Device for treating cremation waste gas of cremation furnace

A waste gas treatment device and furnace fire technology, applied in the direction of incinerators, methods of incinerating corpses, chemical instruments and methods, etc., can solve problems such as air pollution, filter blockage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

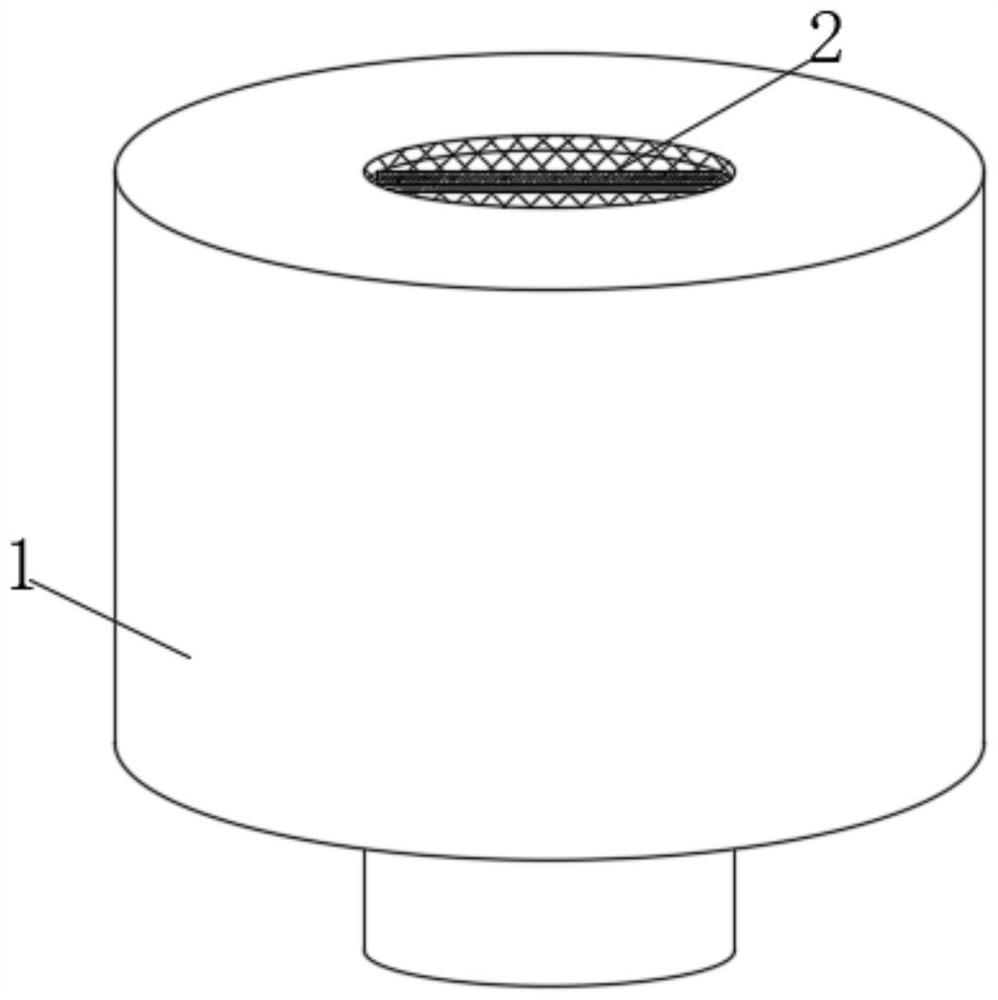

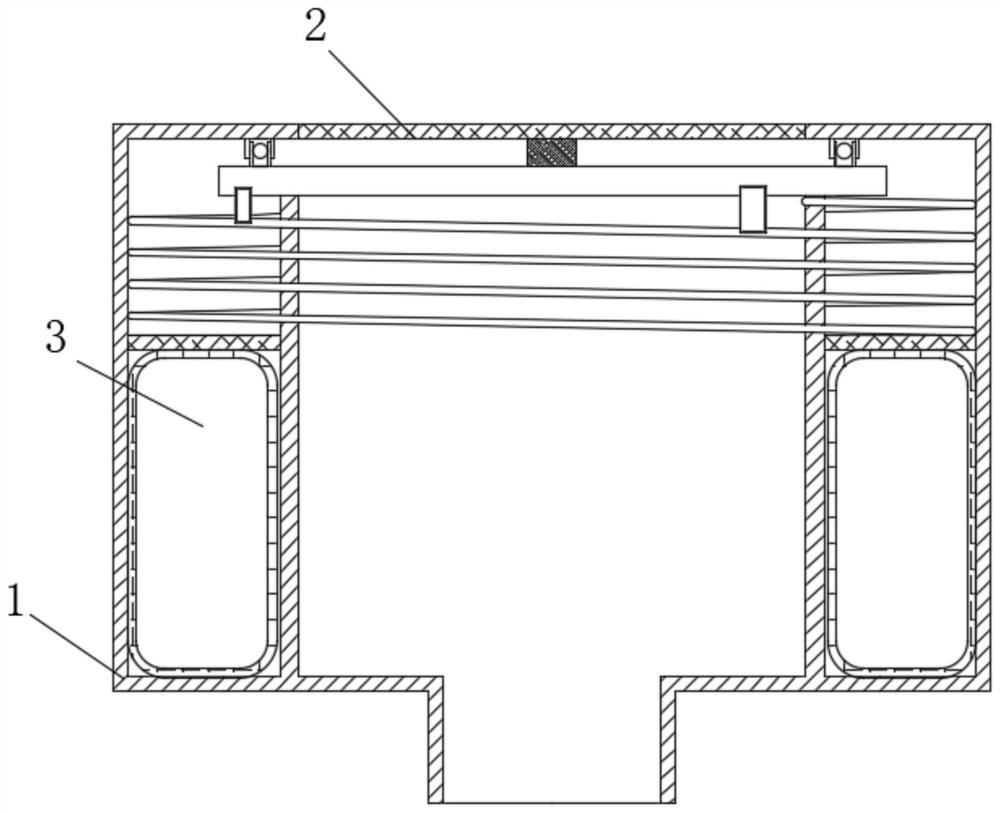

[0021] Such as Figure 1-7 As shown, the present invention provides a technical solution: a cremation furnace cremation waste gas treatment device, including a cylinder 1, an opening is opened on the upper side of the cylinder 1, a filter screen 2 is arranged in the opening, and the edge of the filter screen 2 is in contact