Process for sticking adhesive tape on wire rods

A tape and wire sticking technology, applied in the field of wire sticking tape technology, can solve the problems of high cost of tape sticking, short tape, large manpower demand, etc., and achieve the effects of reducing manpower demand, improving efficiency and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The content of the present invention will be described below in conjunction with specific embodiments.

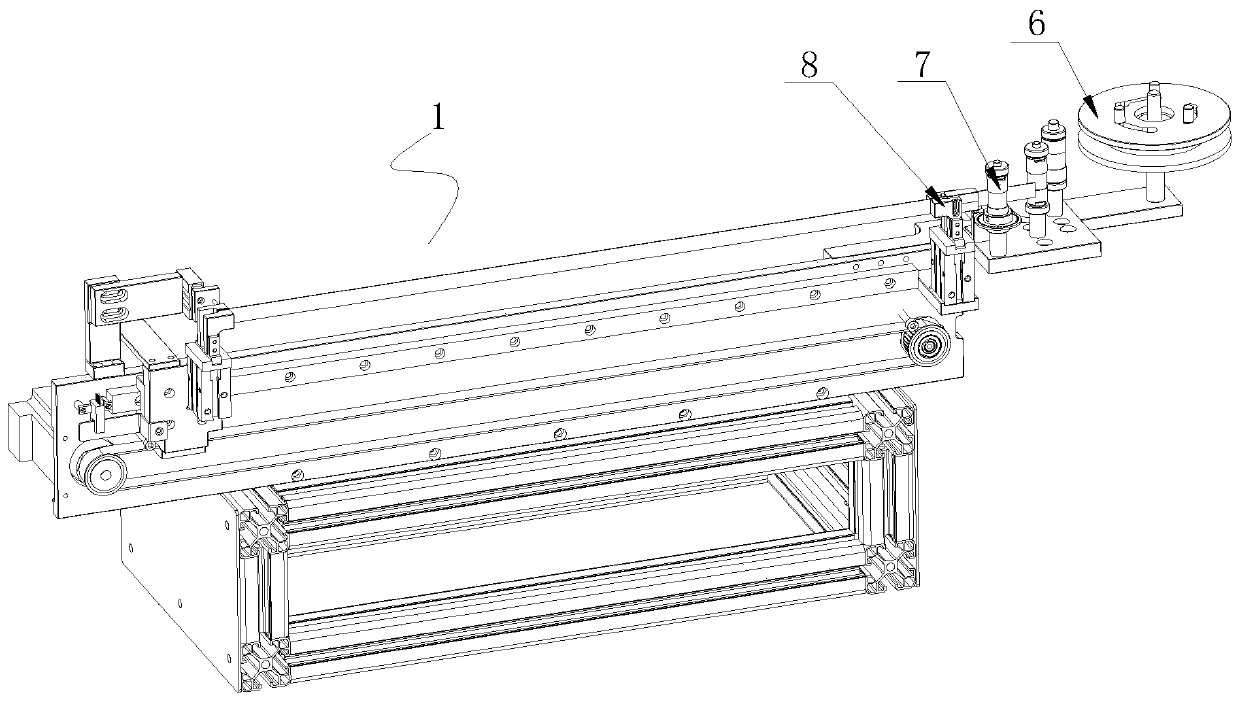

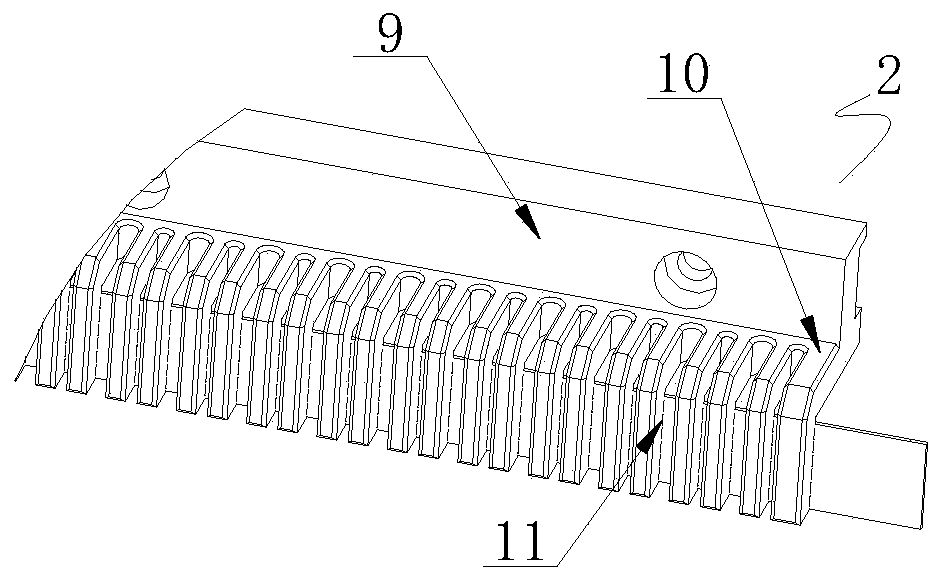

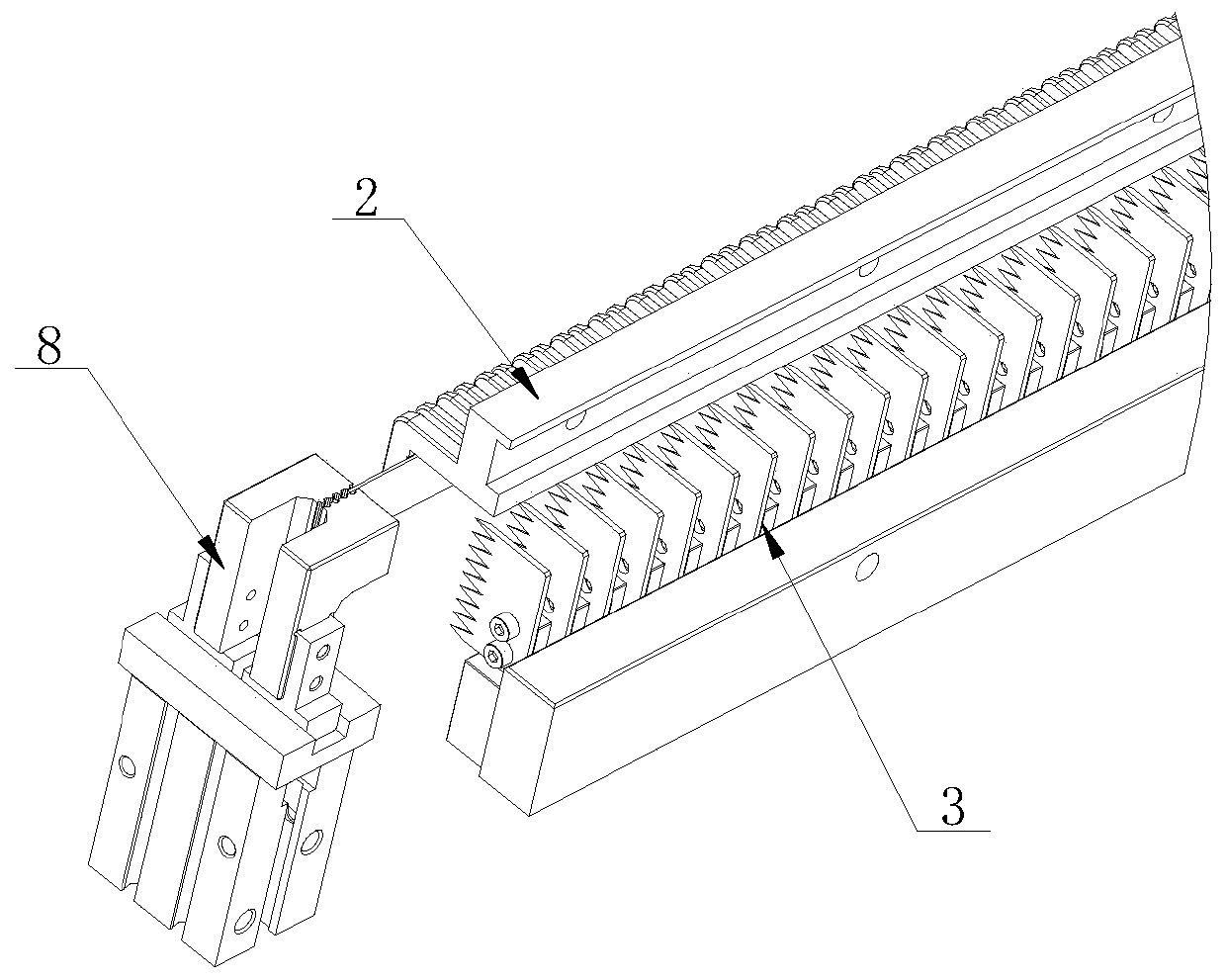

[0017] like Figure 1~5 As shown, the aforesaid wire tape sticking process includes a tape straightening device 1, a transfer plate 2, a cutter group 3, a wire 4 and a shaping clip 5, and the tape straightening device 1 includes a rubber disc 6 and a roller 7 And the fixed clip 8, the rubber disc 6 is horizontally installed at one end of the device, the roller 7 is vertically staggered and installed on the tape straightening device 1 inside the rubber disc 6, and is at the same horizontal position as the rubber disc 6, and the fixed clip 8 is vertically installed on the tape On both sides of the straightening device 1, the tape is pulled out by the rubber disc 6, and the two ends are respectively fixed on the fixing clips 8 on both sides after passing the roller 7. The transfer plate 2 includes a base plate 9 and an ear plate 10, and the base plate 9 is Rectangular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com