Odorless asphalt mixture, preparation method thereof and application of odorless asphalt mixture on pavement

An asphalt mixture and deodorizing technology, which is applied in roads, roads, building insulation materials, etc., can solve the problems of anti-aging and anti-deformation performance and softening point, poor deodorizing effect, poor rheological properties, etc. , to achieve the effects of improving anti-aging performance, optimizing compatibility, and improving the effect of net odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

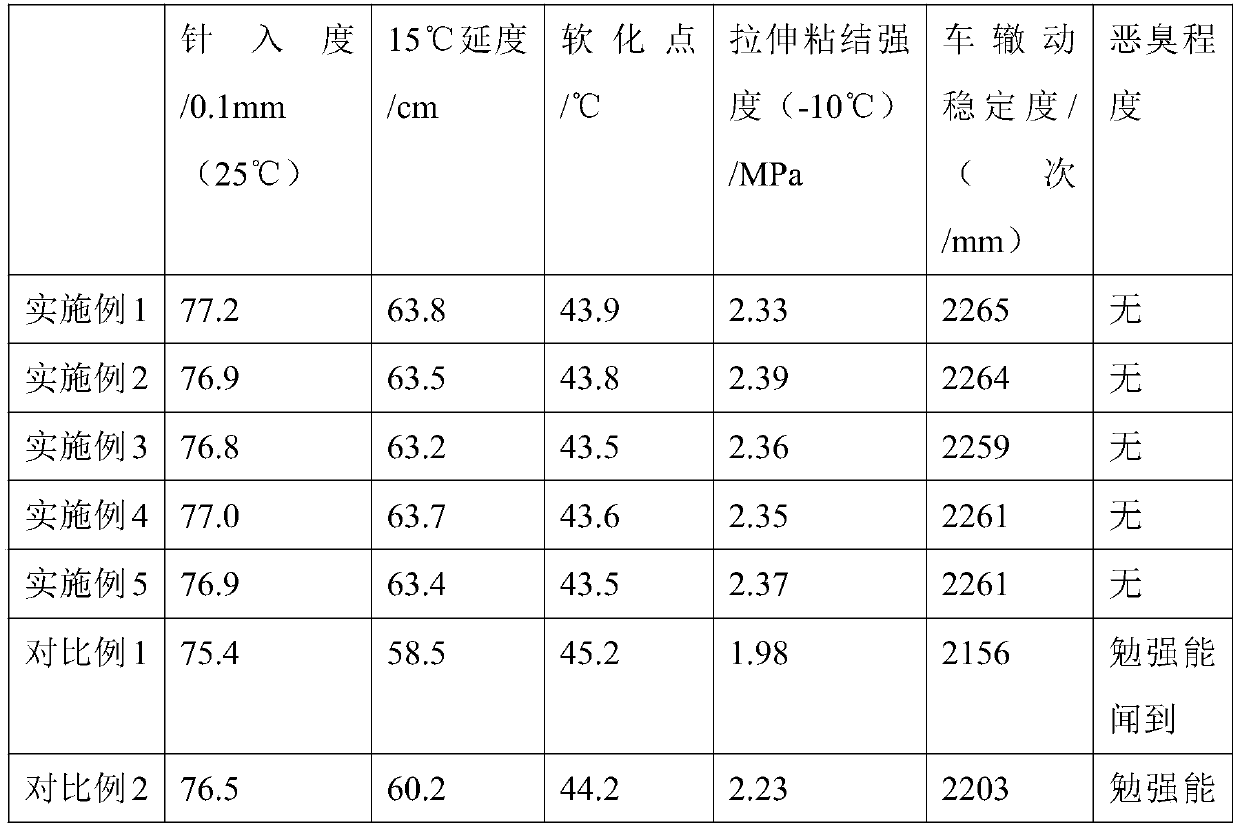

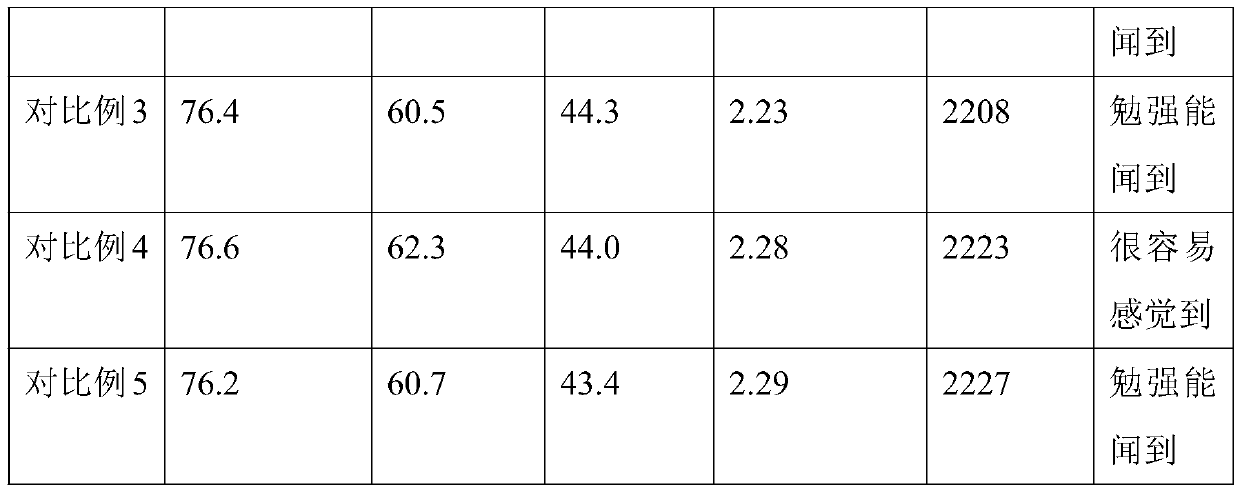

Examples

Embodiment 1

[0021] A preparation method for clean taste asphalt mixture, comprising the steps of:

[0022] (1) Carry out low-temperature plasma modification to graphyne nanomaterials, process graphyne nanomaterials in a low-temperature plasma generator, make the surface of graphyne nanomaterials introduce oxygen-containing functional groups, obtain modified graphyne; modify The graphyne is dispersed in an anhydrous ethanol solution, and ultrasonically dispersed to obtain a graphyne modified liquid;

[0023] (2) the magnesium hydroxide of 10 weight parts, the TEOS of 1 weight part, 3 weight parts vegetable oils, the SBS of 10 weight parts, the odor suppressant of 2 weight parts mix, obtain asphalt composite modifier;

[0024] (3) Heat the base asphalt to 160°C, then add asphalt composite modifier and graphyne modified solution, the weight ratio of base asphalt, asphalt composite modifier and graphyne modified solution is 100:3:20, shear Cut and heat up to 190°C, shear and swell for 1 hour...

Embodiment 2

[0030] A preparation method for clean taste asphalt mixture, comprising the steps of:

