Hot mixing machine for plastic processing

A hot mixer and plastic technology, applied in the field of plastic processing, can solve the problems of affecting discharge, raw material cooling and solidification, bonding, etc., and achieve the effect of preventing clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

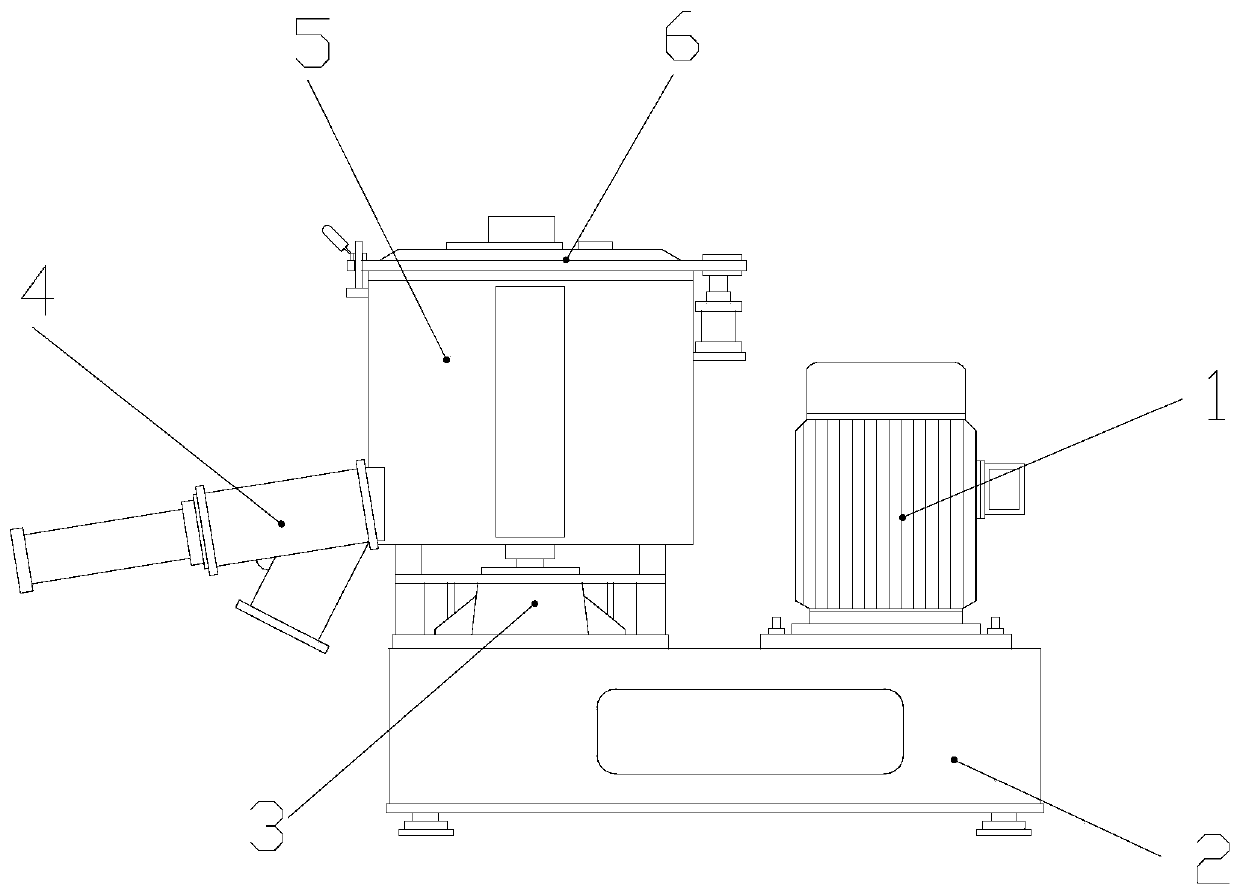

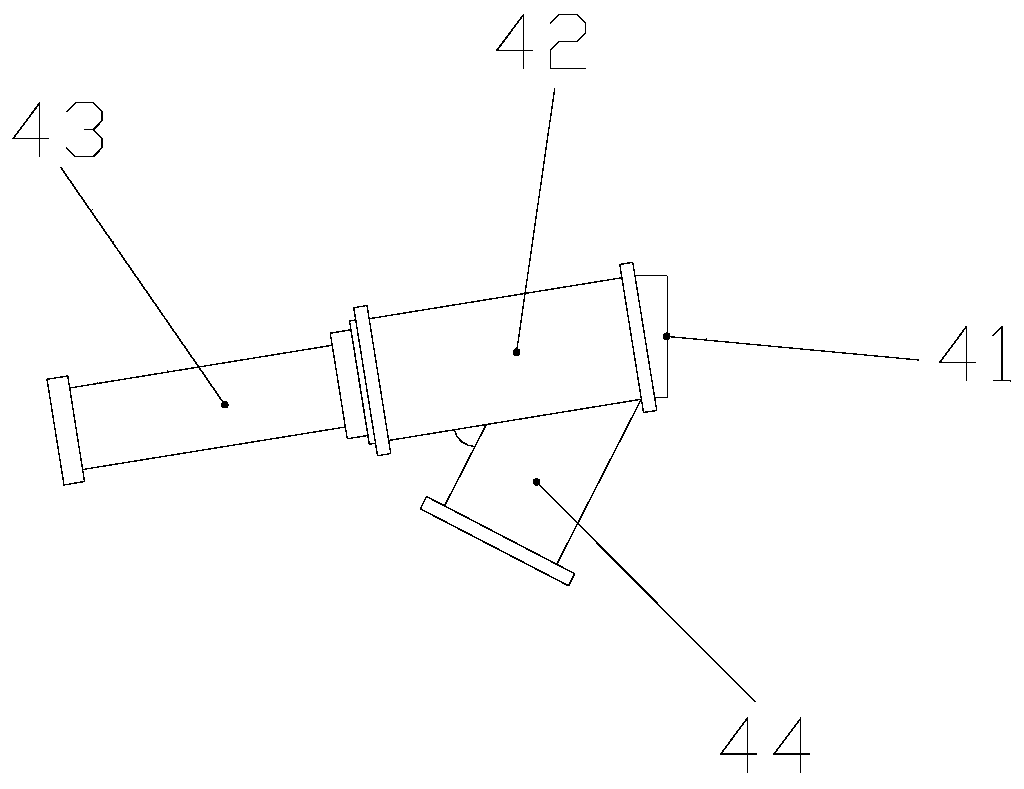

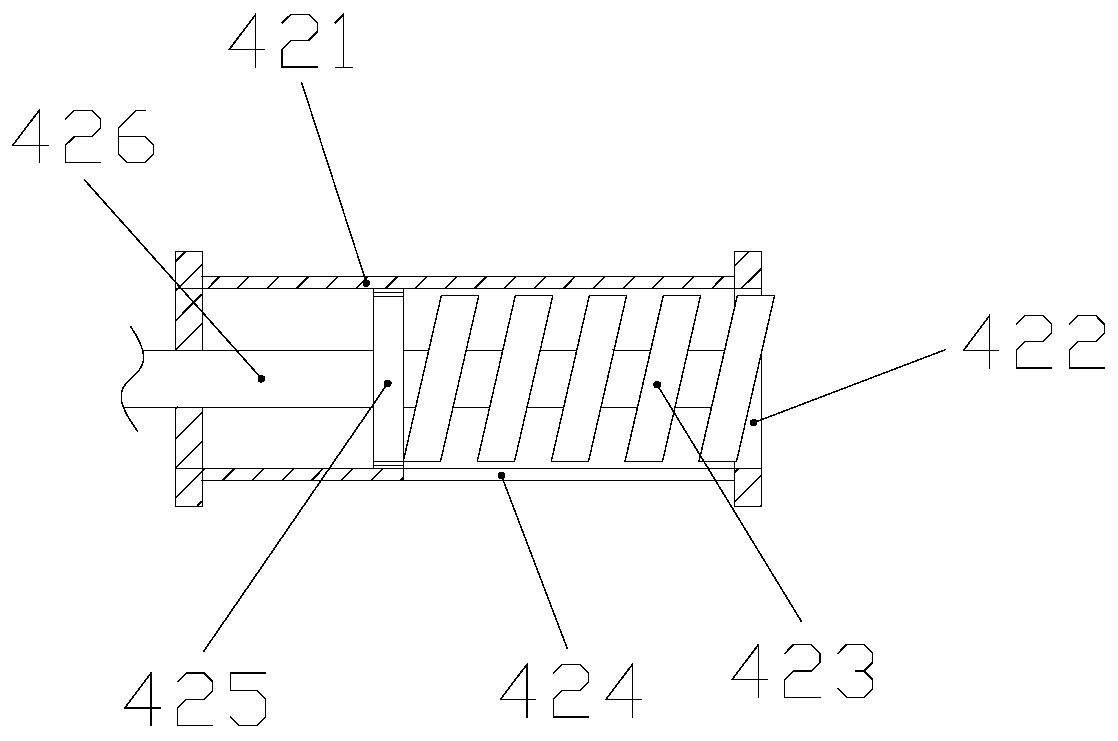

[0027] Example 1: Please refer to Figure 1-Figure 5 , the specific embodiments of the present invention are as follows:

[0028] Its structure includes a motor 1, a transmission case 2, a drive seat 3, a discharge structure 4, a heat mixing tank 5, and an upper cover 6. The motor 1 is vertically installed on the upper end of the transmission case 2 and is mechanically connected. The drive seat 3 Installed on the right side of the upper end of the transmission case 2 and meshed inside, the hot mixing tank 5 is vertically installed on the upper end of the driving base 3 and located on the same axis, the upper cover 6 is arranged on the upper end of the hot mixing tank 5 and is mechanically connected, The discharge structure 4 is embedded and installed at the lower left end of the heat mixing tank 5 and connected inside; the discharge structure 4 includes a discharge port 41, a conduction structure 42, a drive motor 43, and a discharge pipe 44. The port 41 is located on the rig...

Embodiment 2

[0036] Example 2: Please refer to Figure 1-Figure 7 , the specific embodiments of the present invention are as follows:

[0037]Its structure includes a motor 1, a transmission case 2, a drive seat 3, a discharge structure 4, a heat mixing tank 5, and an upper cover 6. The motor 1 is vertically installed on the upper end of the transmission case 2 and is mechanically connected. The drive seat 3 Installed on the right side of the upper end of the transmission case 2 and meshed inside, the hot mixing tank 5 is vertically installed on the upper end of the driving base 3 and located on the same axis, the upper cover 6 is arranged on the upper end of the hot mixing tank 5 and is mechanically connected, The discharge structure 4 is embedded and installed at the lower left end of the heat mixing tank 5 and connected inside; the discharge structure 4 includes a discharge port 41, a conduction structure 42, a drive motor 43, and a discharge pipe 44. The port 41 is located on the righ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com