Organosilicon liquid optical adhesive and use method thereof

An optical glue and silicone technology, applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of high refractive index and loss of mechanical properties of silica gel, and achieve high reactivity and compatibility. , Increase the effect of aging resistance

Active Publication Date: 2020-06-05

DONGGUAN POWERBOND NEW MATERIALS TECH DEV

View PDF8 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Although the invention obtains an optical adhesive with a high degree of yellowing resistance by abandoning the benzene ring structure in the structure, it loses most of its mechanical properties at the same time; at the same time, the silica gel has a high refractive index

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

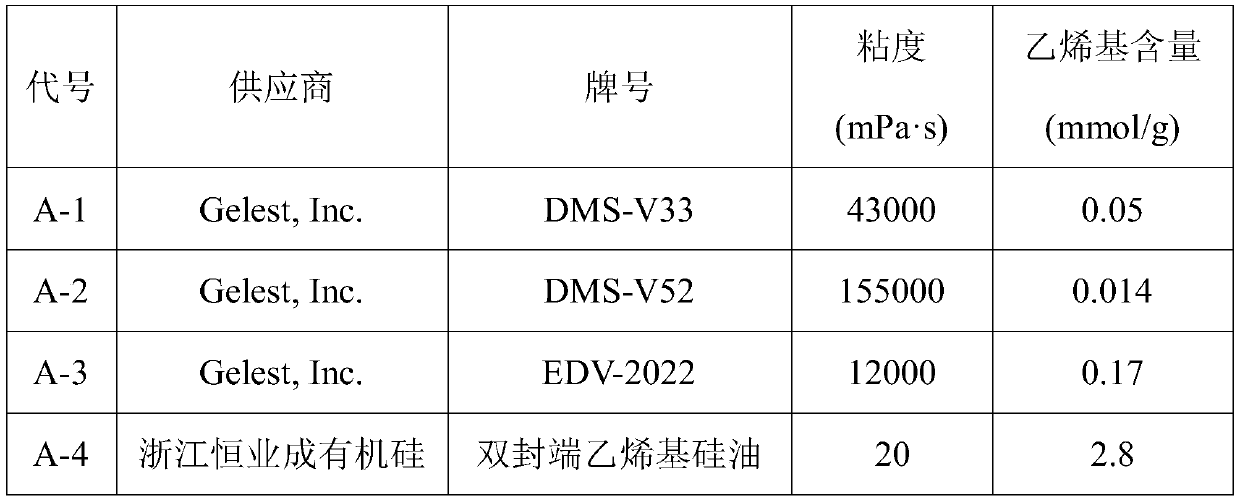

Embodiment 1-6

[0091] Prepare silicone liquid optical adhesive according to the components shown in Table 1.

[0092] Table 1

[0093]

[0094]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides an organosilicon liquid optical adhesive and a use method thereof. The adhesive comprises a frame adhesive and a surface adhesive, wherein testing is conducted according to a standard GB / T 614-2006 chemical reagent refractive index measurement general method, and the refractive index difference value of the frame adhesive and the surface adhesive is smaller than or equal to0.005. The refractive index difference between the frame adhesive and the surface adhesive in the organosilicon liquid optical adhesive is extremely small, the chemical compatibility is high, and it can be ensured that no trace exists on the interface of the frame adhesive and the surface adhesive after attachment; in addition, the frame adhesive and the surface adhesive have excellent aging resistance and yellowing resistance.

Description

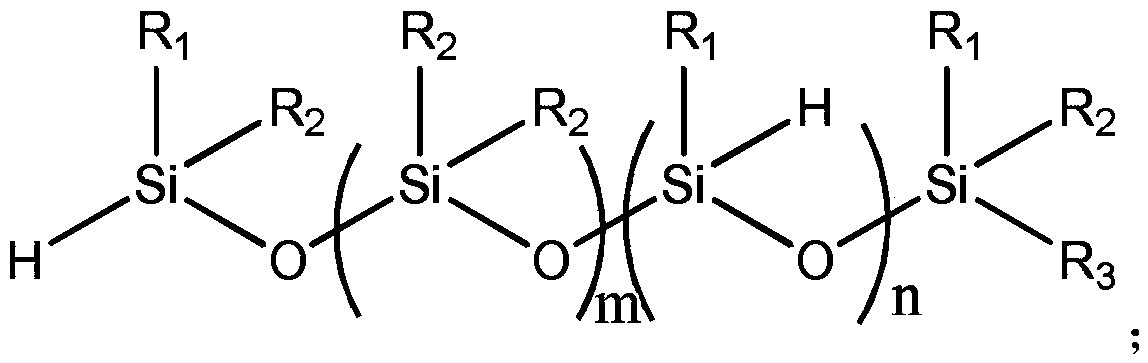

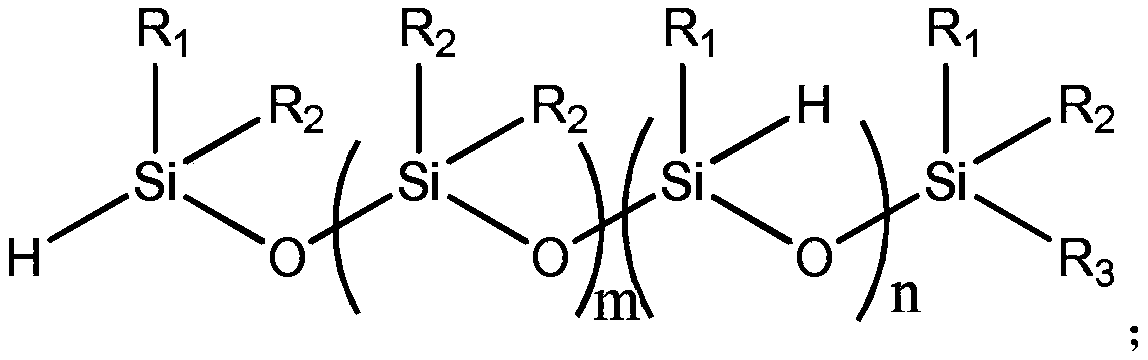

technical field [0001] The invention belongs to the technical field of adhesives, and relates to a liquid organic silicon optical adhesive and a use method thereof. Background technique [0002] Full lamination refers to the use of liquid optical glue to seamlessly bond the display module with the touch panel / cover to reduce light loss and glare, increase contrast, and improve display effects. It is also dustproof, waterproof, and stress buffering. technology with many effects. At present, the full-fit liquid optical adhesives on the market all adopt the form of "frame glue + surface glue", and the joint use of frame glue and surface glue has brought new interface problems. Due to the poor compatibility between the frame glue and the surface glue, the interface is obvious, which affects the display effect of the lamination; at the same time, due to the difference in refractive index between the frame glue and the surface glue, the cured screen is in the gap between the fram...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09J183/07C09J183/08C09J11/06C09J11/08

CPCC09J183/04C09J11/06C09J11/08C08L2205/03C08L2205/035C08L2205/025C08L2201/08C08L83/04C08K5/5425C08K5/053

Inventor 黎松陈富强成浩冠洪亮綦俊杰张小中刘兆辉

Owner DONGGUAN POWERBOND NEW MATERIALS TECH DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com