Aerated brick blank shelling circulating device

A technology of circulation device and aerated brick, which is applied in the direction of unloading device, auxiliary molding equipment, ceramic molding machine, etc., can solve the problems of low production efficiency and long production cycle of the production process of aerated brick, so as to improve production efficiency, The effect of reducing the running interval time and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings.

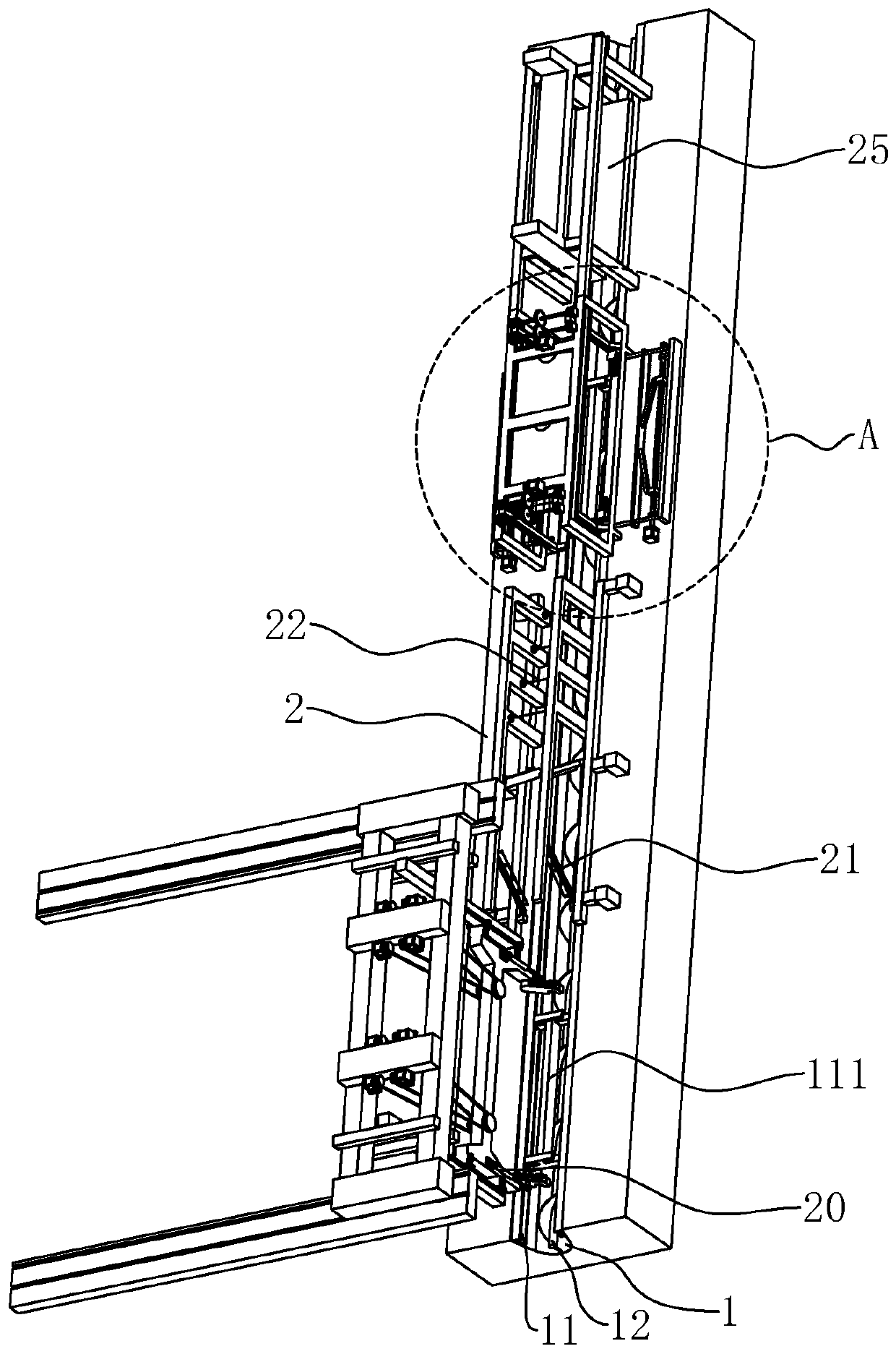

