Leveller bar for coking ovens

A coking oven and flat coal technology, applied in the field of flat coal rods, can solve problems such as uncontrollable emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

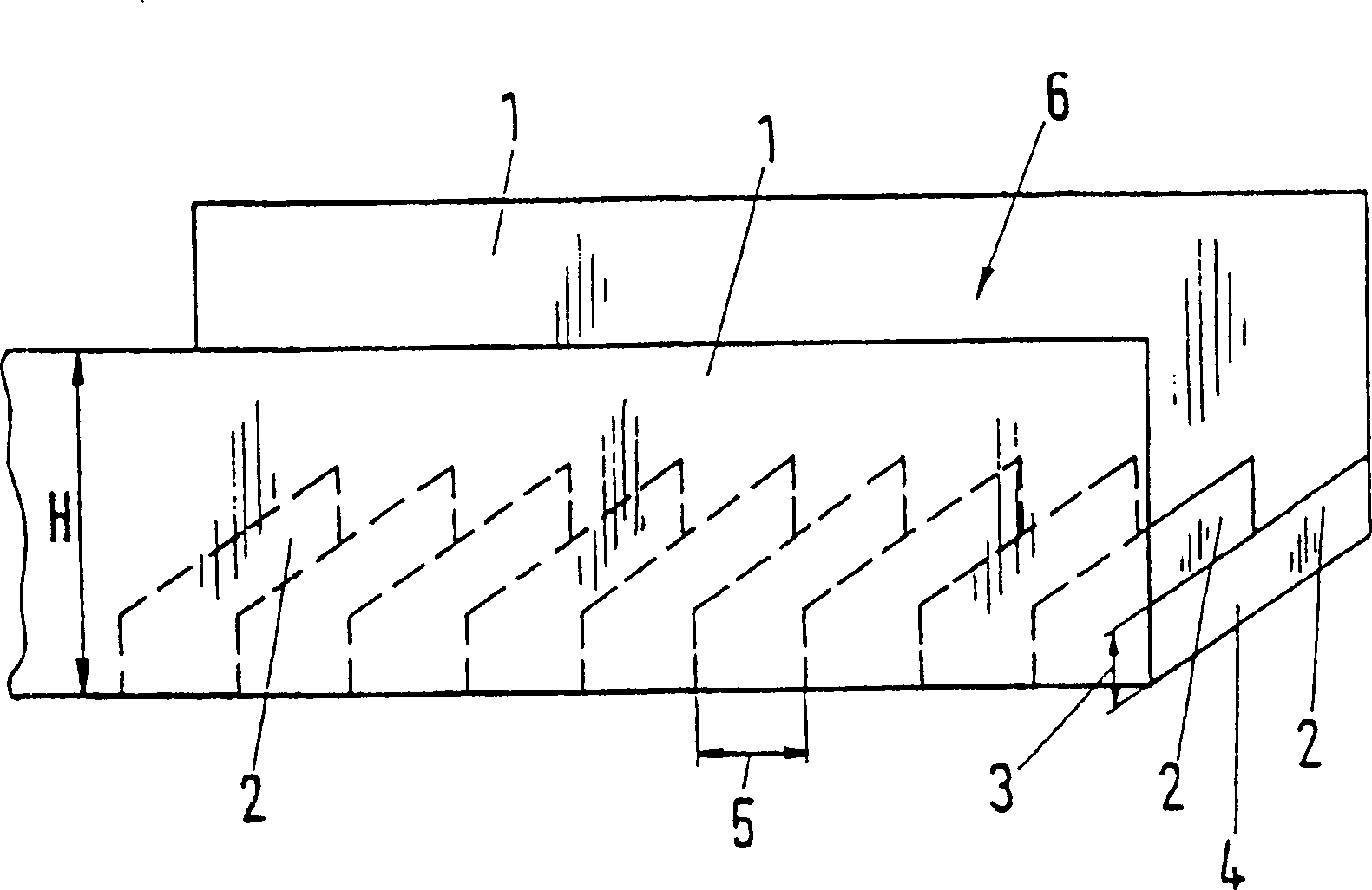

[0045] exist figure 1 shows a flat coal rod with jaws 1 and a scraper 2 between the jaws 1 . The height 3 of the flat coal plate 2 is significantly smaller than the height H of the jaw plate 1 . The flat coal plate (2) is arranged front and back by a certain distance 5, and its transverse web area 4 has only blocked a small part of the middle area between the jaw plates 1, so an unimpeded gas passage 6 has been formed.

