Anti-bulging tire

A technology for tires and bulges, which is applied to tire parts, reinforcing layers of pneumatic tires, sidewalls of tires, etc., can solve problems such as airtight layer damage, air leakage, damage, etc., to reduce damage, reduce bulge damage, and reduce shrinkage Effect of Ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

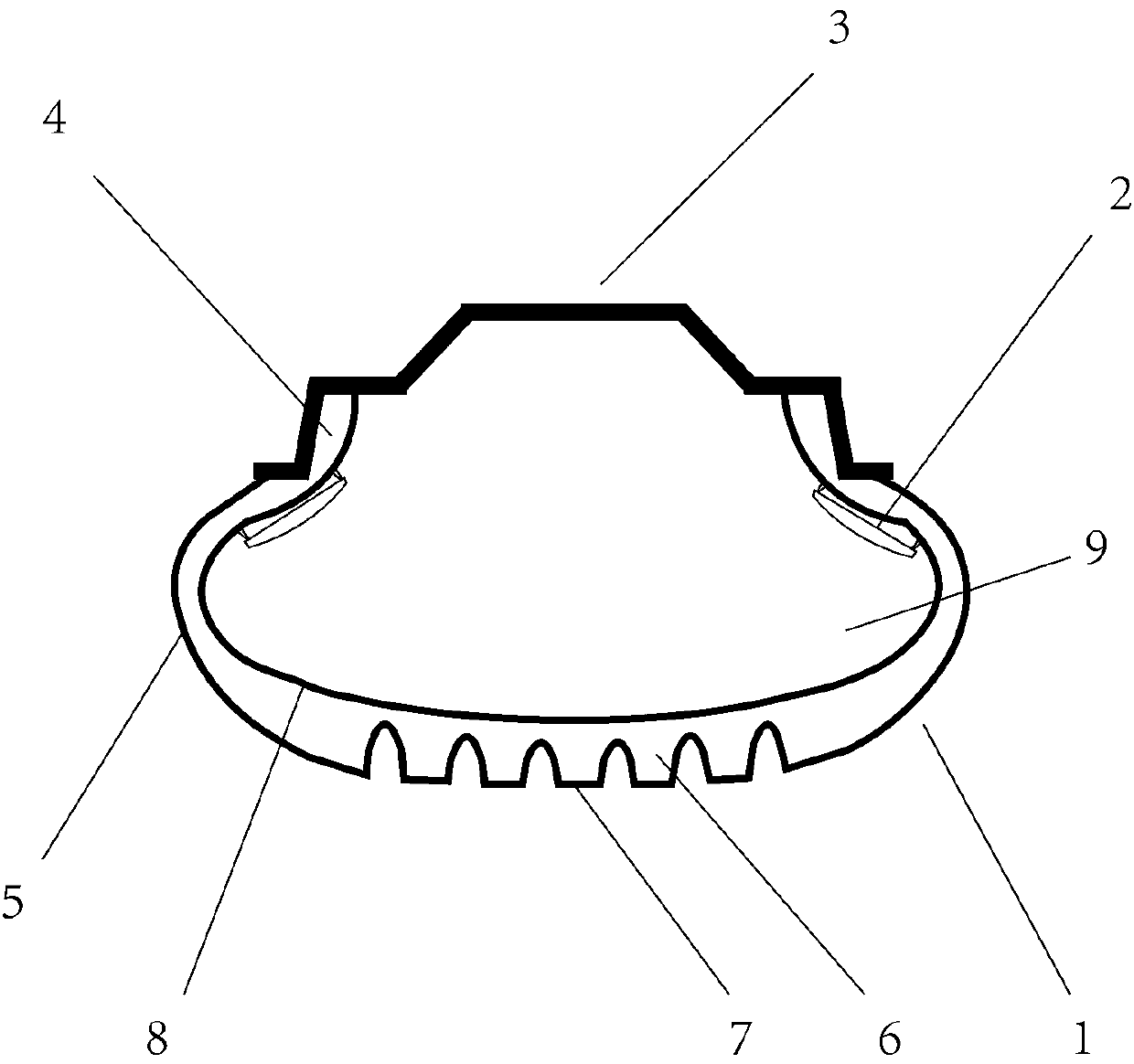

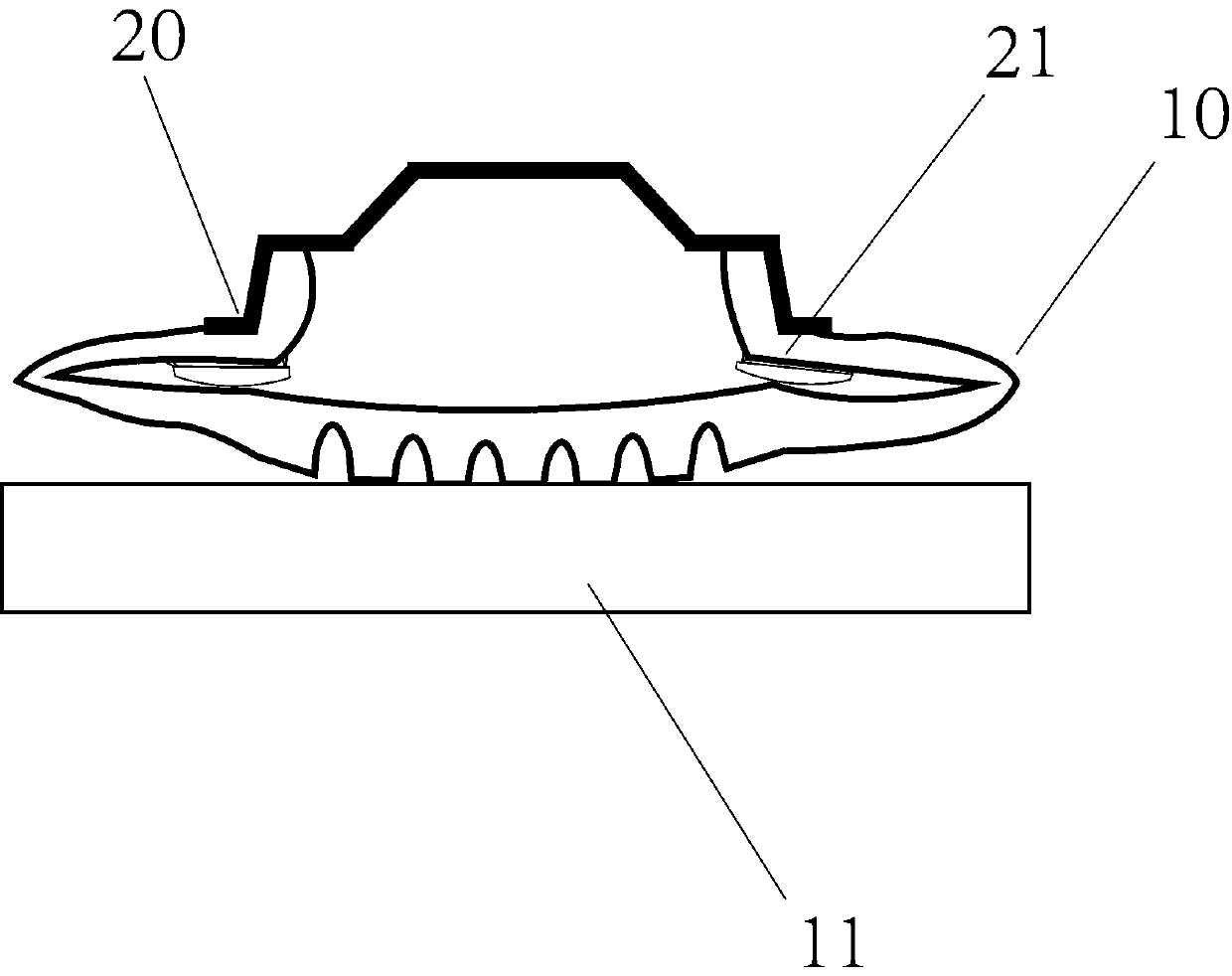

[0031] Embodiment 1: An anti-bulge tire, including a tire 1 and a force-guiding structure 2. The force-guiding structure 2 is located inside the tire 1 and connected to the inner wall 8 of the tire. The force-guiding structure 2 includes a rubber strip 16 and a connecting foot 17. The rubber strip 16 is set at the lower tangent point 21 of the rim edge of the tire 1, connected with the inner wall 8 through the connecting foot 17, and circles the inner wall 8. A tire 1 is provided with at least two force-conducting structures 2, which are located at two rim edges of the tire 1. On the inner wall at the lower tangent point 21, the rubber strip 16 has a thickness of 10mm, and the rubber strip 16 is provided with two joints 18, and each joint 18 is connected to one connecting foot 17, as Figure 7 As shown, the connecting pin 17 is provided with a ventilation window 19, such as Figure 5 One end of the connecting foot 17 shown is connected to the rubber strip 16, and the other end...

