Post type transparent insulator for high-voltage line

A technology of transparent insulation and high-voltage lines, applied in the direction of insulators, supporting insulators, circuits, etc., can solve the problems of aging and falling off of iron-bound wires, potential safety hazards, and low temperature tolerance, so as to prevent serious ice and snow and blockage The effects of hysteresis arc series connection and enhanced insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

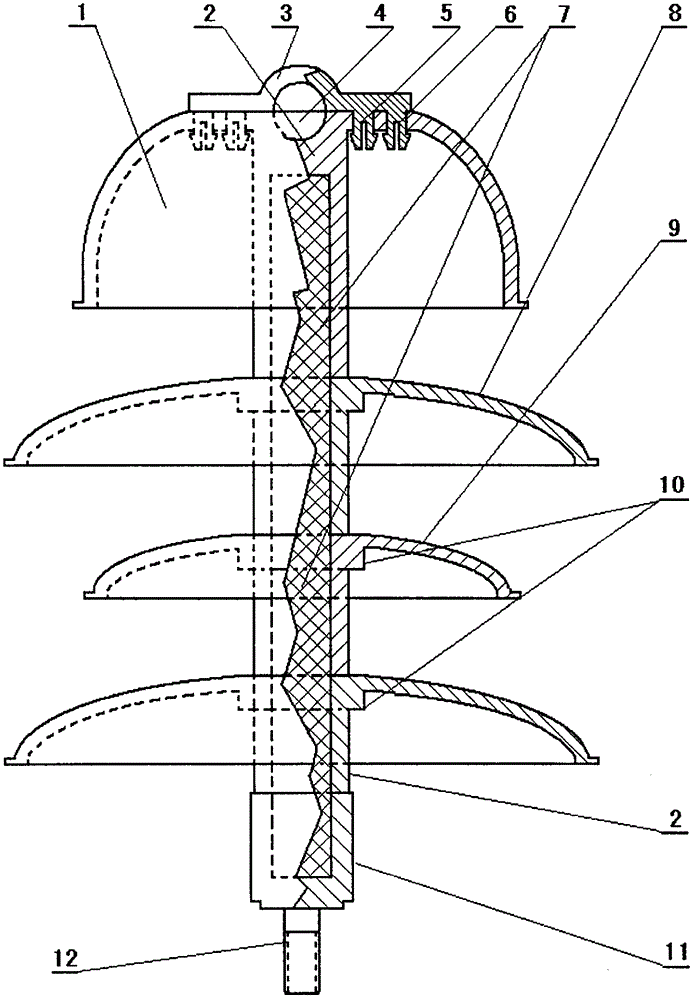

[0032] This high-voltage line column-type transparent insulator is provided with a pressure plate 3, a flat-top shed skirt 1, a flat-top shed skirt center tube 2, a large shed skirt 8, a small shed skirt 9, a connecting handle 7, a metal sleeve 11, and a support bolt 12. The pressure plate 3, the flat-top shed 1, the center tube 2 of the flat-top shed, the large shed 8, and the small shed 9 are made of polycarbonate; the connecting handle 7 is an epoxy resin handle, and the The metal sleeve 11 and the support bolt 12 are made of iron metal; the flat-top shed 1, the center tube 2 of the flat-top shed, the large shed 8 and the small shed 9 are injected into one body, and are inserted into the connecting handle 7 for bonding fixed; or first integrate the flat-top shed 1 and the center tube 2 of the flat-top shed The umbrella skirt 9 and the large umbrella skirt 8 are evenly inserted into the connecting handle 7 in turn and glued and fixed.

[0033] Further, the flat top umbrella...