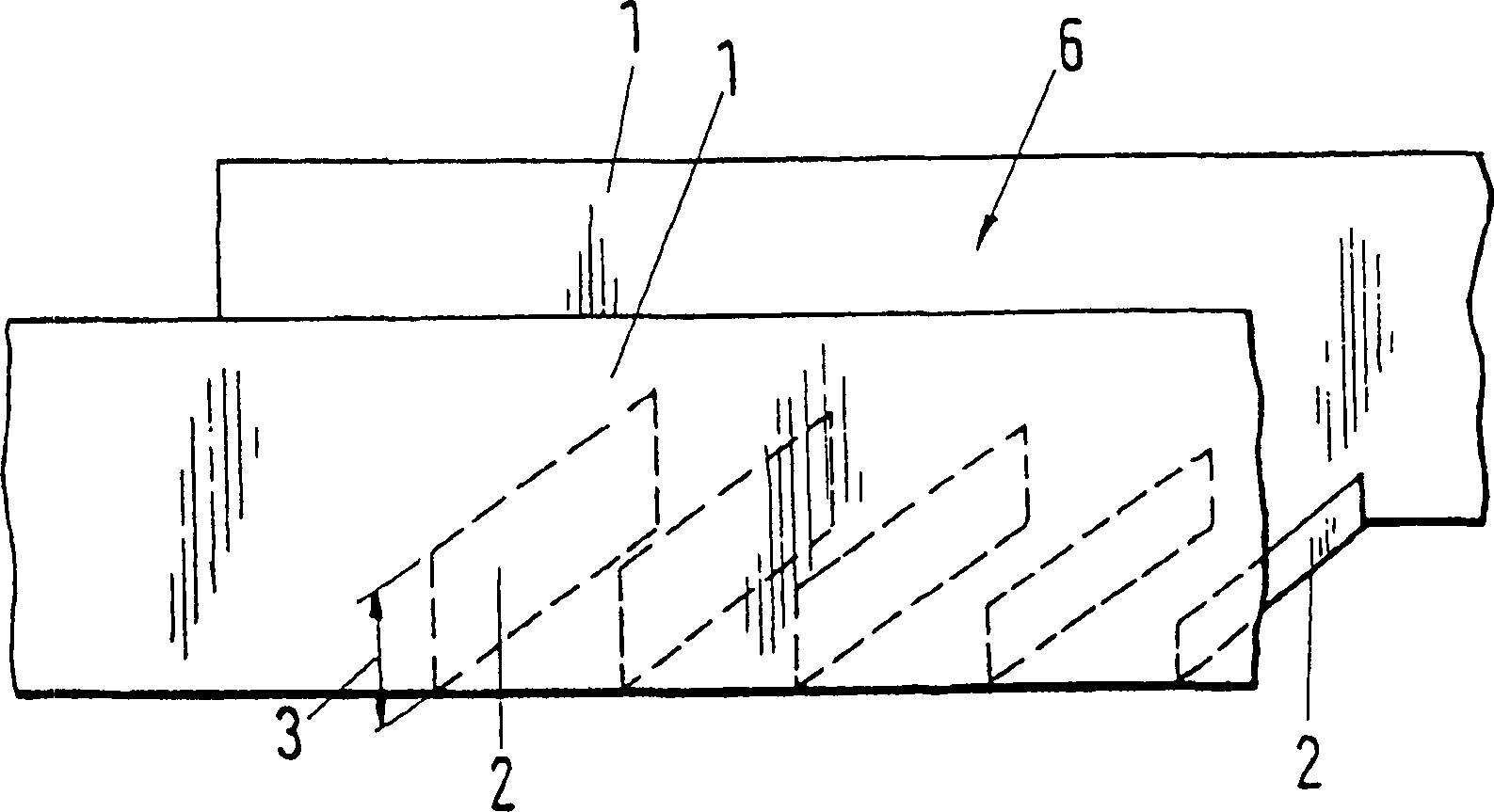

[0046] From figure 2 It can be seen that a number of flat coal plates 2 are arranged one behind the other between the jaw plates 1 , and they have different heights 3 . The advantage of this type of structure is that several low flat coal slabs 2 cannot pile up coal mountains in front of themselves. Spilled coal can be dropped into the next grid and carried away from there. There is an unimpeded gas channel 6 at any time above the flat coal plate 2.