Embodiment 2

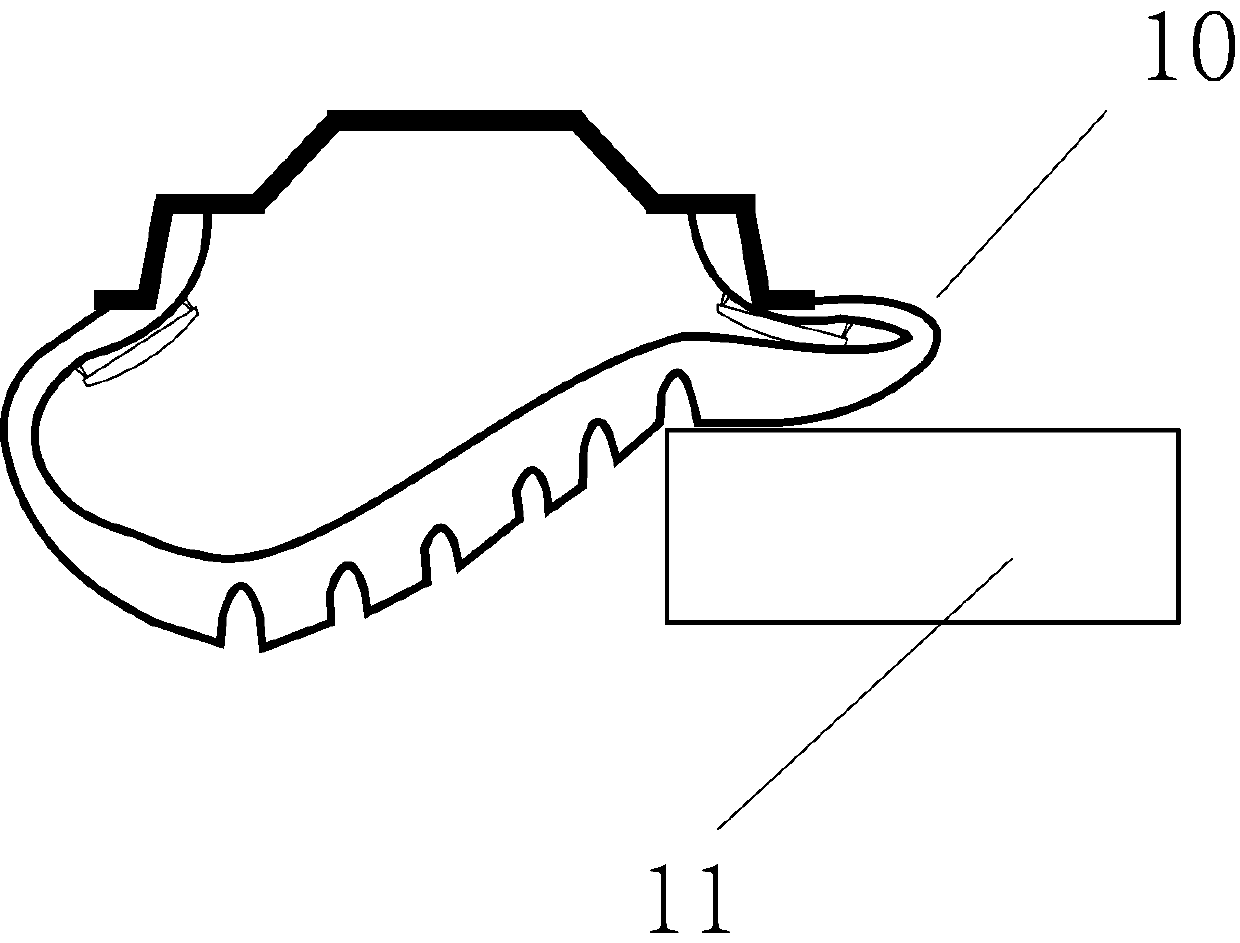

[0032] Embodiment 2: An anti-bulge tire, including a tire 1 and a force-guiding structure 2. The force-guiding structure 2 is located inside the tire 1 and connected to the inner wall 8 of the tire. The force-guiding structure 2 includes a rubber strip 16 and a connecting foot 17. The rubber strip 16 is set at the lower tangent point 21 of the rim edge of the tire 1, connected with the inner wall 8 through the connecting foot 17, and circles the inner wall 8. A tire 1 is provided with at least two force-conducting structures 2, which are located at two rim edges of the tire 1. On the inner wall at 21 places of the lower cut point, the thickness of the rubber strip 16 is 20mm, and the rubber strip 16 adopts natural rubber, such as Figure 6 One end of the connecting foot 17 shown is connected to the rubber strip 16, and the other end is connected to the tire inner wall 8, wherein the connecting foot 17 is connected to the end of the tire inner wall 8 and the end of the connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com