Embodiment 2

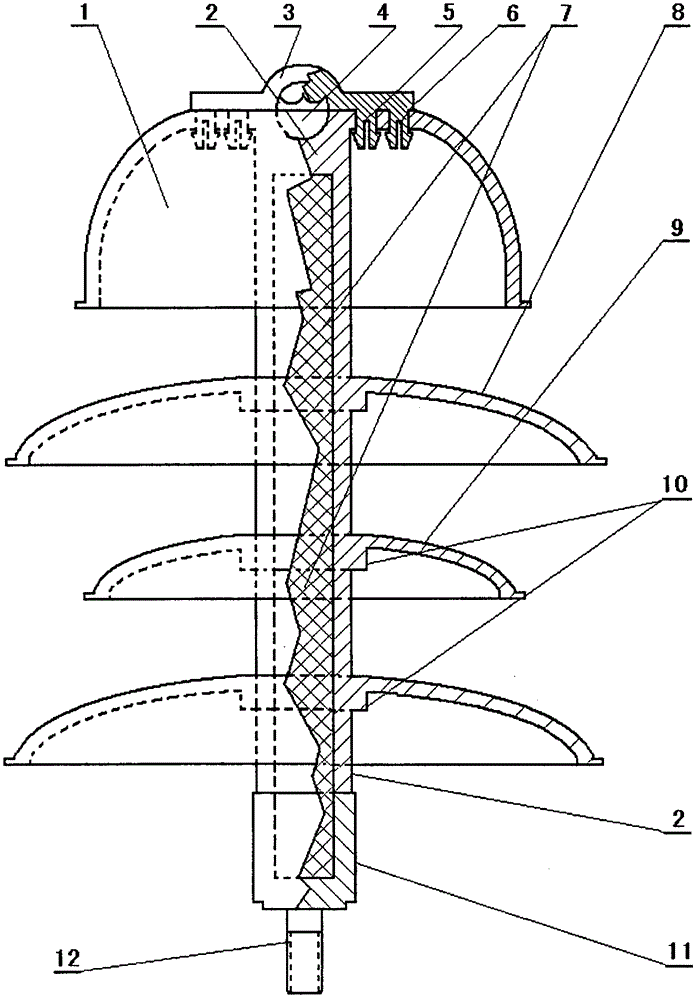

[0043] This high-voltage line column-type transparent insulator is provided with a pressure plate 3, a flat-top shed skirt 1, a flat-top shed skirt center tube 2, a large shed skirt 8, a small shed skirt 9, a connecting handle 7, a metal sleeve 11, and a support bolt 12. The pressure plate 3, the flat-top shed 1, the center tube 2 of the flat-top shed, the large shed 8, and the small shed 9 are made of polycarbonate; the connecting handle 6 is an epoxy resin handle, and the The metal sleeve 7 and the supporting bolt 8 are made of iron metal; the flat-top shed 1, the center tube 2 of the flat-top shed, the large shed 8, and the small shed 9 are injected into one body, and are inserted into the connecting handle 7 for bonding fixed; or first integrate the flat-top shed 1 and the center tube 2 of the flat-top shed The umbrella skirt 9 and the large umbrella skirt 8 are evenly inserted into the connecting handle 7 and fixed sequentially.

[0044] Further, the flat top umbrella sk...

Embodiment 3

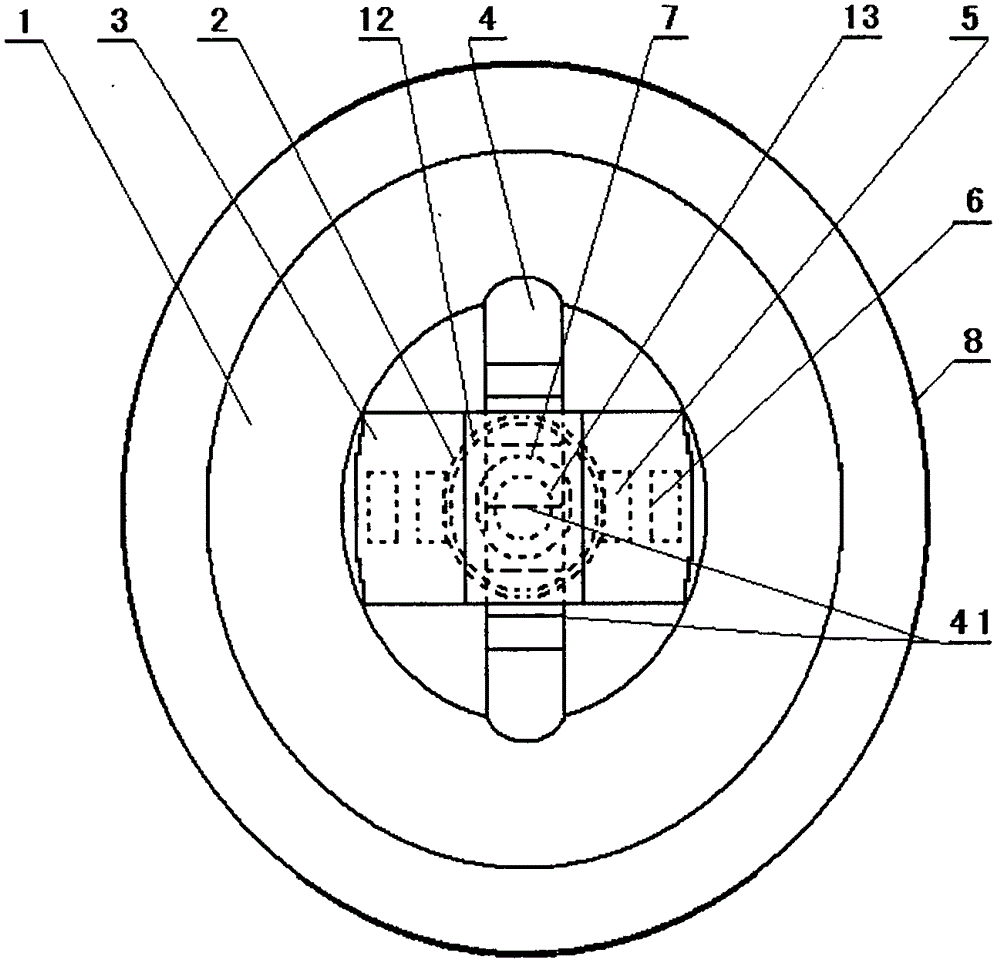

[0054] This high-voltage line column-type transparent insulator is provided with a pressure plate 3, a flat-top shed skirt 1, a flat-top shed skirt center tube 2, a large shed skirt 8, a small shed skirt 9, a connecting handle 7, a metal sleeve 11, and a support bolt 12. The pressure plate 3, the flat-top shed 1, the center tube 2 of the flat-top shed, the large shed 8, and the small shed 9 are made of polycarbonate; the connecting handle 7 is an epoxy resin handle, and the The metal sleeve 11 and the support bolt 12 are made of iron metal; the flat-top shed 1, the center tube 2 of the flat-top shed, the large shed 8 and the small shed 9 are injected into one body, and are inserted into the connecting handle 7 for bonding fixed; or first integrate the flat-top shed 1 and the center tube 2 of the flat-top shed The umbrella skirt 9 and the large umbrella skirt 8 are evenly inserted into the connecting handle 7 and fixed sequentially.

[0055] Further, the flat top umbrella skir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com