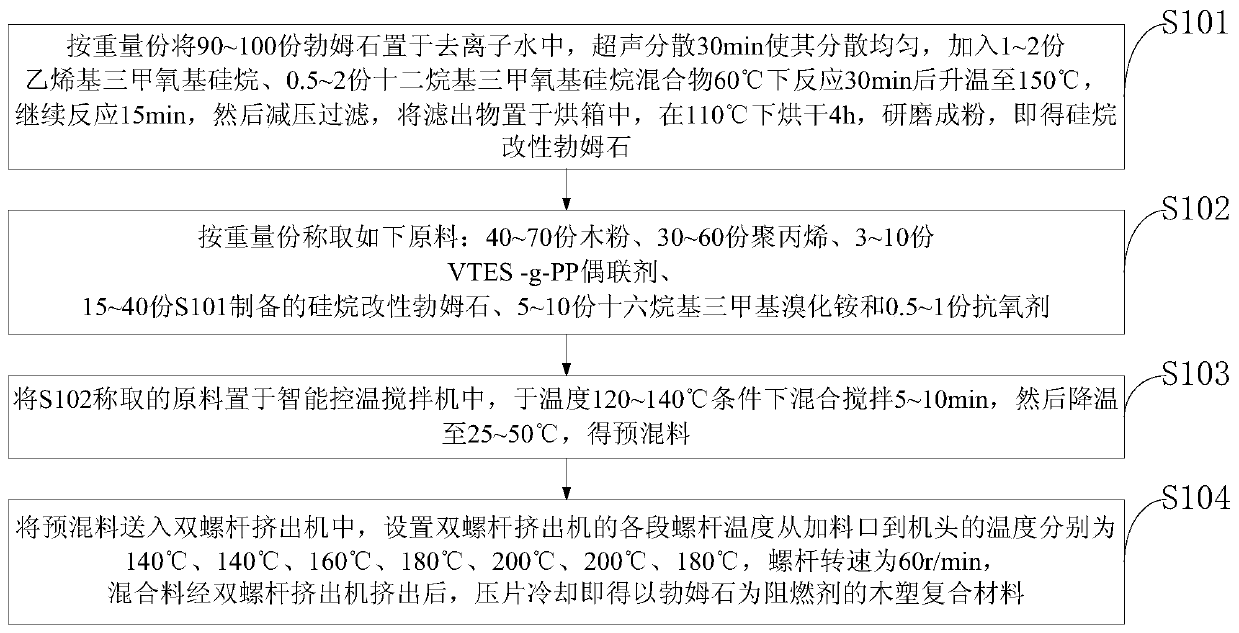

[0028] like figure 1 As shown, the preparation method of the wood-plastic composite material using silane-modified boehmite as a flame retardant provided by the embodiment of the present invention includes the following steps:

[0029] S101. Put 90-100 parts of boehmite in deionized water by weight, disperse it by ultrasonic for 30 minutes to make it evenly dispersed, add 1-2 parts of vinyltrimethoxysilane, 0.5-2 parts of dodecyltrimethoxy React the silane mixture at 60°C for 30 minutes, then raise the temperature to 150°C, continue to react for 15 minutes, then filter under reduced pressure, put the filtrate in an oven, dry at 110°C for 4 hours, and grind it into powder to obtain silane-modified boehmite ;

[0030] S102. Weigh the following raw materials by weight: 40-70 parts of wood flour, 30-60 parts of polypropylene, 3-10 parts of VTES-g-PP coupling agent, 15-40 parts of silane-modified boehmite prepared by S101 , 5-10 parts of cetyltrimethylammonium bromide and 0.5-1 p...

Embodiment 1

[0035] The wood-plastic composite material using silane-modified boehmite as a flame retardant provided by the embodiment of the present invention consists of 60 parts of wood powder, 40 parts of polypropylene, 6 parts of VTES-g-PP coupling agent, 25 parts of Silane-modified boehmite, 8 parts cetyltrimethylammonium bromide and 1 part antioxidant.

Embodiment 2

[0037] The wood-plastic composite material using silane-modified boehmite as a flame retardant provided by the embodiment of the present invention consists of 60 parts of wood powder, 40 parts of polypropylene, 6 parts of VTES-g-PP coupling agent, 30 parts of Silane-modified boehmite, 8 parts cetyltrimethylammonium bromide and 1 part antioxidant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com