with the cylinder The body 1 is fixedly connected, and the interior of the cylinder body 1 is provided with a cleaning mechanism 3;

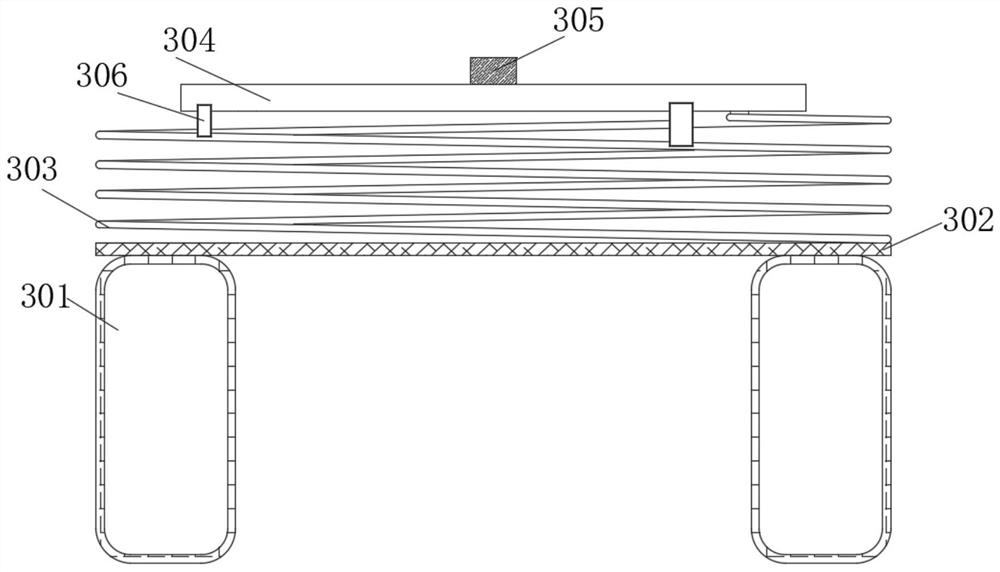

[0022] The cleaning mechanism 3 includes an air bag 301, a stabilizing ring 302, a screw rod 303, a fixed ring 304, a hair brush 305, a fixed block 306, a sliding mechanism 307, a fixed plate 308, and a dust scraping mechanism 309. The lower surface of the air bag 301 is fixedly connected to the cylinder. The bottom of the outer inner wall of the body 1, the upper surface of the airbag 301 is fixedly connected with the lower surface of the stabilizing ring 302, the upper surface of the stabilizing ring 302 is fixedly connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com