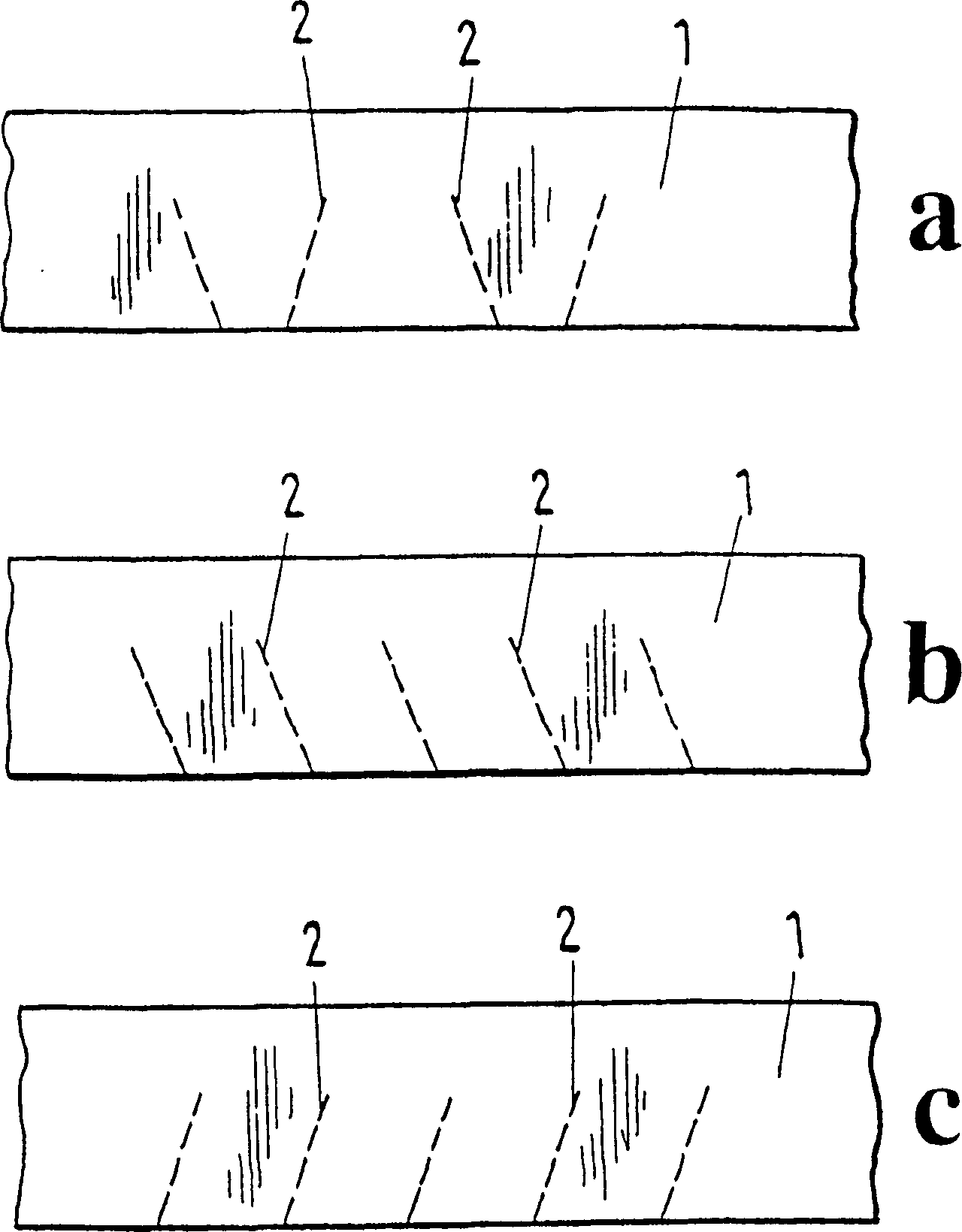

[0047] image 3 It represents, for example, a flat coal plate 2 fixed on the jaw plate 1 at a certain i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com