[0031] (1) Carry out low-temperature plasma modification to graphyne nanomaterials, process graphyne nanomaterials in a low-temperature plasma generator, make the surface of graphyne nanomaterials introduce oxygen-containing functional groups, obtain modified graphyne; modify The graphyne is dispersed in an anhydrous ethanol solution, and ultrasonically dispersed to obtain a graphyne modified liquid;

[0032] (2) the magnesium hydroxide of 10 weight parts, the TEOS of 1 weight part, 3 weight parts vegetable oils, the SBS of 10 weight parts, the odor suppressant of 1 weight part mix, obtain asphalt composite modifier;

[0033] (3) Heat the base asphalt to 160°C, then add asphalt composite modifier and graphyne modified solution, the weight ratio of base asphalt, asphalt composite modifier and graphyne modified solution is 100:3:20, shear Cut and heat up to 190°C, shear and swell for 1 hour,...

Embodiment 3

[0039] A preparation method for clean taste asphalt mixture, comprising the steps of:

[0040](1) Carry out low-temperature plasma modification to graphyne nanomaterials, process graphyne nanomaterials in a low-temperature plasma generator, make the surface of graphyne nanomaterials introduce oxygen-containing functional groups, obtain modified graphyne; modify The graphyne is dispersed in an anhydrous ethanol solution, and ultrasonically dispersed to obtain a graphyne modified liquid;

[0041] (2) the magnesium hydroxide of 10 weight parts, the TEOS of 1 weight part, 3 weight parts vegetable oils, the SBS of 10 weight parts, the odor suppressant of 2 weight parts mix, obtain asphalt composite modifier;

[0042] (3) Heat the base asphalt to 170°C, then add asphalt composite modifier and graphyne modified solution, the weight ratio of base asphalt, asphalt composite modifier and graphyne modified solution is 100:3:20, shear Cut and heat up to 190°C, shear and swell for 1 hour,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com