Multi-clamp tool for piston connecting rod and operation method thereof

A technology of piston connecting rod and multiple fixtures, which is applied in the direction of clamping, positioning devices, manufacturing tools, etc., can solve the problems of low production efficiency and achieve the effect of improving production efficiency and reducing distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

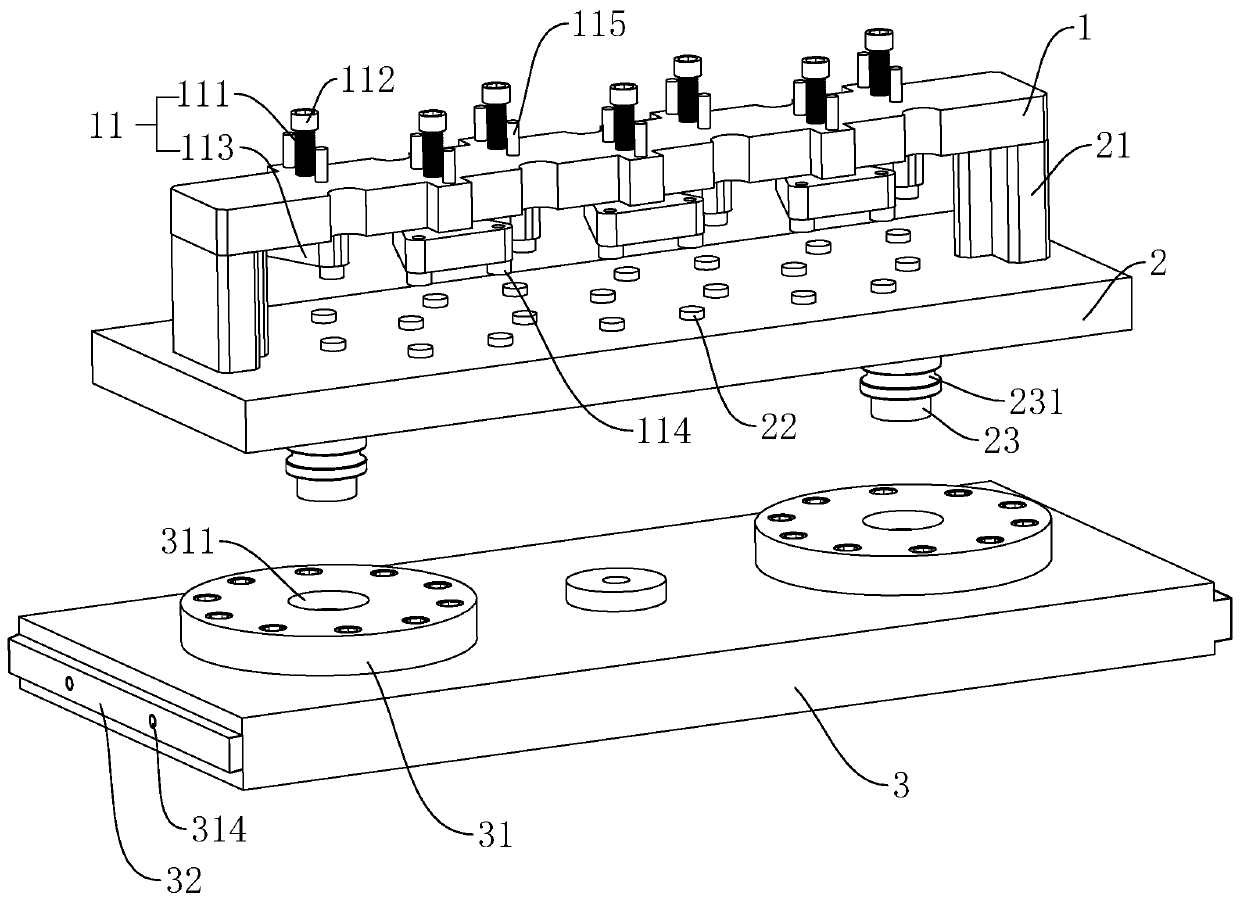

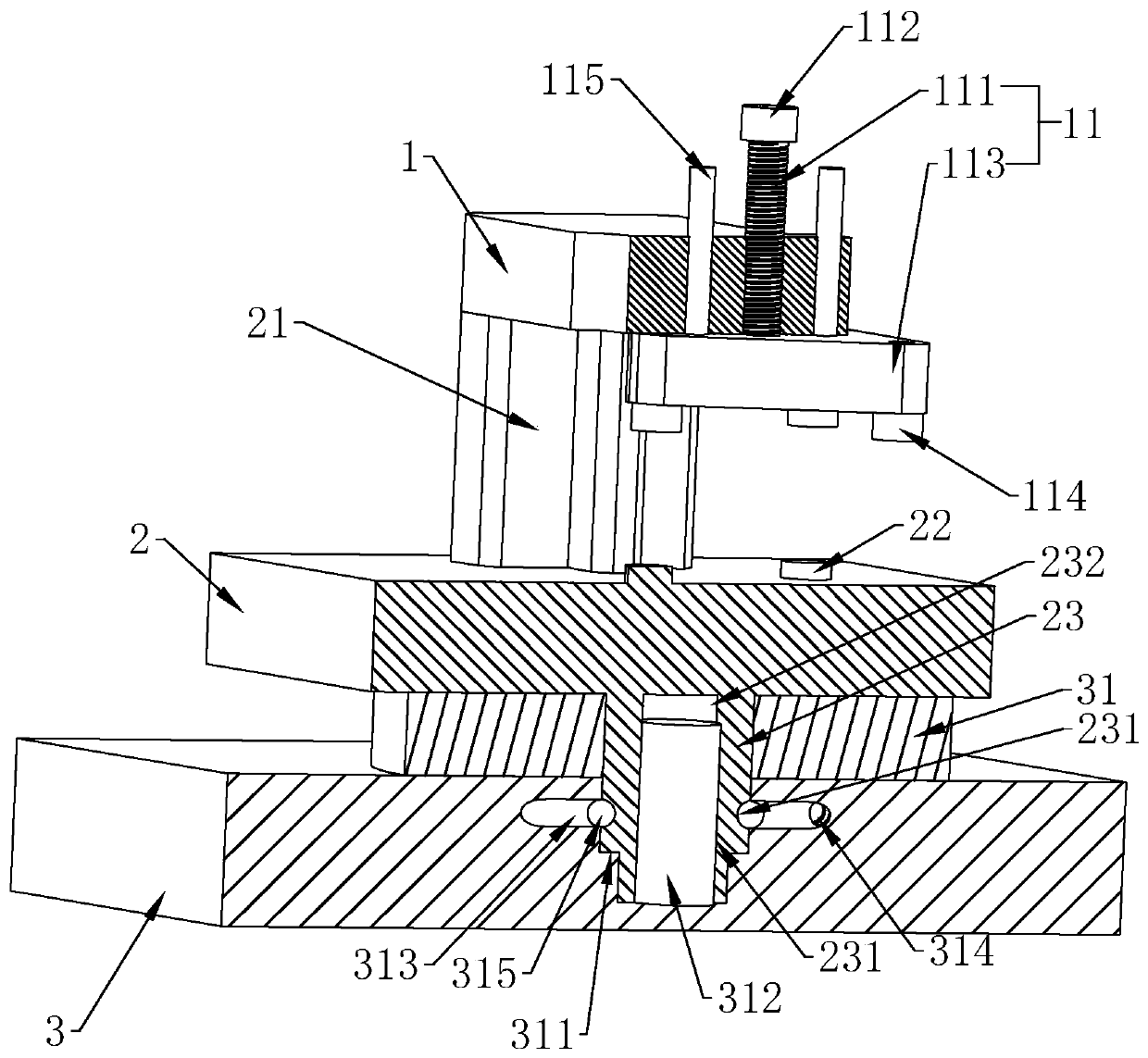

[0045] refer to figure 1 and image 3, is a multi-clamp tooling for piston connecting rods disclosed in the present invention, including a bottom plate 2, a cover plate 1 and a fixing seat 3 for connecting with a workbench of a numerical control machining center. The base plate 2 is detachably connected with the fixing seat 3, the top of the base plate 2 is provided with support columns 21 along the vertical direction at both ends of its length direction, the cover plate 1 is located directly above the base plate 2 and its two ends in the length direction are connected to two supports. Columns 21 are detachably connected by bolts. The cover plate 1 is provided with a plurality of clamps 11 for fixing the piston connecting rod 4 along its length direction, so that multiple piston connecting rods 4 can be fixed on the base plate 2 at the same time, and then the base plate 2 is fixed on the numerical control through the fixing seat 3 On the working table of the machining center...

Embodiment 2

[0051] refer to figure 1 and figure 2 , a method of operating a multi-clamp tooling for a piston connecting rod applied in Embodiment 1, comprising the following steps:

[0052] S1: Fixing seat 3 is installed on the workbench of numerical control machining center;

[0053] That is, the card is embedded on the workbench of the numerical control machining center through the slide blocks 32 at both ends of the fixing seat 3. The workbench of the numerical control machining center is provided with two columns, and the opposite sides of the two columns are provided with chute, and the fixing seat 3 cards are embedded in the chute, and now the air outlet of the workbench in the chute is aligned with the air inlet of the air passage 314 at both ends of the holder 3.

[0054] S2: rotate the screw rod 111 by rotating the handle 112 to make the triangular pressing plate 113 rise in the vertical direction;

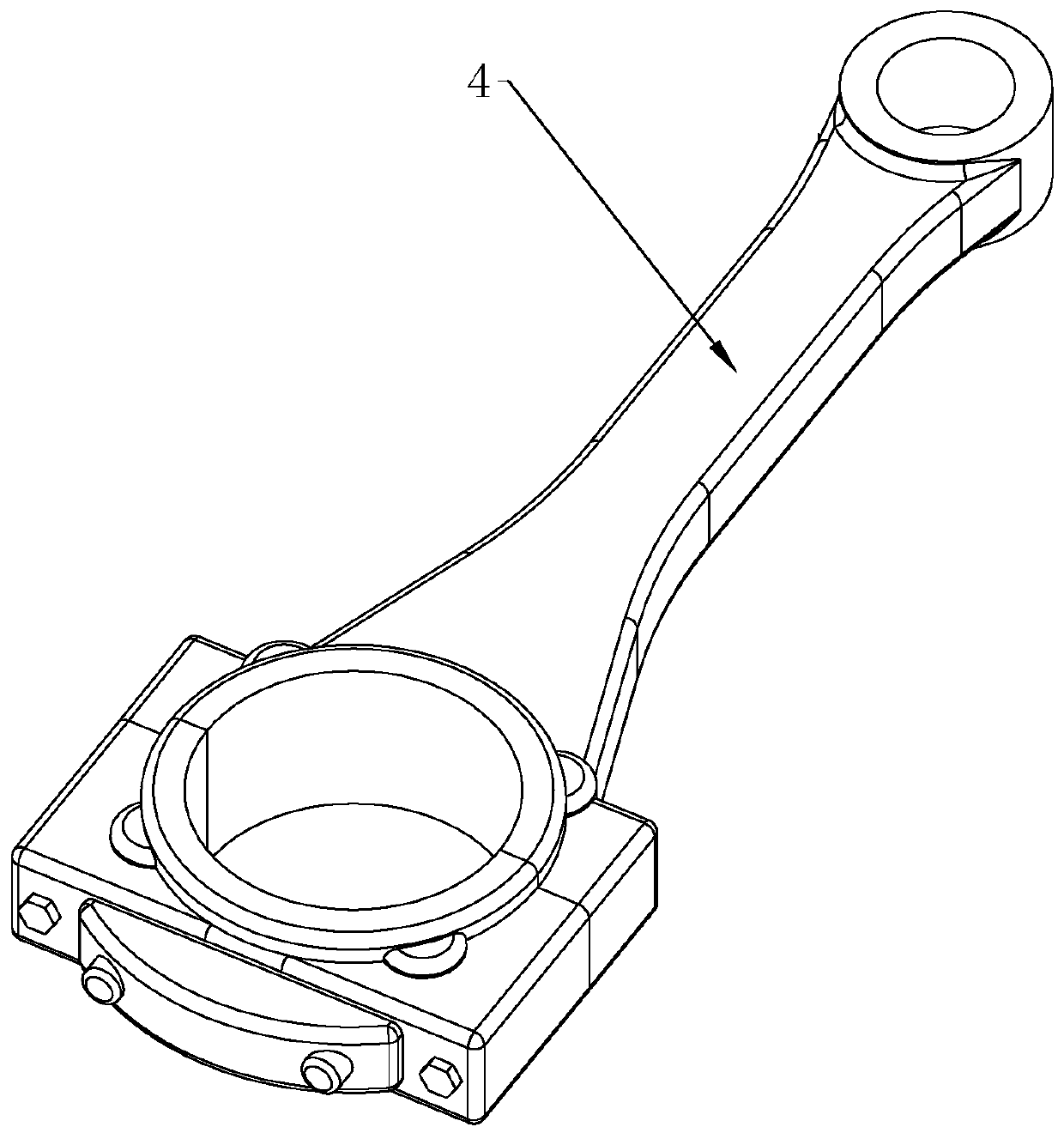

[0055] S3: The piston connecting rod 4 that will need to be processed (refer...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap