Heat dissipation mechanism for gear grinding machine

A technology of heat dissipation mechanism and grinding machine, which is applied to the parts of grinding machine tools, cleaning methods using tools, grinding machines, etc. It can solve the problems of affecting the efficiency of grinding, requiring high precision of tooth surfaces, and burning out grinding devices, etc., to achieve Improve grinding efficiency, reduce grinding cost and improve grinding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

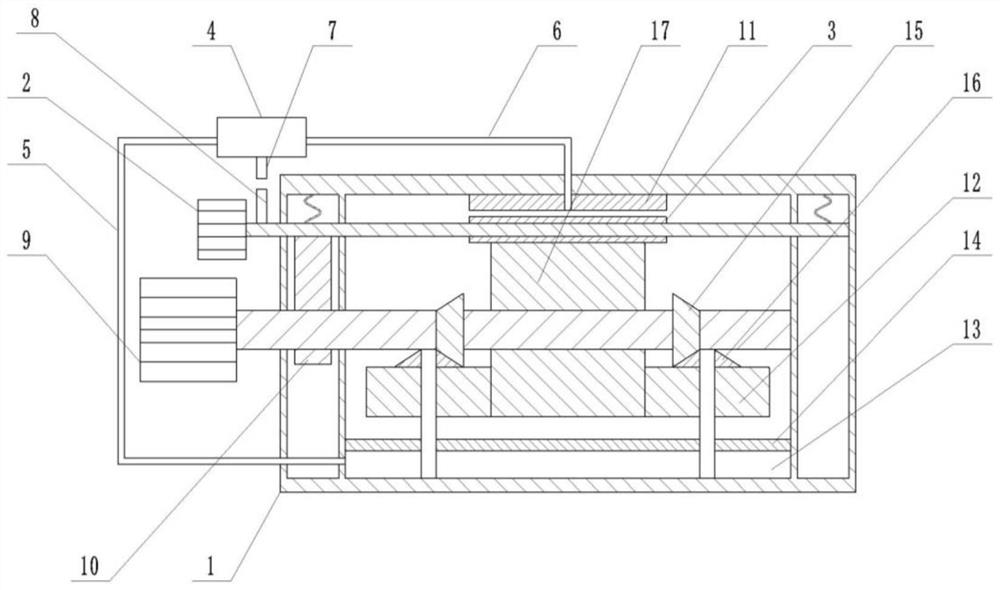

[0029] Embodiment 1 is basically as attached Figure 1-2 Shown:

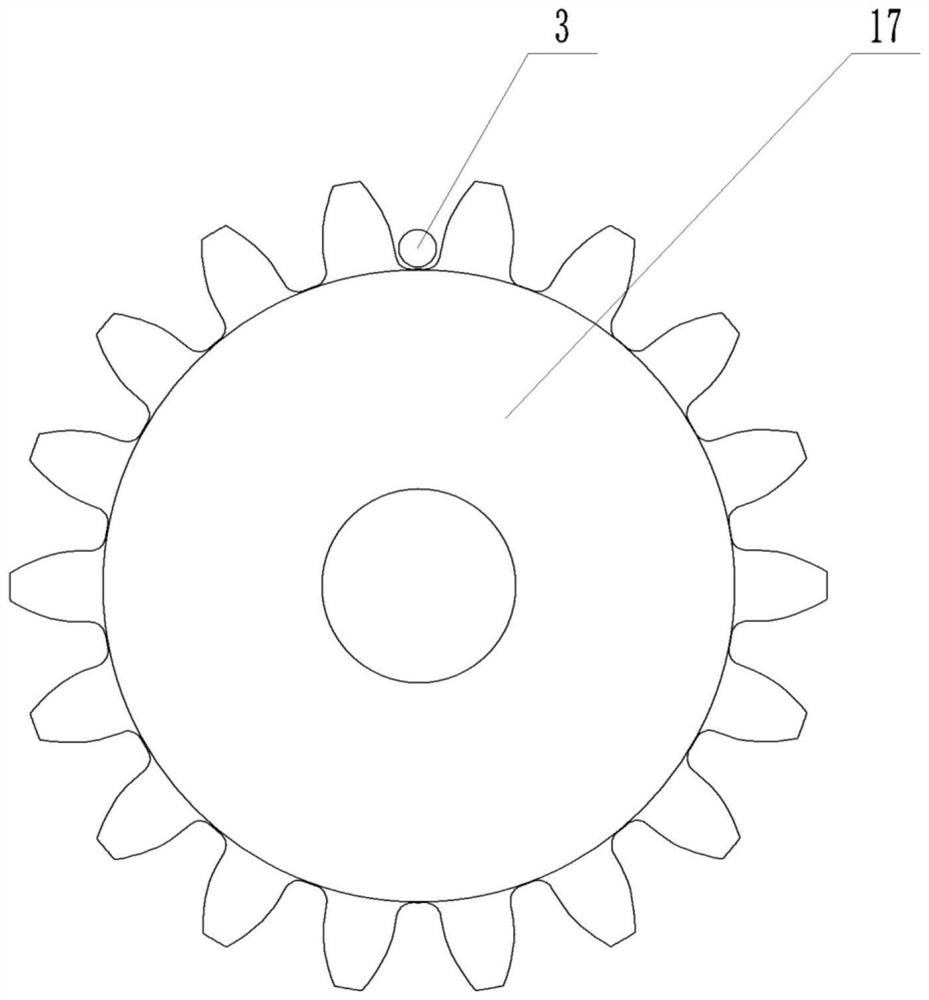

[0030] A heat dissipation mechanism of a gear 17 grinding machine comprises a frame 1, a grinding device and a heat dissipation device, and the grinding device is arranged on the frame 1.

[0031] The grinding device comprises a first rotating motor 2 and a teeth grinding roller 3, the first rotating motor 2 is fixedly arranged on the frame 1, and the output shaft two ends of the first rotating motor 2 are rotatably arranged on the frame 1, and the teeth grinding roller 3 is fixed on the output shaft, the diameter of the tooth grinding roller 3 is larger than that of the output shaft, the tooth grinding roller 3 is coaxially arranged with the output shaft, and the diameter of the tooth grinding roller 3 matches the tooth root of the gear 17;

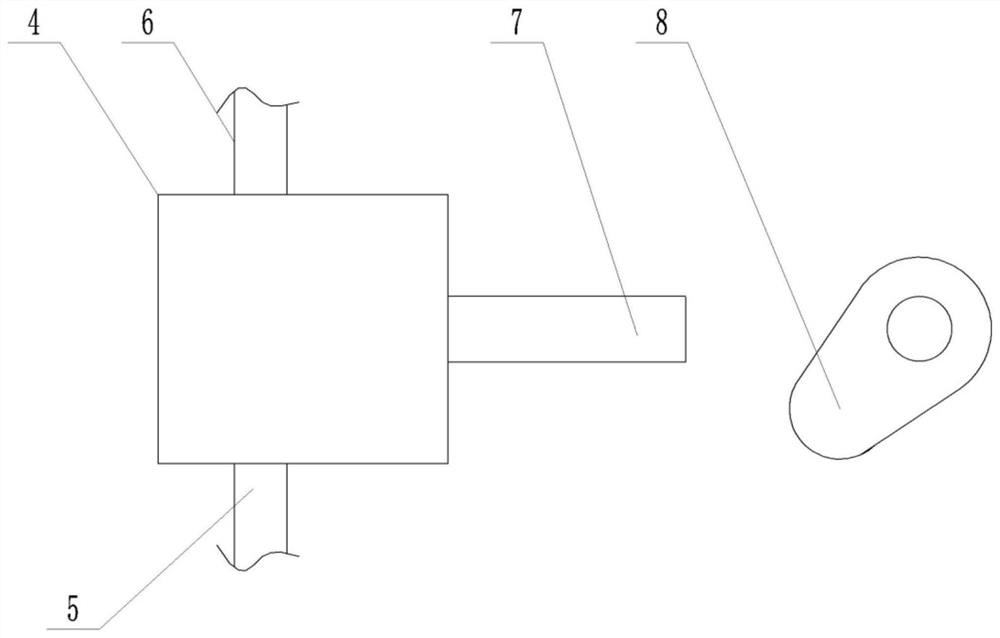

[0032] as attached Figure 3-4 Shown:

[0033] The cooling device includes a water cylinder 4, a water inlet pipe 5 and a water outlet pipe 6. The water cylinder 4 slid...

Embodiment 2

[0045] The difference between this embodiment 2 and embodiment 1 is that, as attached Figure 5 Shown:

[0046] It also includes a storage mechanism. The storage mechanism includes a storage rack 18 and a moisture monitoring assembly. The storage rack 18 is sequentially provided with a storage frame 19 for storing gear workpieces from top to bottom.

[0047] Moisture monitoring assembly is located at the top of storage rack 18, and moisture monitoring assembly includes casing 20, oil pot 21, water absorption drying box 22, load-bearing plate 23, pressure sensor 26 and single-chip microcomputer, and oil pot 21 and load-bearing plate 23 are all arranged on casing 20 Above, the water-absorbing drying box 22 is slidingly arranged on the box body 20, and the water-absorbing drying box 22 and the bearing plate 23 are connected by a spring. Matching pressure switch 25, the pressure switch 25 is used to control the energization of the pressure sensor 26, the pressure sensor 26 is arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com