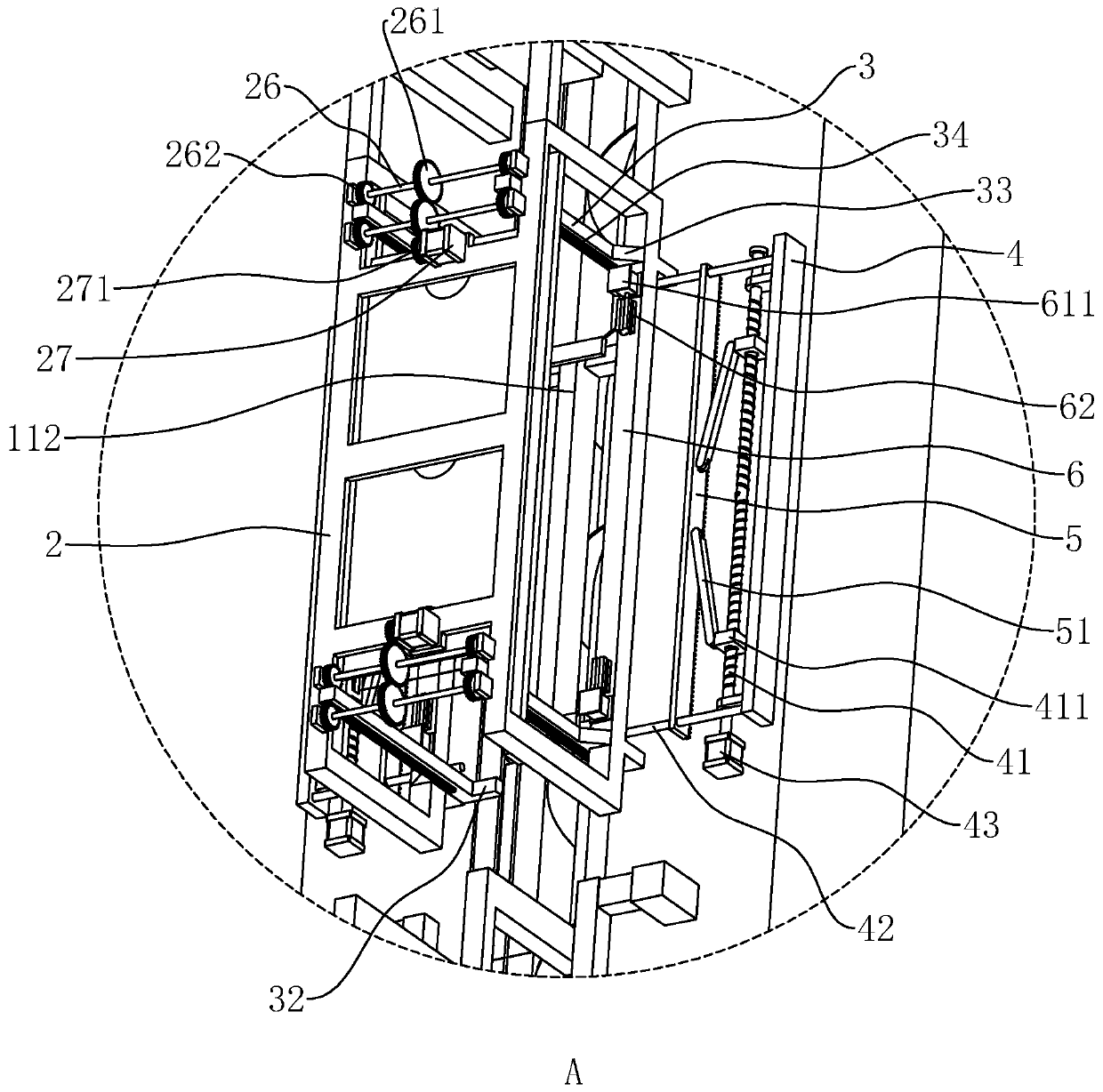

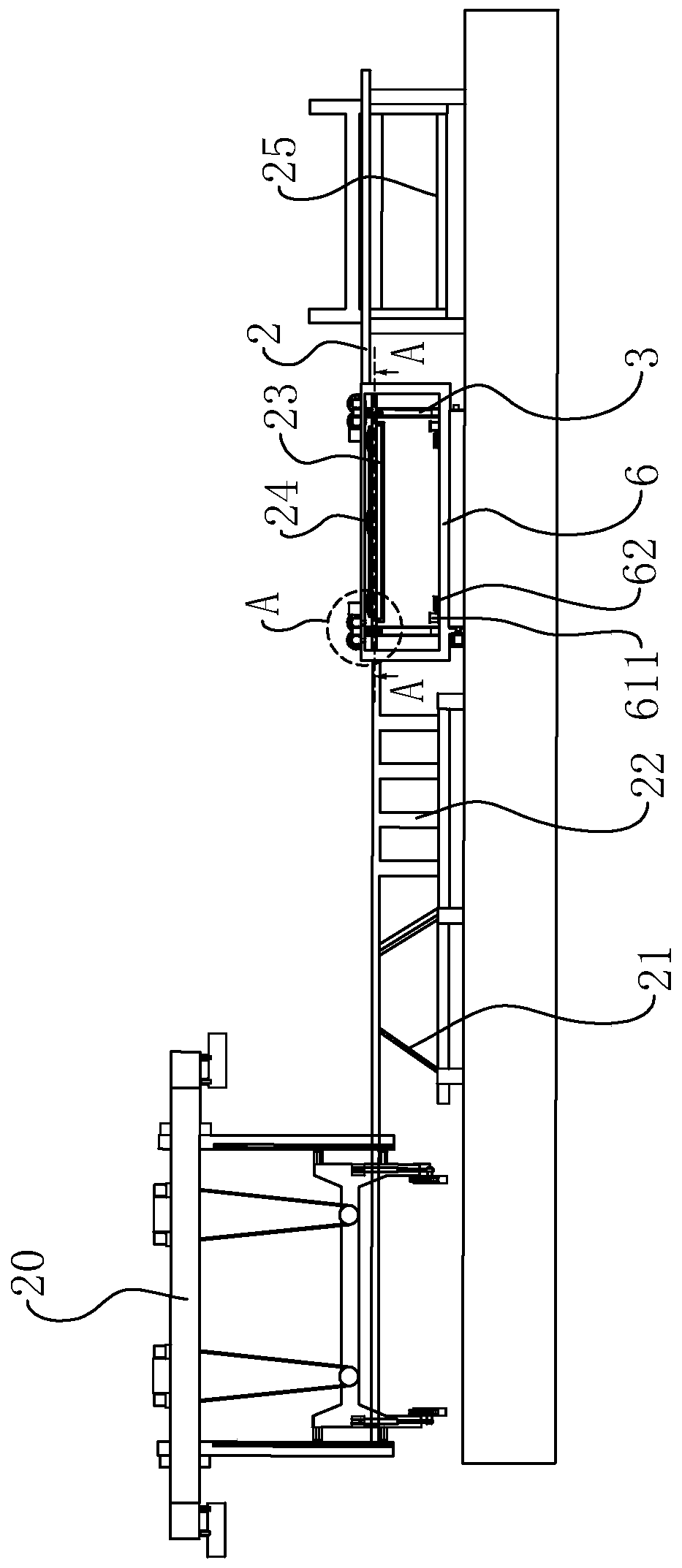

[0038] refer to figure 1 and figure 2 , is a kind of aerated brick body peeling circulation device disclosed in the present invention, including a waste material chute 1, conveying guide rails 11 set on both side walls of the waste material trough 1, and a first mobile trolley 111 and a second moving trolley walking on the conveying guide rail 11. Mobile dolly 112. Frame 2 is positioned at the top of conveying guide rail 11, and frame 2 is provided with demoulding station, cutting station and overturning station successively along the length direction of conveying guide rail 11, and the first moving trolley 111 is in demoulding station and cutting station The green body to be cut is transported between the second mobile trolley 112, and the finished green body is transported between the cutting station and the turning station. Air brick production efficie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com