Clamping device of manual assembly table of digital production line

A production line and artificial technology, applied to workbenches, manufacturing tools, hand-held tools, etc., can solve the problems of reducing production efficiency, increasing production costs, reducing machine tool utilization, etc., and achieve the effect of solving machine time occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below with reference to the accompanying drawings and examples.

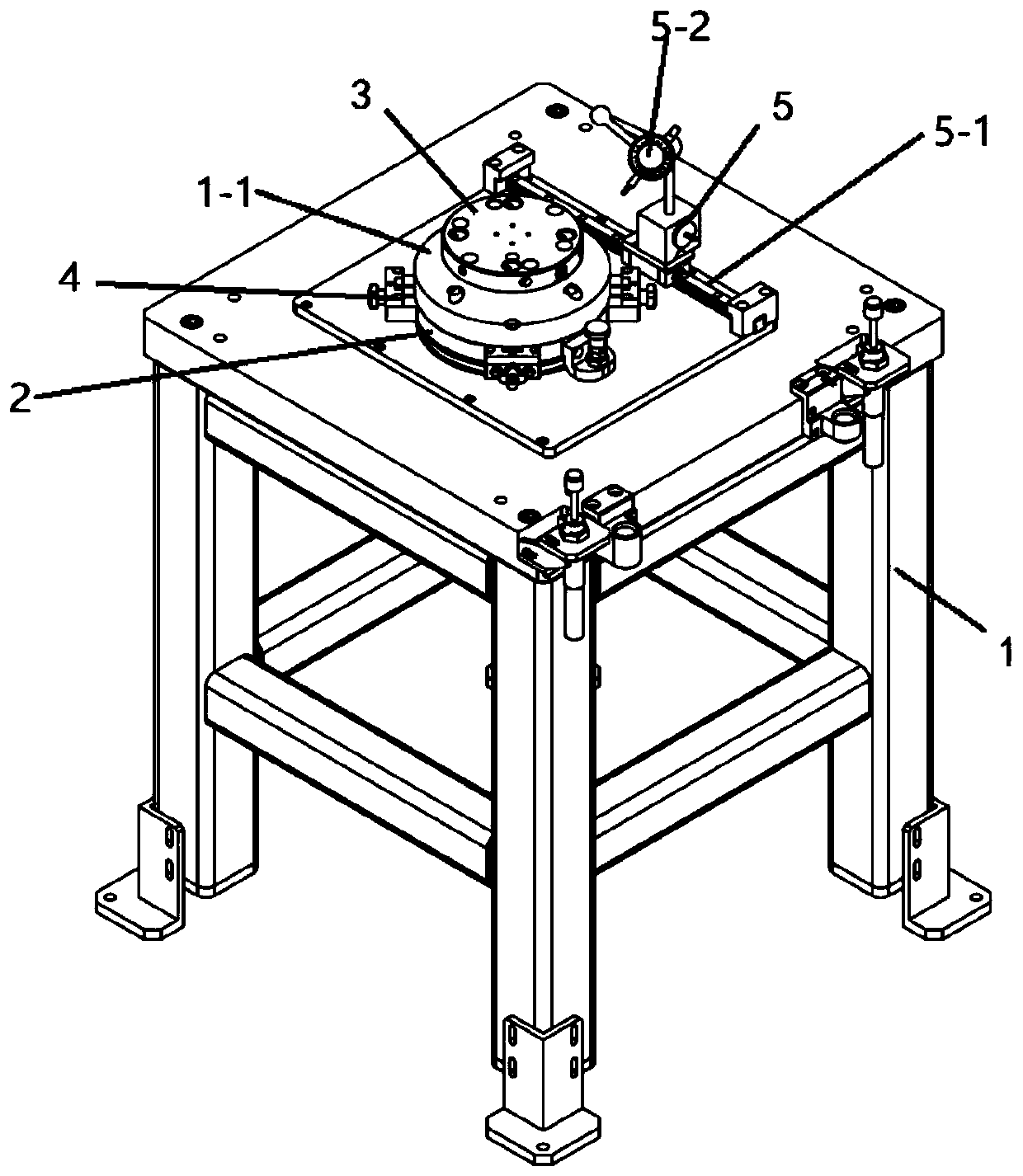

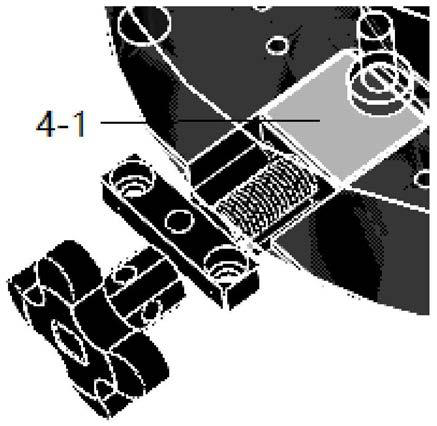

[0019] Aiming at the inefficiency caused by conventional online clamping and alignment, the present invention proposes a digital production line manual assembly table clamping device, including a basic platform 1, a rotary platform 2, a zero-point quick change mechanism 3, an accuracy adjustment mechanism 4 and a detection Institutions 5, such as figure 1 As shown, the rotary platform 2 and the detection mechanism 5 are installed on the basic platform 1 , and the zero-point quick change mechanism 3 and the precision adjustment mechanism 4 are installed on the rotary platform 2 . The product to be found is installed on the zero-point quick-change mechanism 3 .

[0020] Among them, the basic platform 1 is made of cast iron and fastened with feet to ensure the stability of the entire assembly platform;

[0021] The rotary platform 2 uses high-precision ball...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap