Pin-type transparent insulator

A transparent insulation, pin-type technology, applied in the direction of pin-type insulators, etc., can solve the problems of unstable wire fixation, aging and falling off of iron binding wires, high labor intensity of workers, etc., to prevent arc chain connection and reduce installation workload. , the effect of preventing severe ice and snow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

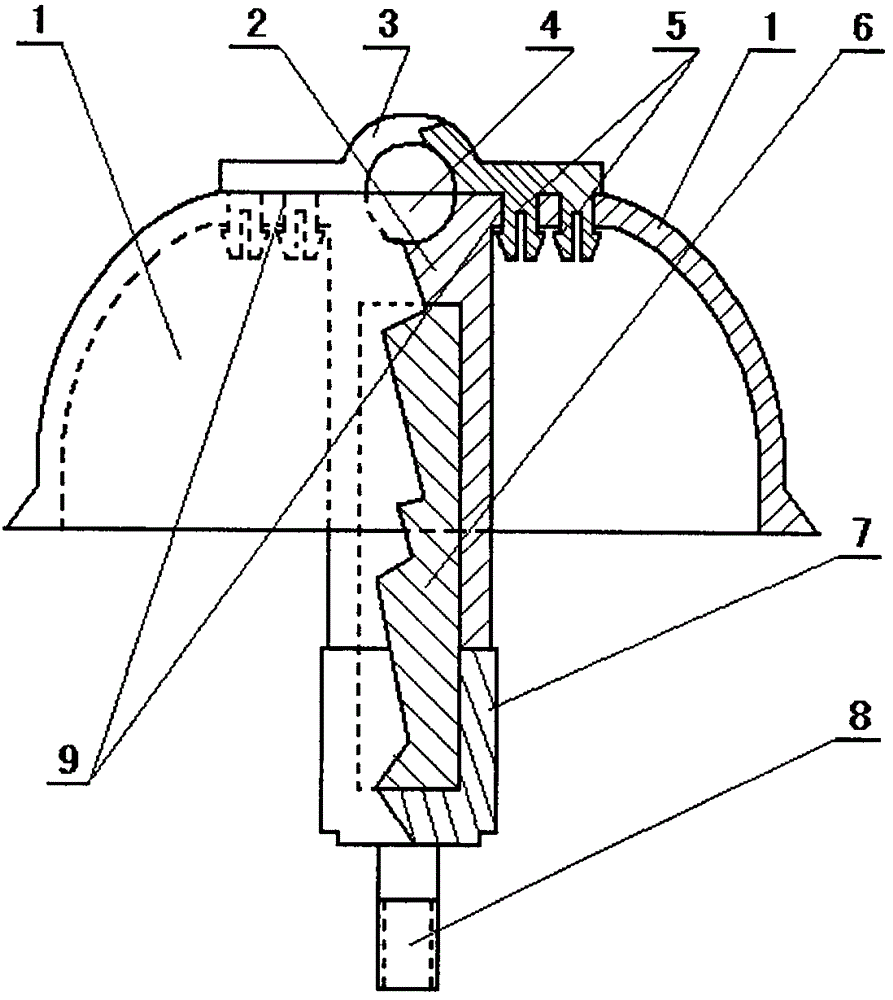

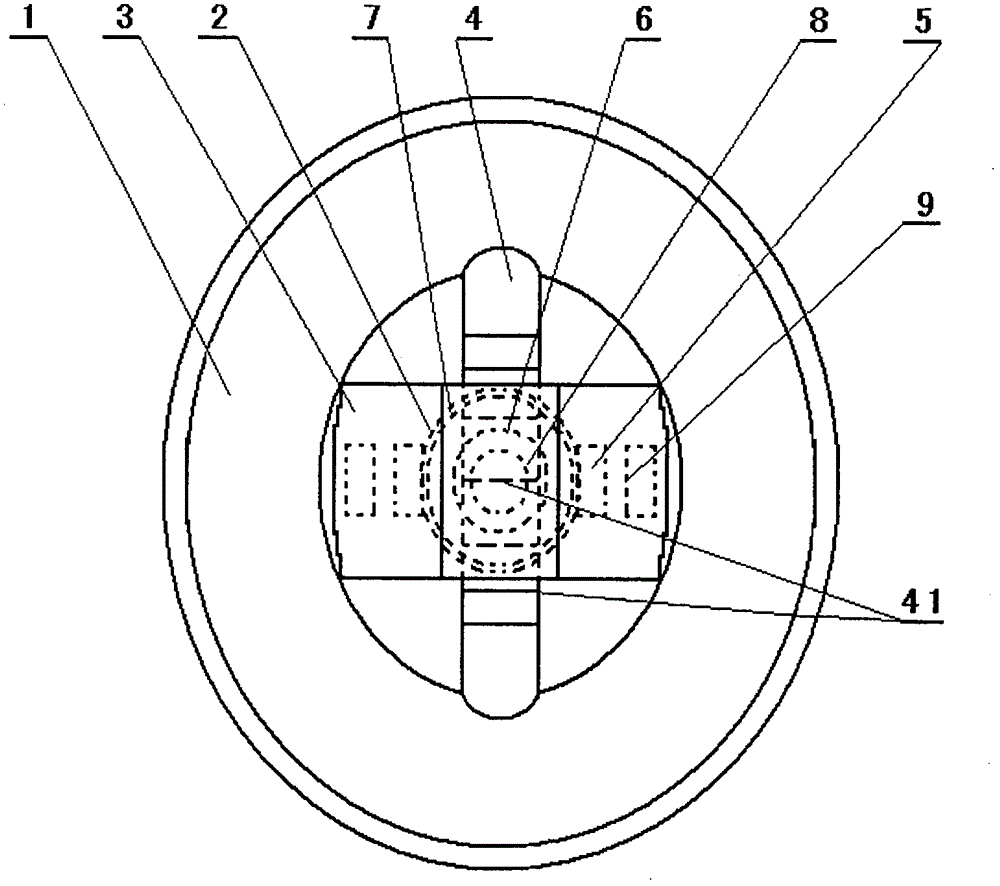

[0027] The needle-type transparent insulator is provided with a flat-top shed skirt 1, a flat-top shed skirt central tube 2, a pressure plate 3, a connecting handle 6, a metal sleeve 7, and supporting bolts 8. The above-mentioned pressure plate 3, flat-top shed skirt 1, Flat-top umbrella skirt central tube 2, connecting handle 6, metal sleeve 7, support bolt 8 are connected in sequence.

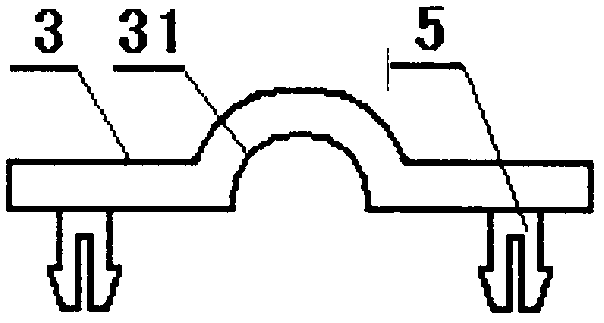

[0028] Further, the pressure plate 3, the flat-top shed 1 and the flat-top shed central tube 2 are made of polycarbonate, the thickness of the flat-top shed 1 is 0.25, and the flat-top shed 1 is provided with a flat top and an umbrella Skirt, the diameter of flat top is 8.5cm, and the diameter of umbrella skirt is 14.5cm, and the height of umbrella skirt is 7.6cm; A wire groove 4 is set in the middle of the flat top surface of flat top umbrella skirt 1, and 3 wire grooves are arranged in wire groove 4. An arc-shaped wire groove horizontal shallow groove 41, a circular fixed card jack 9 is res...

Embodiment 2

[0035] The needle-type transparent insulator is provided with a flat-top shed skirt 1, a flat-top shed skirt central tube 2, a pressure plate 3, a connecting handle 6, a metal sleeve 7, and supporting bolts 8. The above-mentioned pressure plate 3, flat-top shed skirt 1, Flat-top umbrella skirt central tube 2, connecting handle 6, metal sleeve 7, support bolt 8 are connected in sequence.

[0036] Further, the pressure plate 3, the flat-top shed 1 and the flat-top shed central tube 2 are made of polycarbonate, the thickness of the flat-top shed 1 is 0.35cm, and the flat-top shed 1 is provided with a flat top and a The umbrella skirt, the diameter of the flat top is 9.5cm, the diameter of the umbrella skirt is 19cm, and the height of the umbrella skirt is 9cm; a wire groove 4 is arranged in the middle of the flat top surface of the flat top umbrella skirt 1, and 4 wire grooves are arranged on the wire groove 4 Arc-shaped wire groove horizontal shallow groove 41, two square fixed ...

Embodiment 3

[0043] The pin-type transparent insulator is provided with a pressure plate 3, a flat-top shed 1, a flat-top shed central tube 2, a connecting handle 6, a metal sleeve 7, and a support bolt 8. The pressure plate 3, the flat-top shed 1, The flat-top umbrella skirt central tube 2, the connecting handle 6, the metal sleeve 7, and the supporting bolt 8 are connected in sequence.

[0044] Further, the pressure plate 3, the flat-top shed 1 and the flat-top shed center tube 2 are made of polycarbonate, the thickness of the flat-top shed 1 is 0.5 cm, and the flat-top shed 1 is provided with a flat top and a flat top. Umbrella skirt, the diameter of the flat top is 2.4cm, the diameter of the umbrella skirt is 4.8cm, and the height of the umbrella skirt is 2.55cm; Two arc-shaped wire grooves are horizontally shallow grooves 41, and a square fixing card socket 9 is respectively provided on the flat tops of the flat-top shed 1 on the left and right sides of the wire groove 4, and the inne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com